Rolling bearing system of automobile motor

A technology of rolling bearings and motor shafts, which is applied in the direction of electric components, casings/covers/supports, electrical components, etc., can solve problems such as reducing the desire to purchase new energy vehicles, increasing the failure rate of new energy vehicles, and shortening the maintenance time of motors. Achieve the effect of light weight, less parts and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

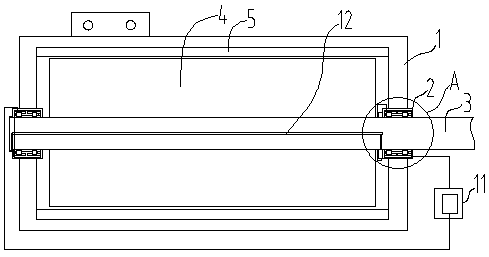

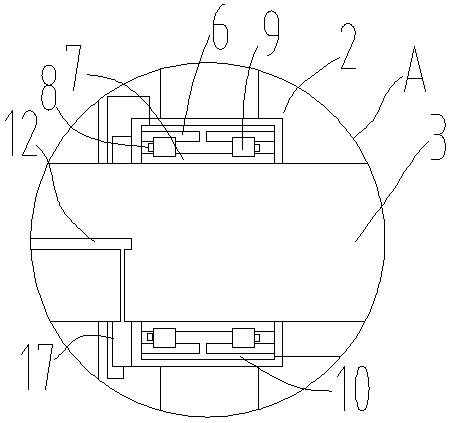

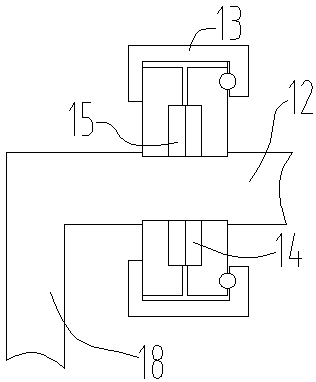

[0025] Such as figure 1 , figure 2 and image 3 The rolling bearing system of the automobile motor shown includes a housing 1 of the motor, a bearing component 2 and a motor shaft 3 provided with a first oil passage 12 along the axial direction, and the two opposite surfaces of the housing 1 are respectively provided with bearing components 2 , the motor shaft 3 is installed with the bearing part 2 to form a support for the motor shaft. The upper parts of the two bearing parts 2 are respectively provided with oil inlet holes 9; the bottom of a bearing part 2 is provided with an oil groove 10 connected with an oil pool 11 , the upper oil inlet hole 9 is connected to the liquid outlet of the first oil passage 12, the oil inlet hole 9 on the upper part of another bearing part 2 is connected to the oil pool 11, and the lower part of the bearing part 2 is also provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com