Patents

Literature

31results about How to "Reliable cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

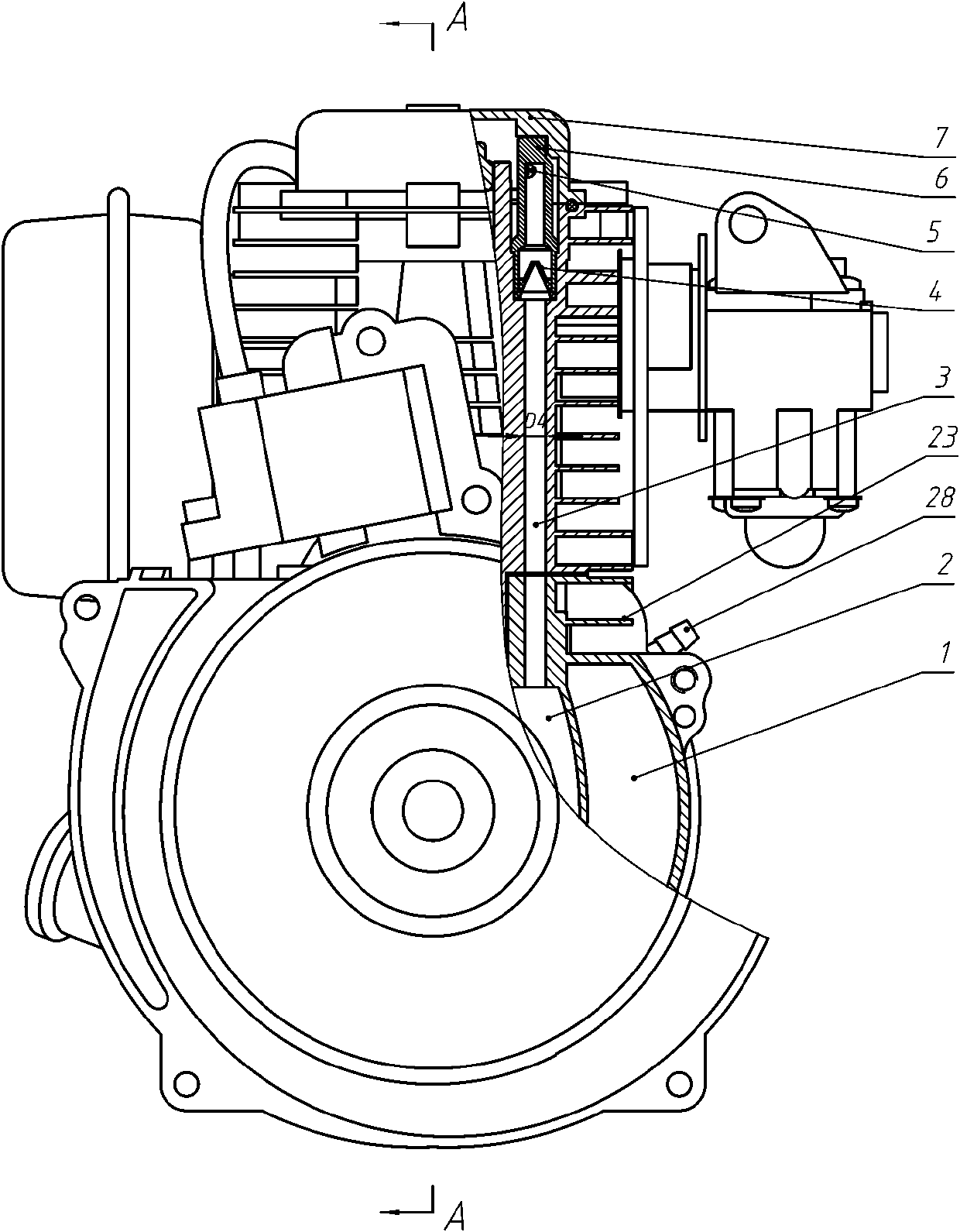

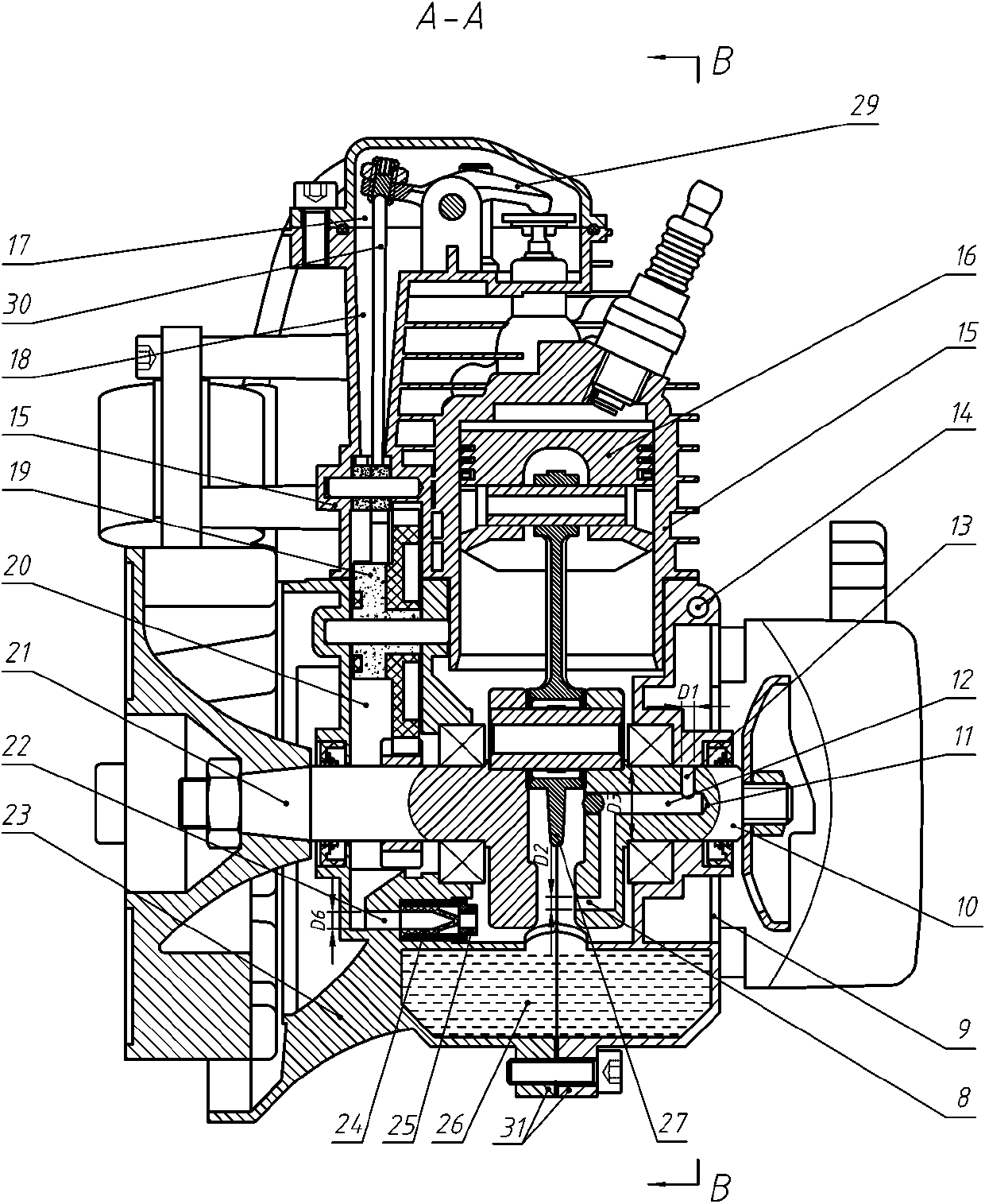

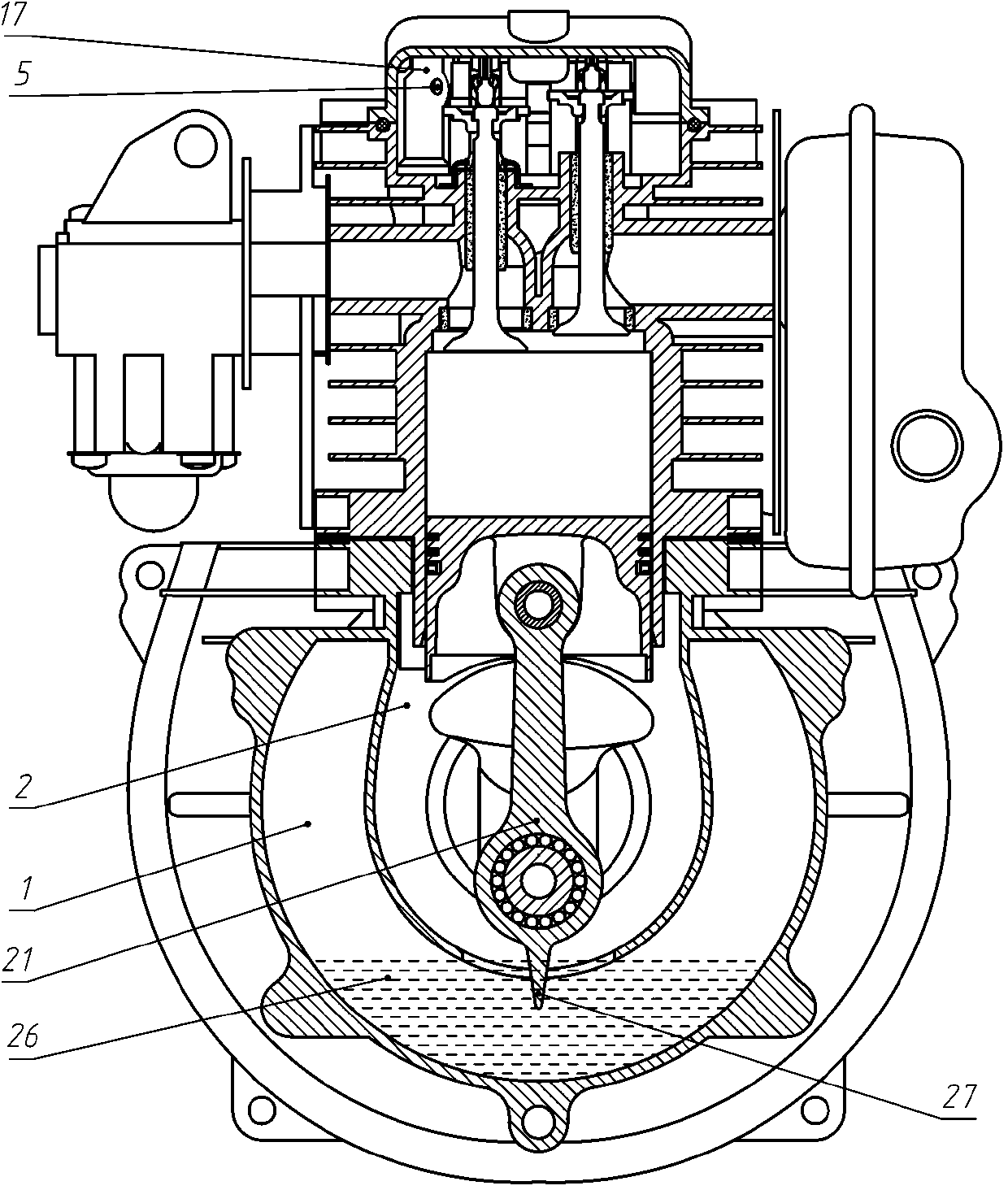

Small four-stroke gasoline engine with oil mist lubrication

InactiveUS7243632B2Easy constructionImprove mobilityLubrication of auxillariesDrip or splash lubricationImpellerReciprocating motion

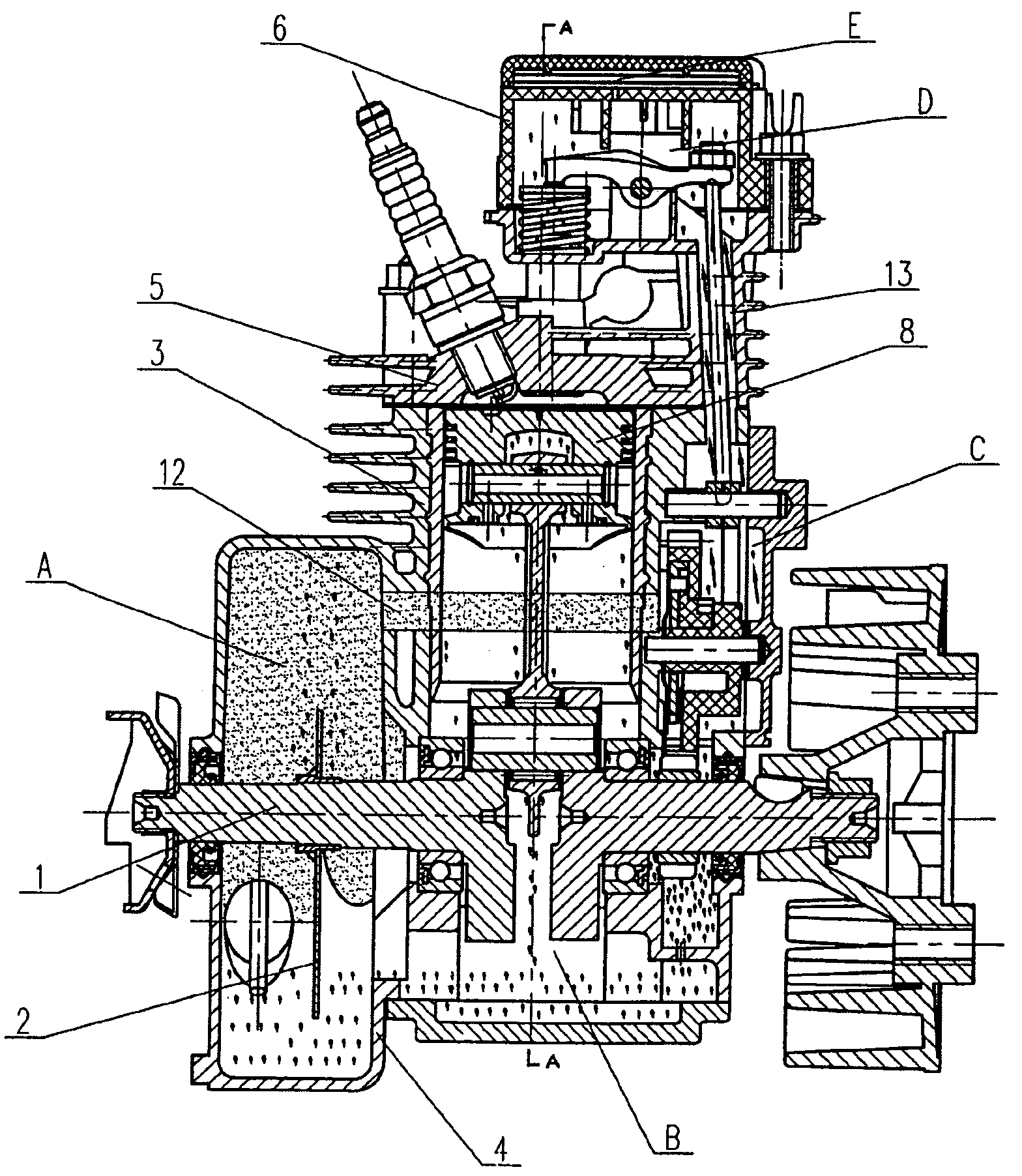

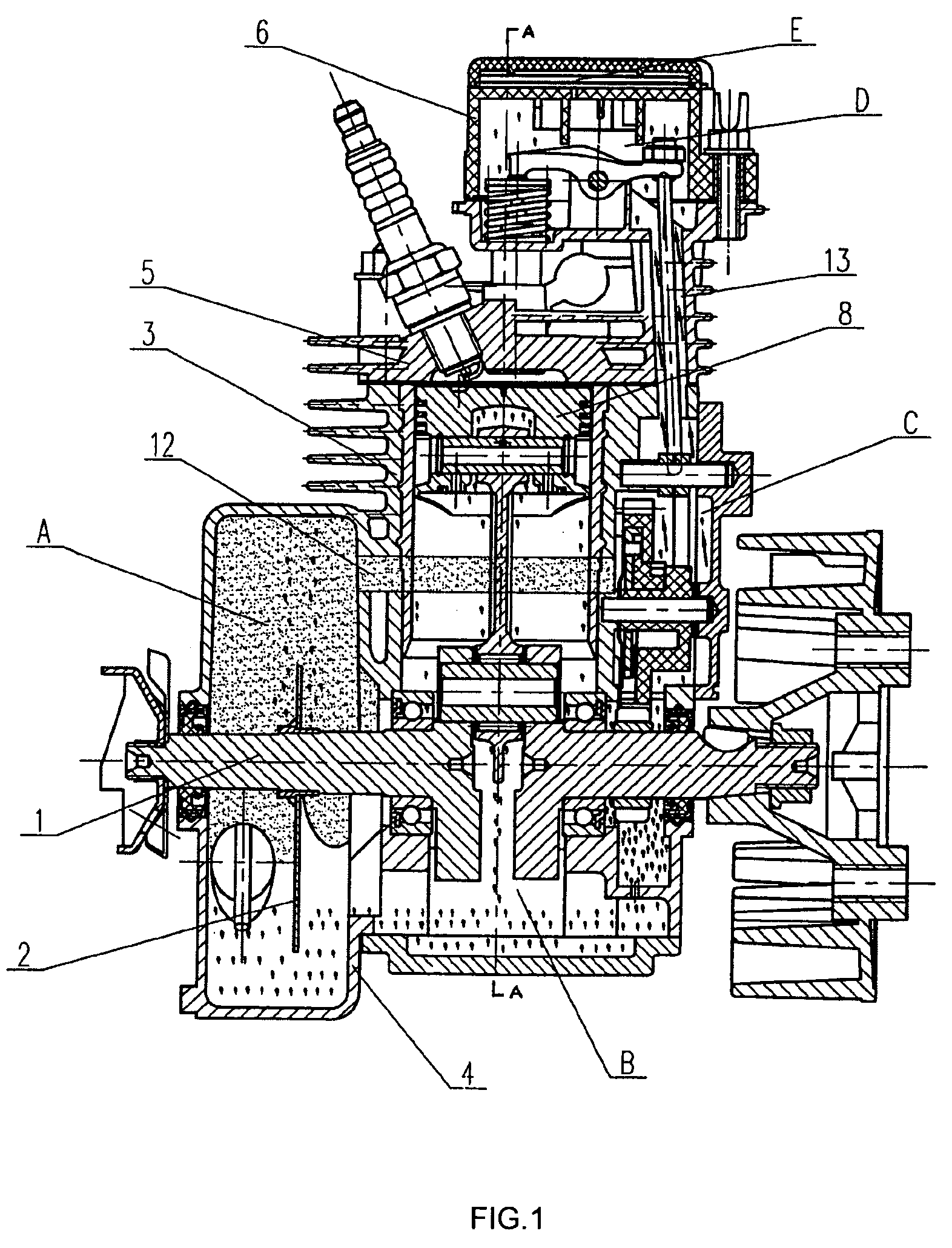

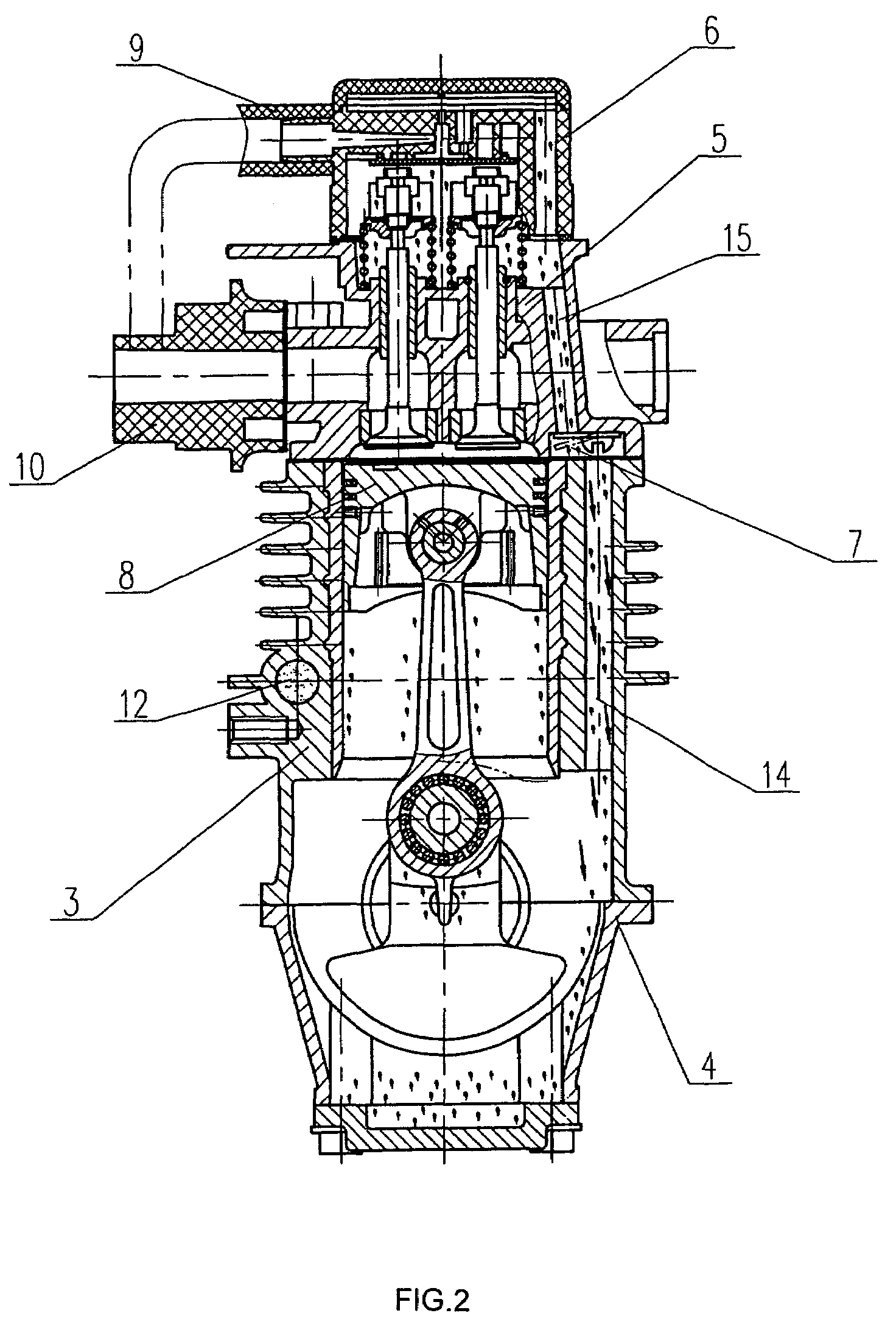

The present invention relates to a small four-stroke gasoline engine with oil mist lubrication. The lubrication oil way of the engine includes a crankshaft chamber B, a camshaft chamber C, an upper rocker arm chamber D and a condensation chamber E. The camshaft chamber C communicates with the upper rocker arm chamber D via a tappet cavity 13. The upper rocker arm chamber D communicates with the condensation chamber E. An oil mist chamber A is surrounded by an upper case body 3 and a lower case body 4 at the side of the crankshaft chamber B, the bottom of the oil mist chamber A communicates with the crankshaft chamber B. An oilsplash impeller 2 is fixed on a crankshaft, which extends into the oil mist chamber A. An oil way 12 is provided on the upper case body 3 between the oil mist chamber A and the camshaft chamber C. An oil return way 15 is provided on a cylinder head assembly 5. An oil return way 14 is provided on the upper case body 3. An upper interface of the oil return way 15 communicates with the upper rocker arm chamber D, a lower interface of the oil return way 15 communicates with the oil return way 14, and a lower interface of the oil return way 14 communicates with the crankshaft chamber B. The conventional lubricating mode is changed by the structure of the invention, which makes use of the pressure change during the reciprocating movement of a piston assembly 8 to attain the circulation of oil. The structure is simple, reliable in operation and has small consumption in power.

Owner:HU JI RONG NO

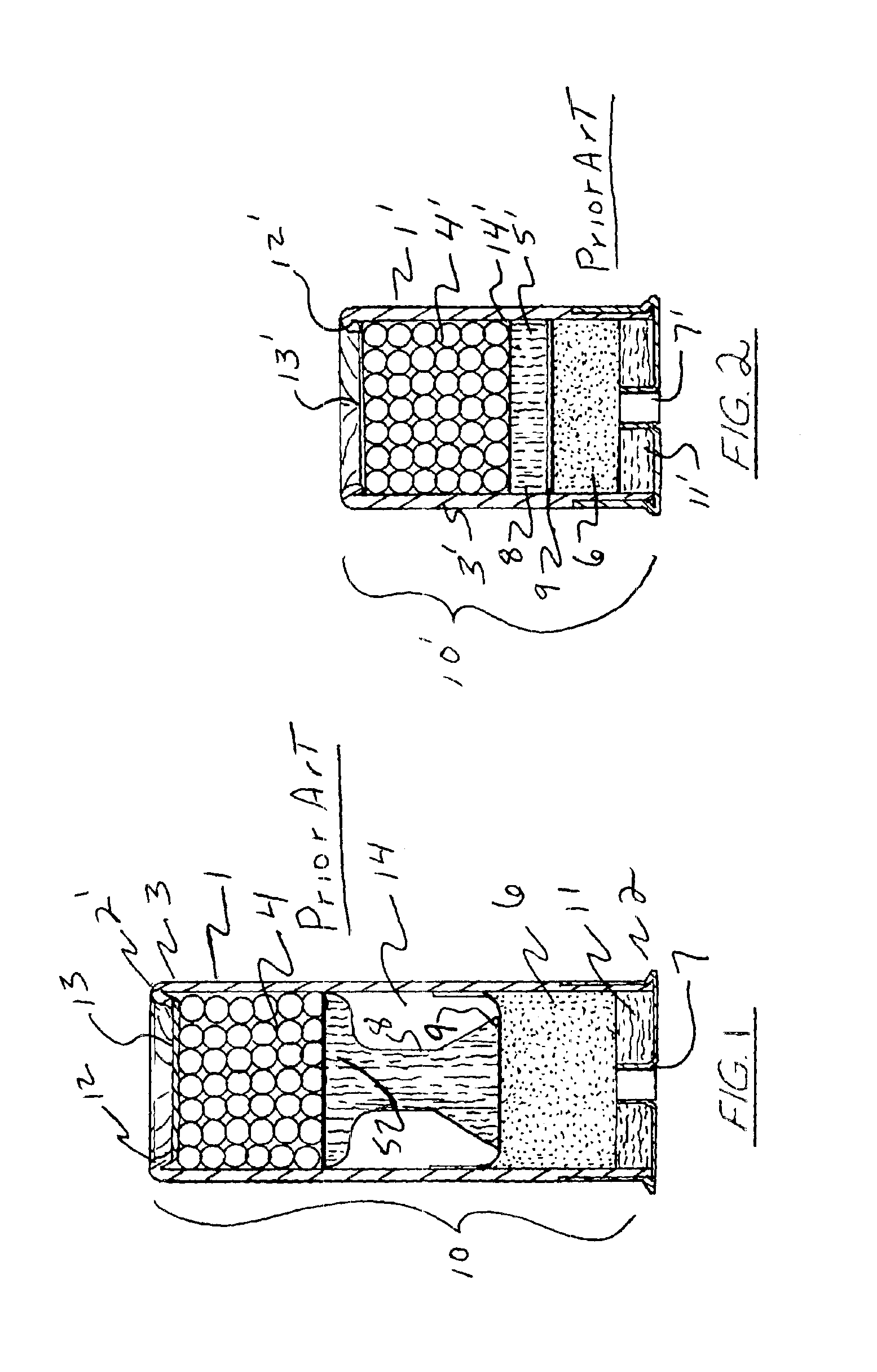

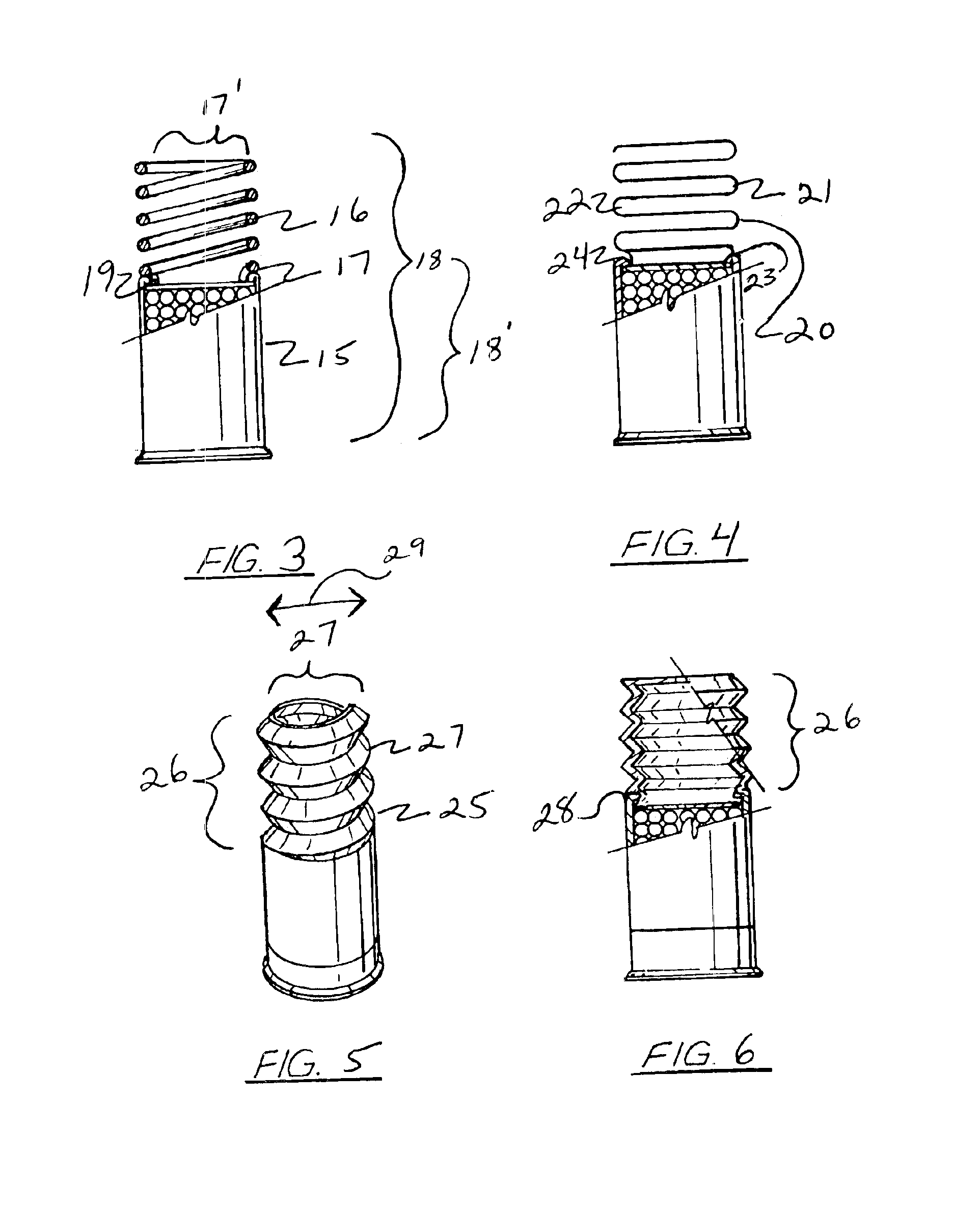

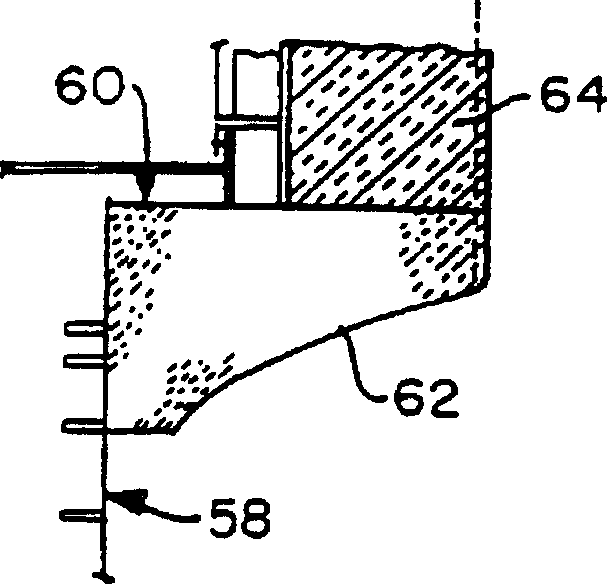

Compressible shot shell

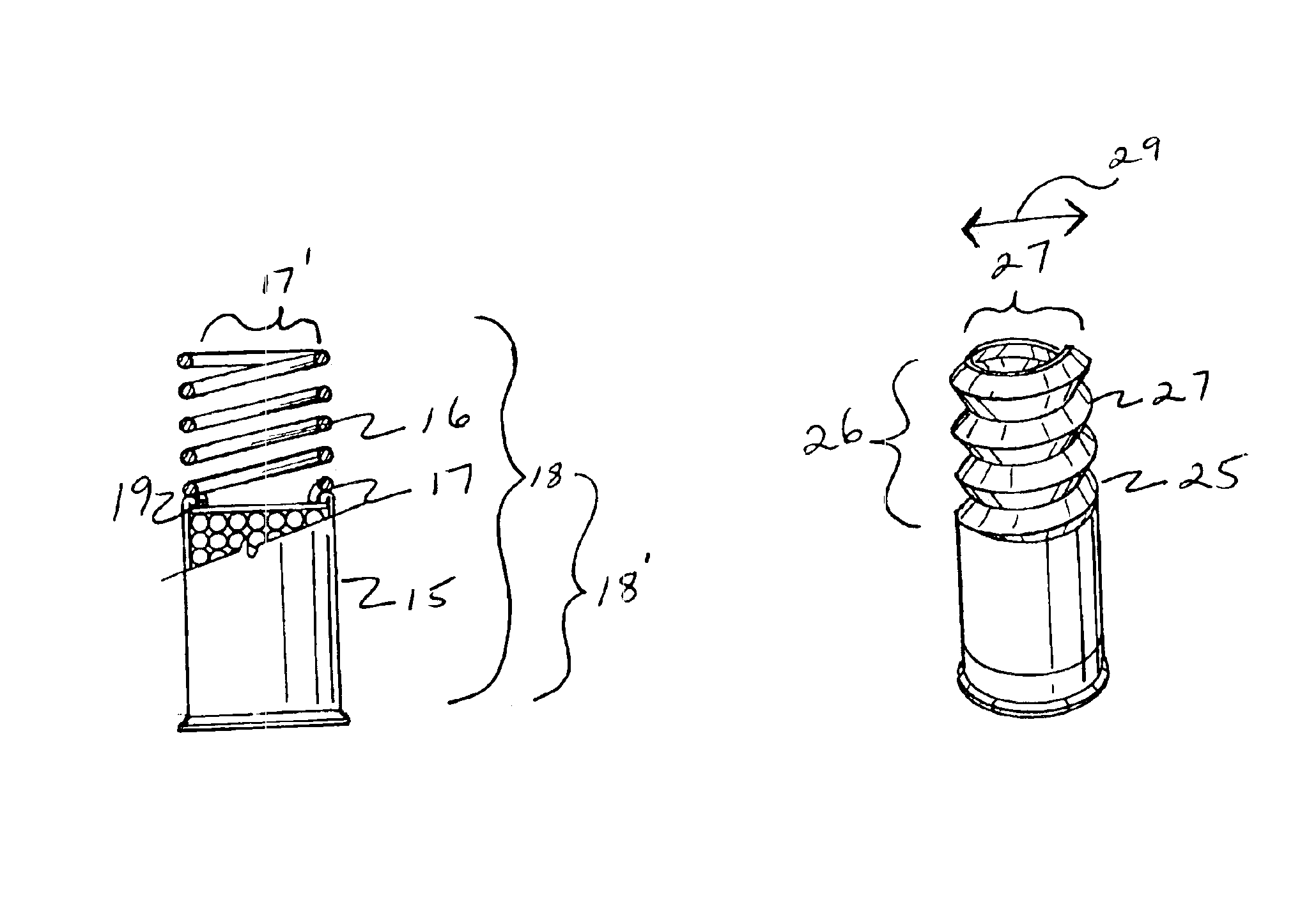

InactiveUS6860207B1Facilitate increased shot shell capacityPlace stableAmmunition projectilesSafety arrangementLoad cycleSemi automatic

A shot shell such as would be utilized in a shotgun or the like, wherein the cartridge forming the shell has a collapsible extension removably or permanently engaging the shot end of the cartridge, with the cartridge configured to provide a un-compressed length of, for example, 2.50 inches (the minimum length of shell for conventional automatic or semi-automatic, magazine fed shotguns. The collapsible extension is configured to be compressed when placed in a spring-fed magazine, so as to provide increased magazine capacity when compared to standard length shells, while expanding when removed by from the magazine during a loading cycle, so as to facilitate reliable placement of the shell into the breach from the magazine. The collapsible extension in the loaded cartridge of the present invention is configured to be ejected from the barrel upon firing of the cartridge. The present system thereby provides a means to increase the capacity of conventional automatic or semi-automatic (i.e., pump actuated) shotguns, while reducing the likelihood of jamming or malfunction due to utilizing shells which are shorter than the firearm was designed to process.

Owner:ROBERTSON THOMAS W

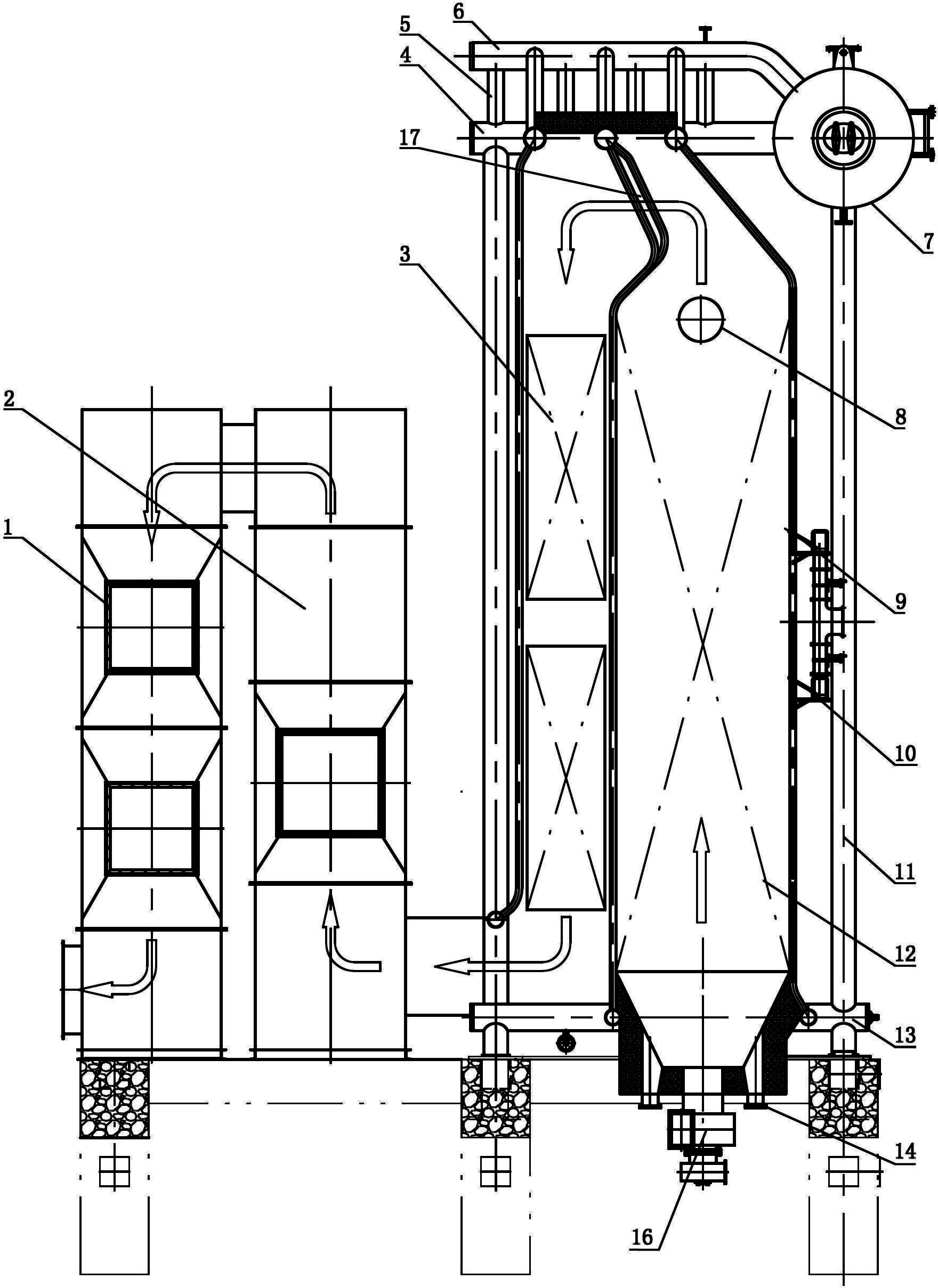

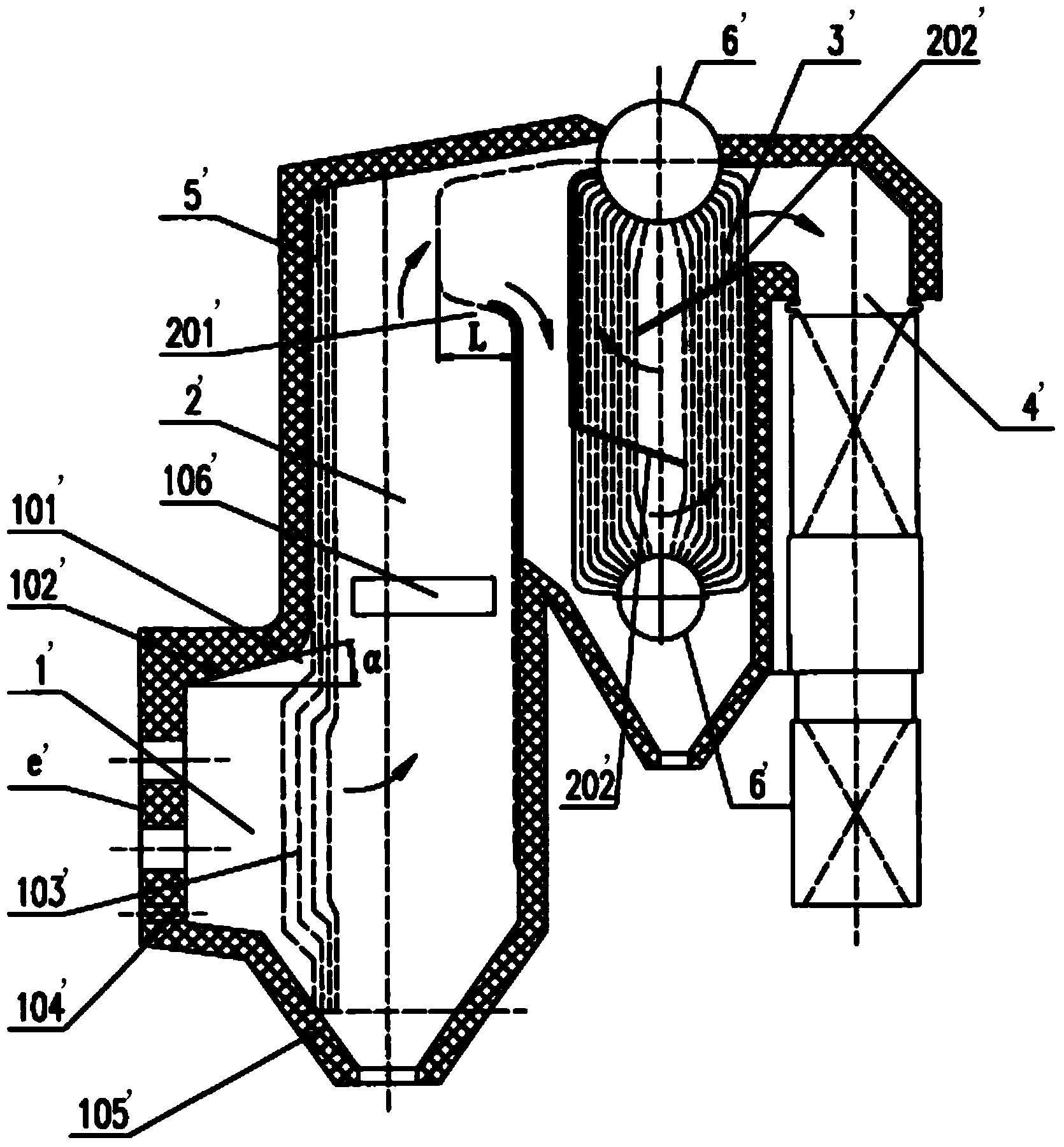

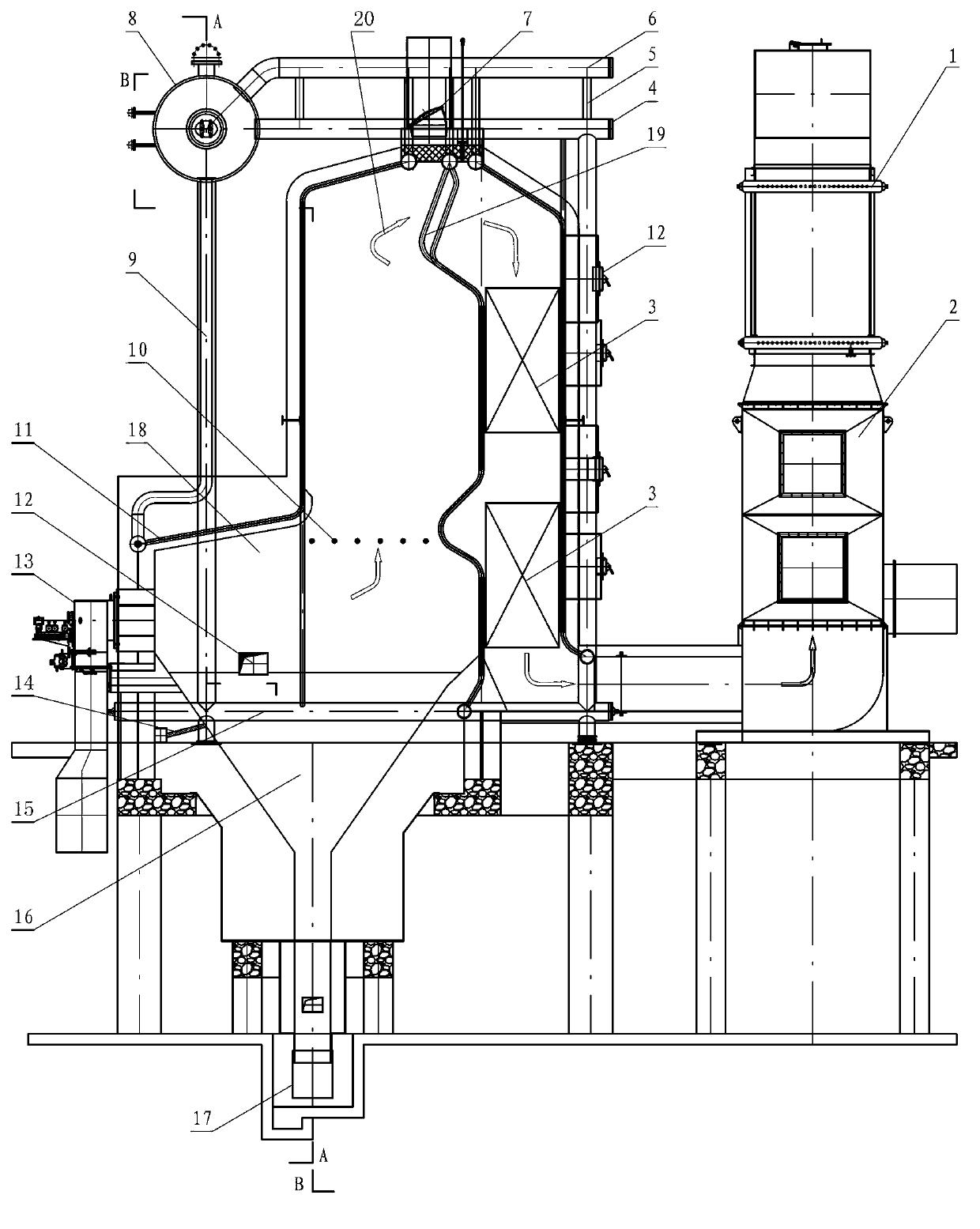

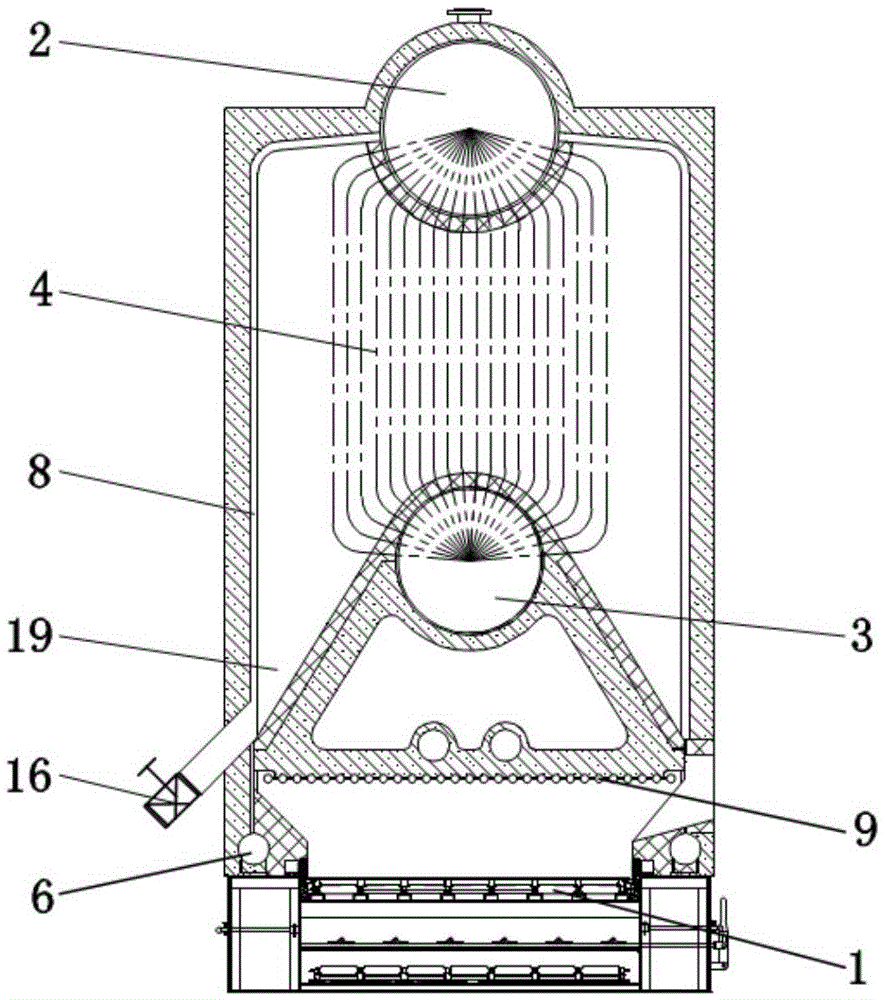

Vertical coal dust corner tube boiler

InactiveCN102644911ACompact structureStructure, compact arrangement of four cornersSteam boilersAir preheaterCoal dust

The invention discloses a vertical coal dust corner tube boiler, which comprises a burner, a boiler body, an air preheating device, a waste heat water tank, a convection bank, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of the boiler body, and the upper collecting box and the top collecting box are arranged on top of the boiler body and communicated through a steam communicating pipe. The vertical coal dust corner tube boiler is characterized in that the burner is arranged at the bottom of the boiler body which adopts a vertical film type water cooling wall structure, four lowering pipes are arranged at four corners, and two ends of the lowering pipe and the film type water cooling wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged outside the film type water cooling wall, the top of the convection tube bundle is communicated with a boiler chamber smoke outlet, and the bottom of the convection tube bundle is communicated with the waste heat water tank. The vertical coal dust corner tube boiler has the advantages of being compact in integral structure, simple in appearance display, small in covered area, low in steel consumption, big in boiler water circulation pressure difference and safe and reliable in water circulation and the like.

Owner:HANGZHOU JUNENG BOILER

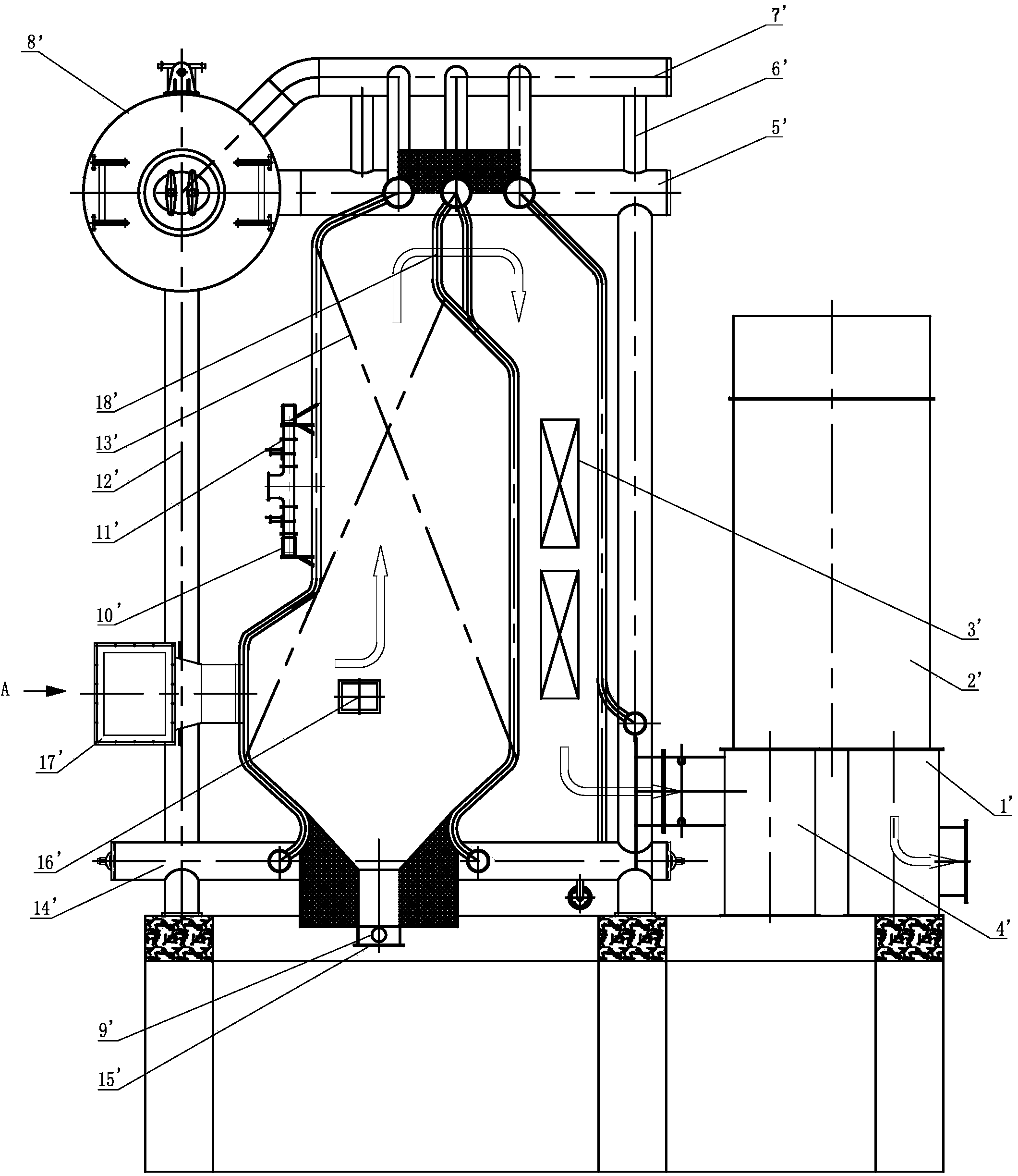

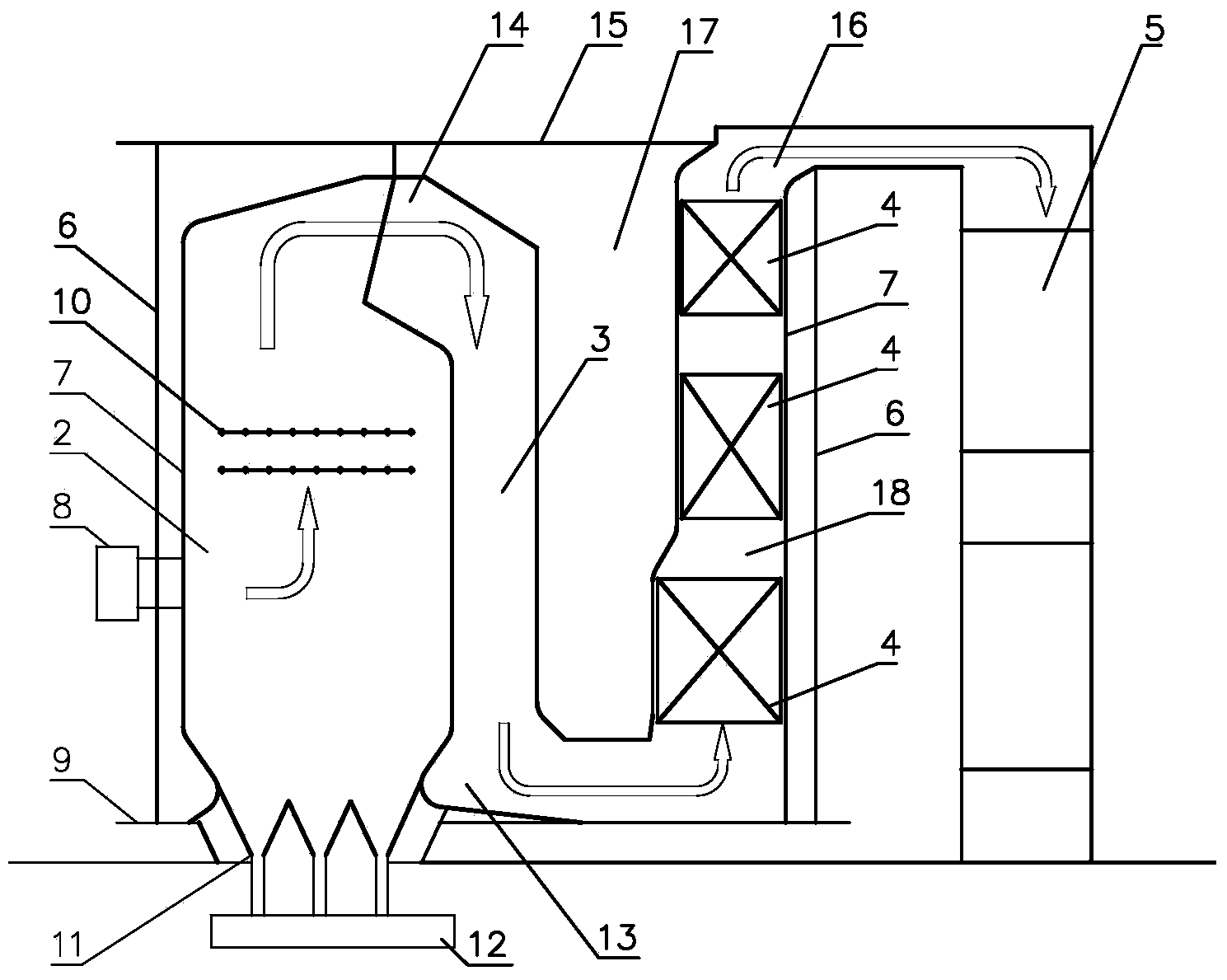

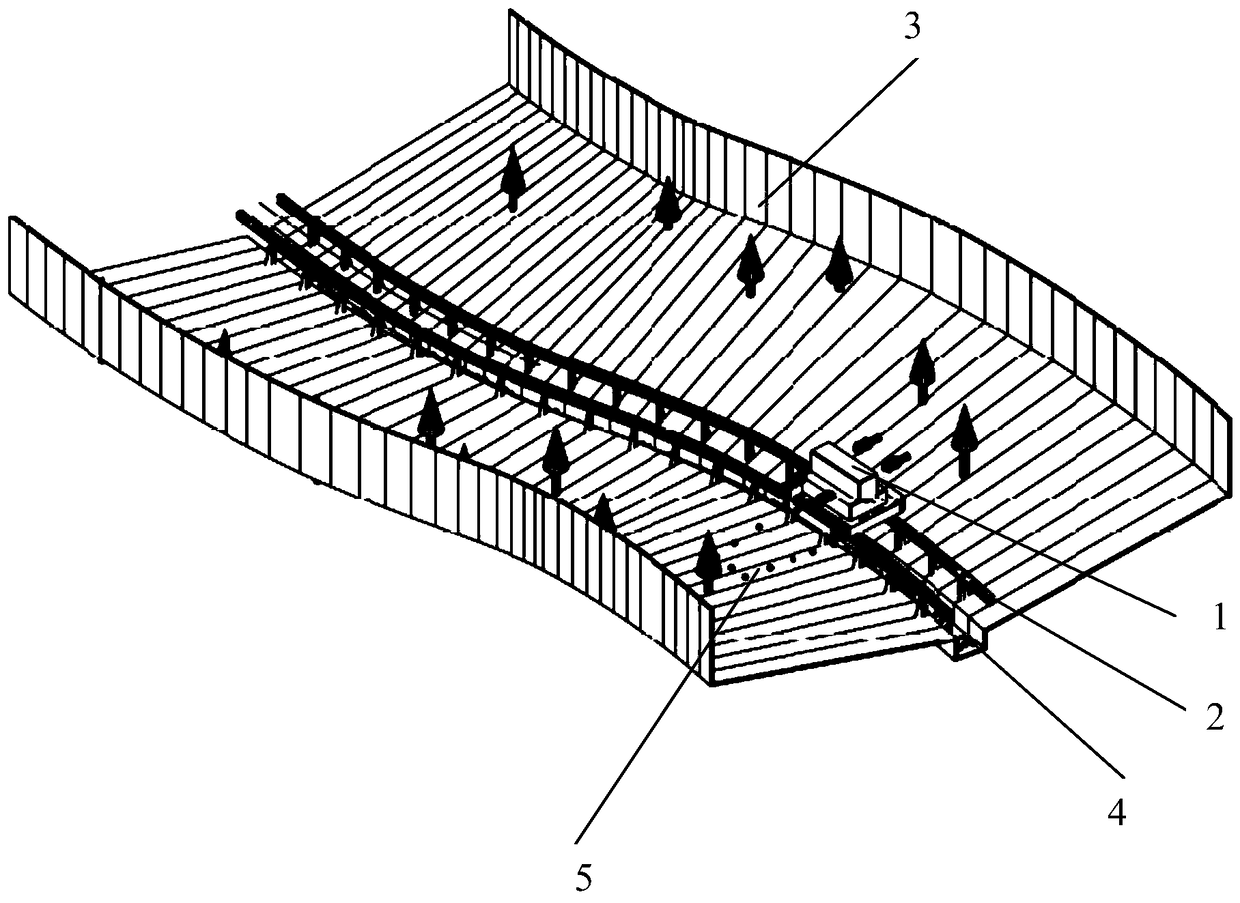

Three-return-stroke powder steam boiler

InactiveCN104359099AReduce generationStop cokingFluidized bed combustionSteam boilersCombustorFlue gas

The invention discloses a three-return-stroke powder steam boiler. The three-return-stroke powder steam boiler comprises a boiler barrel, a hearth, a burnout chamber, a convection tube bundle, tail heat exchange equipment, a combustor, a slag falling device, a lower header and an upper header, wherein the lower header is arranged at the bottom of a boiler body; the upper header is arranged at the top of the boiler body; the combustor is arranged at the front part, the top, the bottom or the side part of the hearth of the boiler; the boiler body has a full-film type water-cooled wall structure, and four main downcomers are arranged at four corners; the convection tube bundle is arranged in a convection tube bundle flue, the convection tube bundle flue is longitudinally arranged, and the height of the convection tube bundle flue is equal to that of the hearth; the upper and lower ends of the convection tube bundle, the main downcomers and a film type water-cooled wall are communicated with the upper header and the lower header respectively; the burnout chamber and the hearth are longitudinally arranged abreast in a back-to-back way, and the height of the burnout chamber is equal to that of the hearth; the hearth, the burnout chamber, the convection tube bundle flue and the tail heat exchange equipment are sequentially conducted in series; two-stage combustion-supporting and denitration secondary air is distributed in the hearth. The three-return-stroke powder steam boiler has the characteristics of long flue gas flow, complete fuel combustion and high heat exchange efficiency.

Owner:HANGZHOU JUNENG BOILER

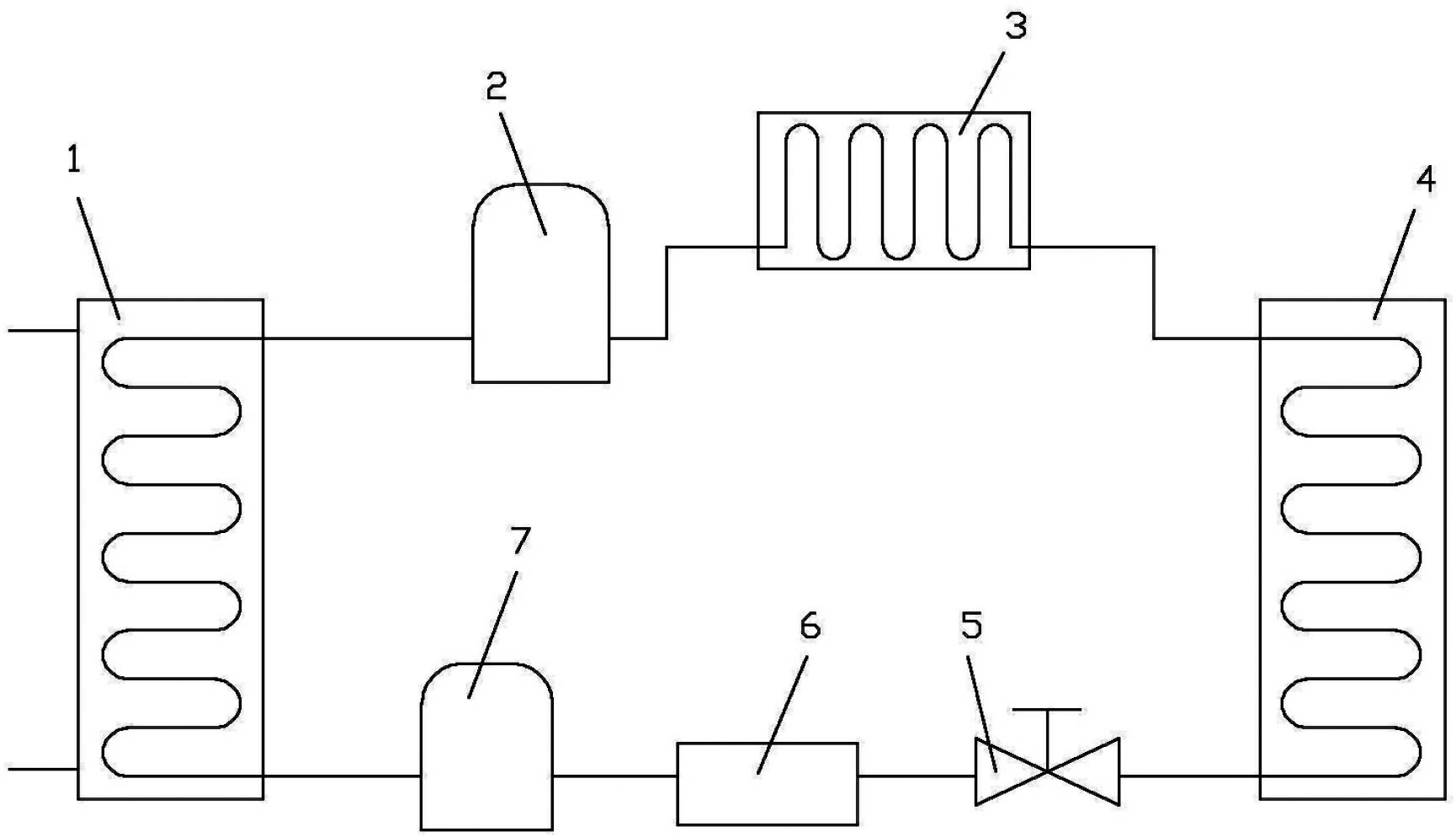

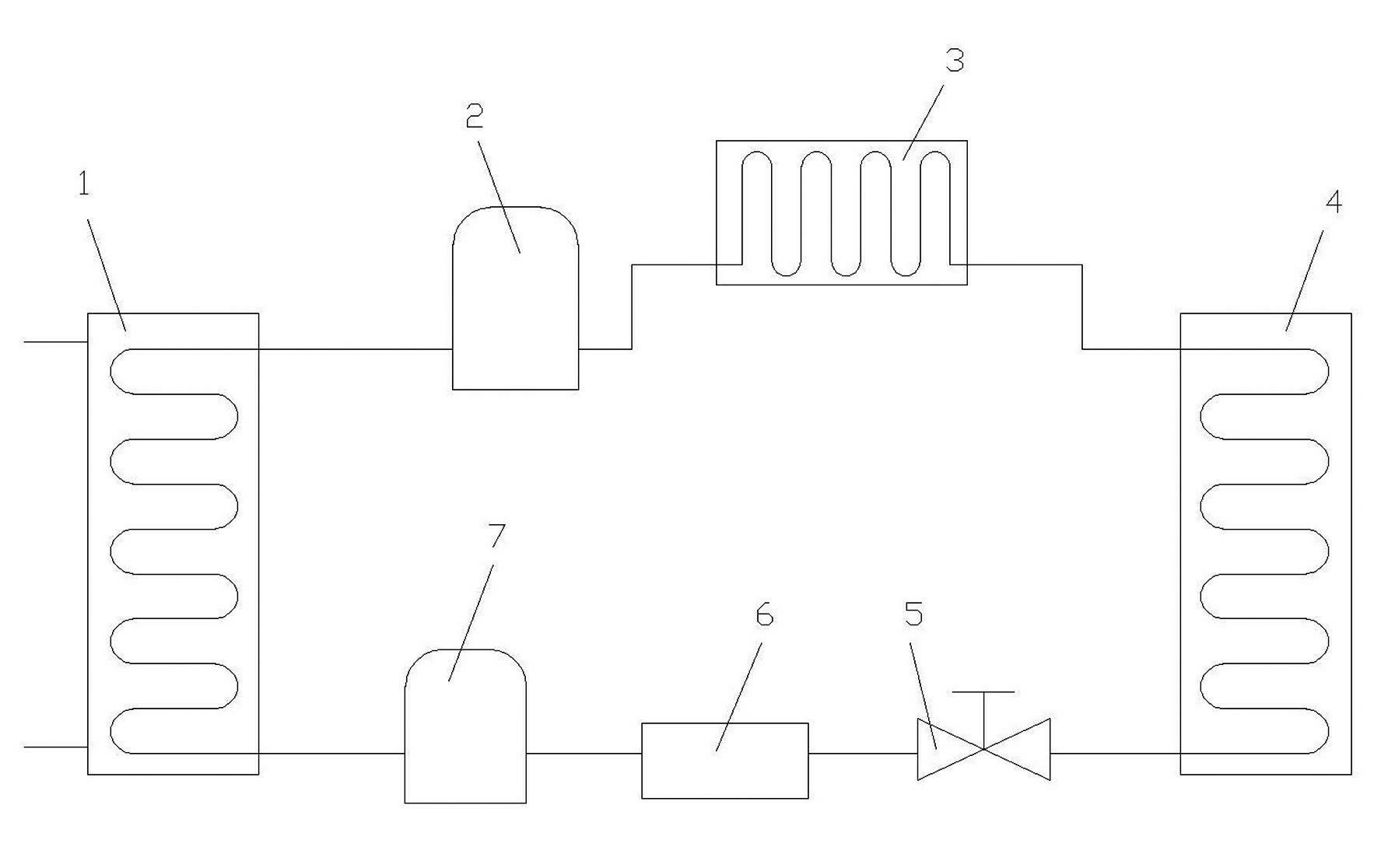

Air/water source heat pump unit

InactiveCN102538303AFast evaporationEfficient evaporationHeat pumpsWater source heat pumpThermal energy

The invention discloses an air / water source heat pump unit which is capable of adapting to the environment with lower temperature to work, and comprises a condenser, a compressor, an evaporator, an expansion valve, a filter and a liquid storage tank, wherein the condenser, the compressor, the evaporator, the expansion valve, the filter and the liquid storage tank are sequentially connected in series, so that a system can be formed; and a solar thermal collector is connected between the compressor and the evaporator in series. As a structure that the solar thermal collector is connected between the compressor and the evaporator in series is adopted by the air / water source heat pump unit, refrigerant gas which flows out from the evaporator and obtains the air / water source energy flows through the solar thermal collector, the heat energy is transmitted into the compressor, more higher energy can be obtained by the refrigerant working medium in the compressor, and the refrigerant working medium is rapidly and efficiently evaporated to be gas. After the solar thermal collector is adopted, the reliable circulation of the unit can be guaranteed, so that the heat pump unit can be used for heating in the season of severe winter in most parts of the north.

Owner:申建光

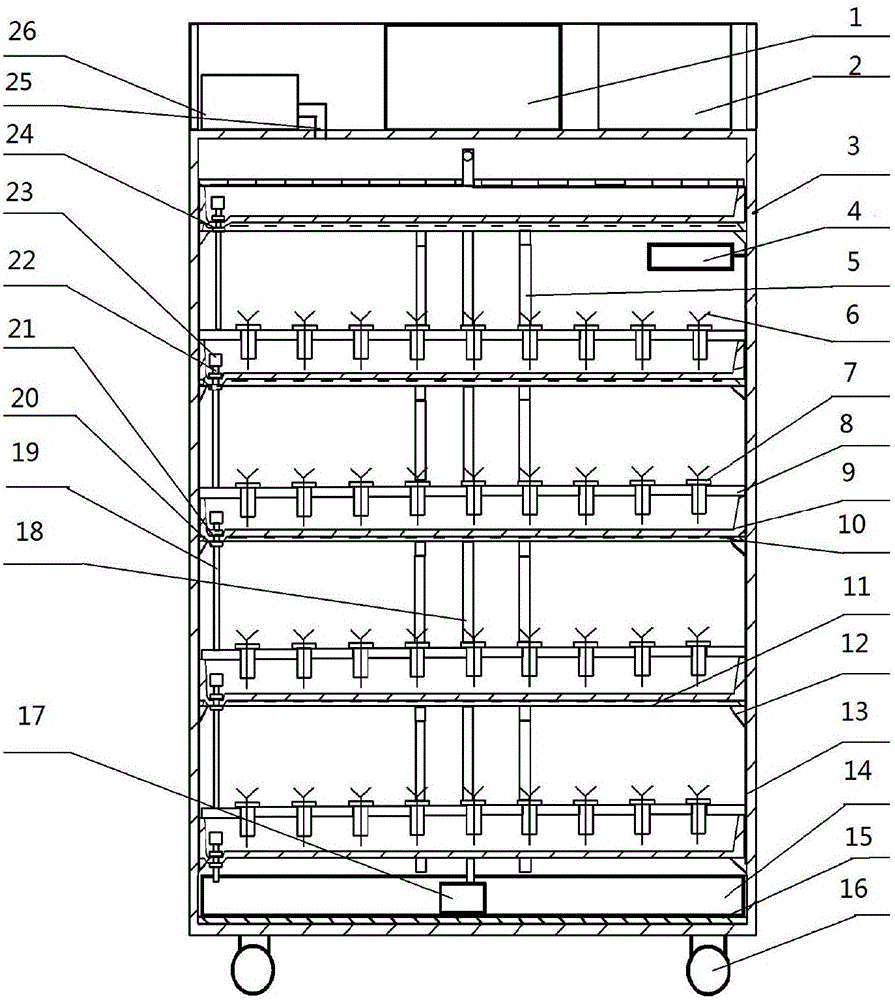

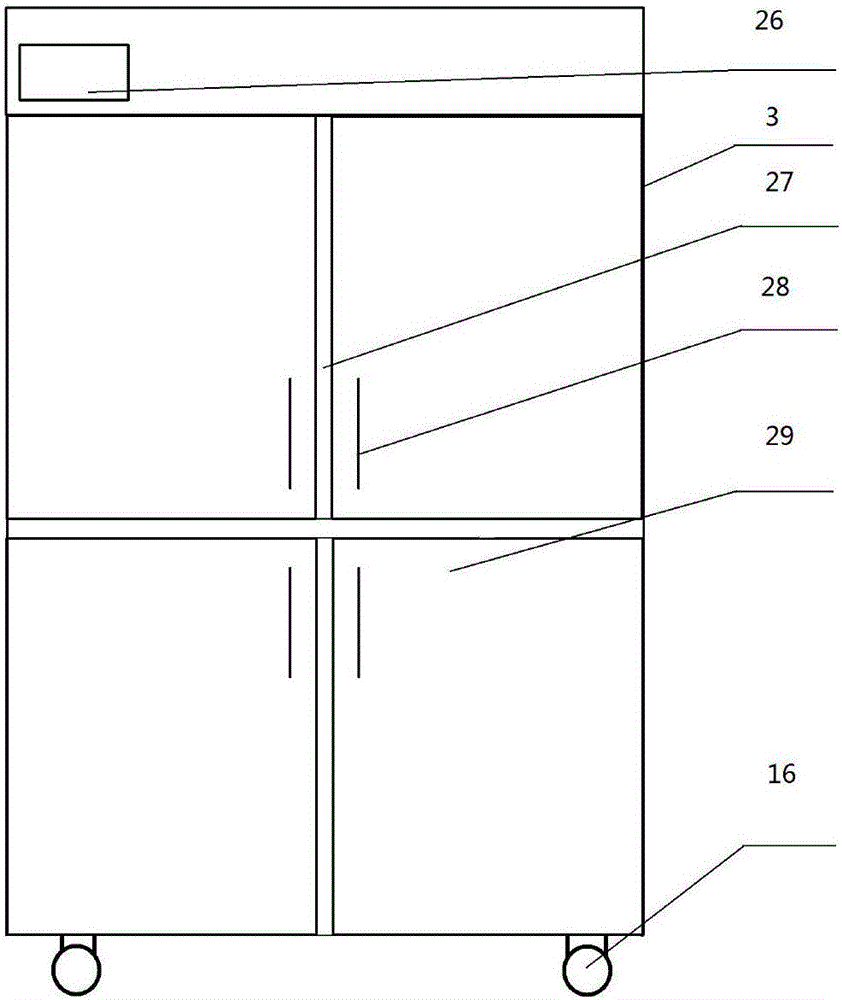

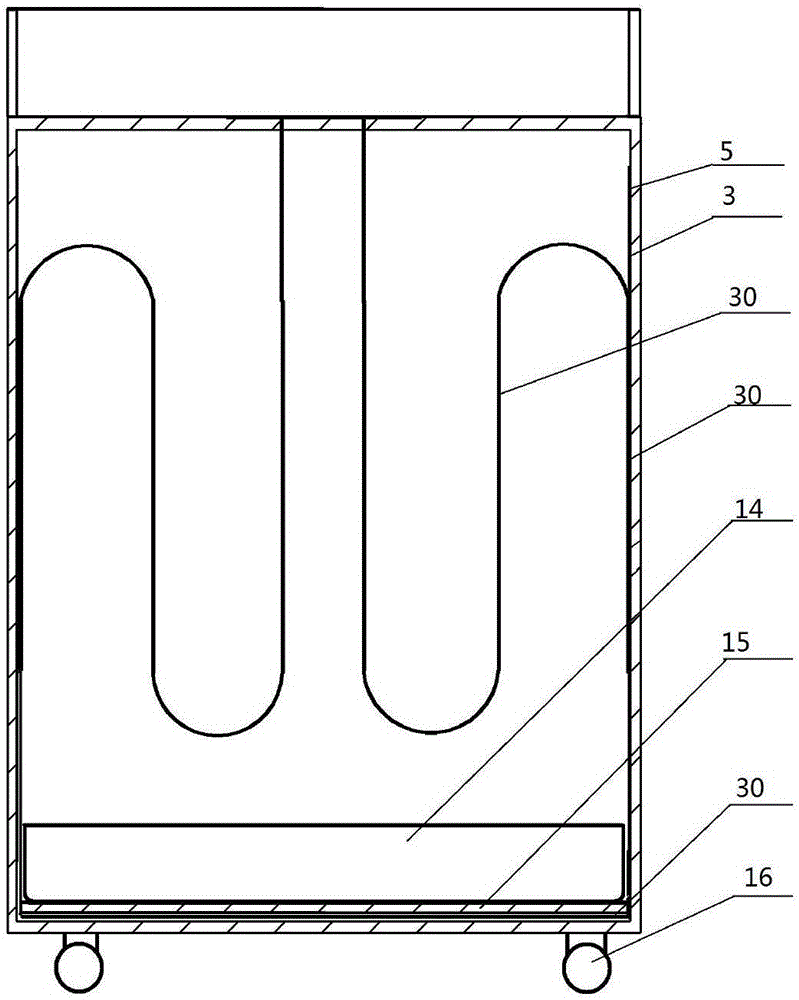

Vegetable cultivation machine

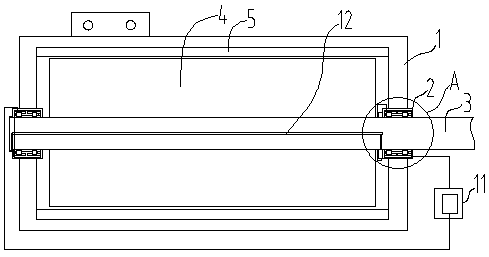

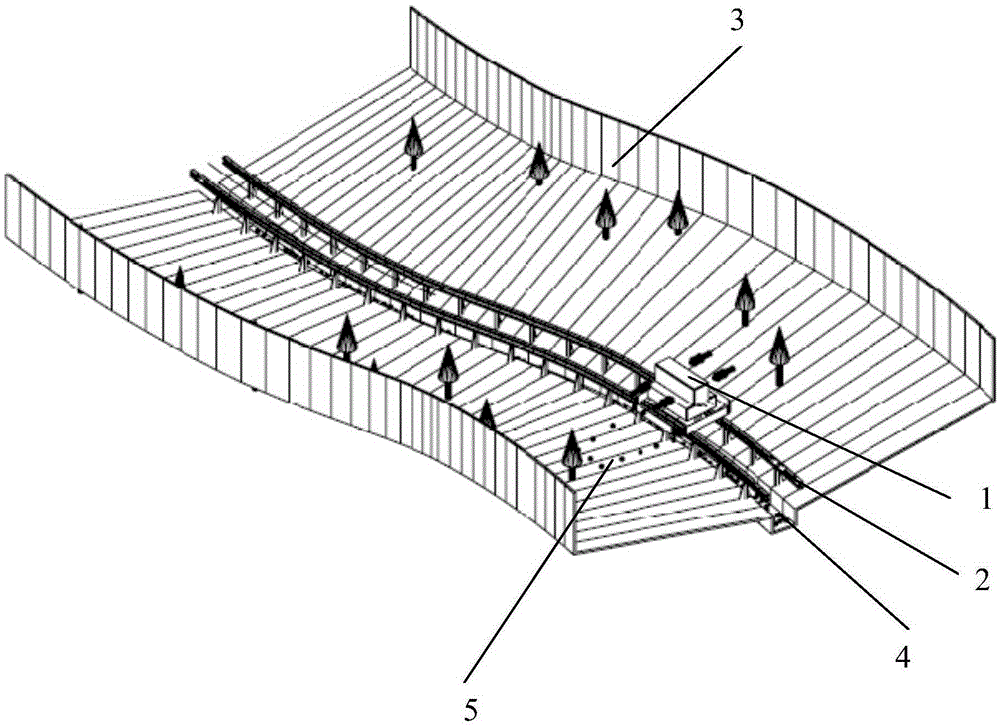

InactiveCN106376452AReliable cycleLight controllableSaving energy measuresAgriculture gas emission reductionTemperature controlControl system

The invention discloses a vegetable cultivation machine which comprises a heat-insulating box, wherein a plurality of cultivation trays are vertically arranged in the heat-insulating box through tray brackets; the vegetable cultivation machine is characterized by further comprising an environment control system; the environment control system comprises a nutrient solution circulating system, an air circulating system, a temperature control system and an illuminating system. The vegetable cultivation machine is energy-saving, has a simple structure, is capable of fully circulating the nutrient solution, is capable of controlling temperature, humidity and illumination and can supply sufficient nutrient solution, carbon dioxide and oxygen.

Owner:于葵 +2

Three-return-stroke powder heat conduction oil boiler

The invention discloses a three-return-stroke powder heat conduction oil boiler. The three-return-stroke powder heat conduction oil boiler comprises a circulating oil pump, a hearth, a burnout chamber, a convection tube bundle, tail heat exchange equipment, a combustor, a slag falling device, a lower header and an upper header, wherein the lower header is arranged at the bottom of a boiler body; the upper header is arranged at the top of the boiler body; the combustor is arranged at the front part, the top, the bottom or the side part of the hearth of the boiler; the boiler body has a full-film type water-cooled wall structure, and four main downcomers are arranged at four corners; the convection tube bundle is arranged in a convection tube bundle flue, the convection tube bundle flue is longitudinally arranged, and the height of the convection tube bundle flue is equal to that of the hearth; the upper and lower ends of the convection tube bundle, the main downcomers and a film type water-cooled wall are communicated with the upper header and the lower header respectively; the burnout chamber and the hearth are longitudinally arranged abreast in a back-to-back way, and the height of the burnout chamber is equal to that of the hearth; the hearth, the burnout chamber, the convection tube bundle flue and the tail heat exchange equipment are sequentially conducted in series; two-stage combustion-supporting and denitration secondary air is distributed in the hearth. The three-return-stroke powder heat conduction oil boiler has the characteristics of long flue gas flow, complete fuel combustion and high heat exchange efficiency.

Owner:HANGZHOU JUNENG BOILER

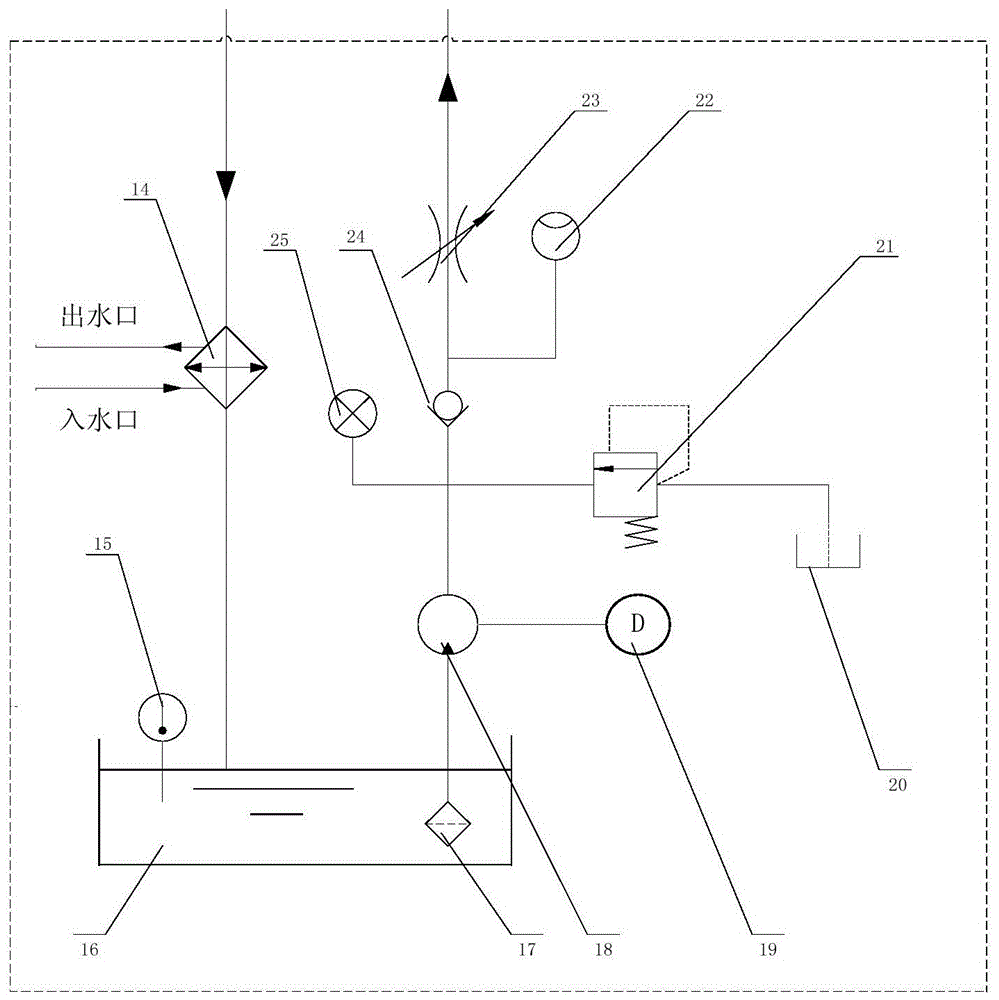

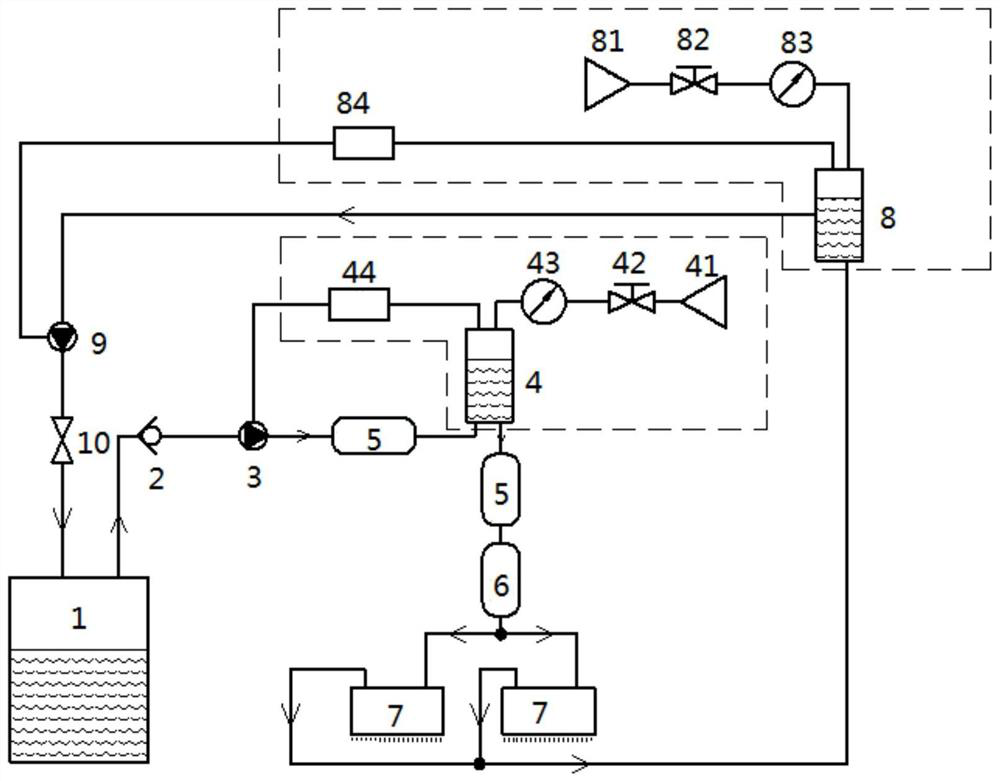

Self-balancing liquid supplementing and exhausting device for temperature control equipment

PendingCN111980910ARealize closed loopMake sure to inflatePositive displacement pump componentsLiquid fuel engine componentsTemperature controlProcess engineering

The invention discloses a self-balancing liquid supplementing and exhausting device for temperature control equipment. The self-balancing liquid supplementing and exhausting device comprises a liquidpump, a liquid outlet pipeline, a working pipeline and a liquid return pipeline, and further comprises a heater barrel and a liquid inlet pipeline, and further comprises a liquid supplementing water tank, a liquid supplementing pipe and an exhausting pipe. The self-balancing liquid supplementing and exhausting device can solve the problem that when a liquid pumping pump is used for pumping liquid,air in the pump and pipelines of the pump must be manually exhausted into the pump every time the pump is started.

Owner:合肥亦威科技有限公司

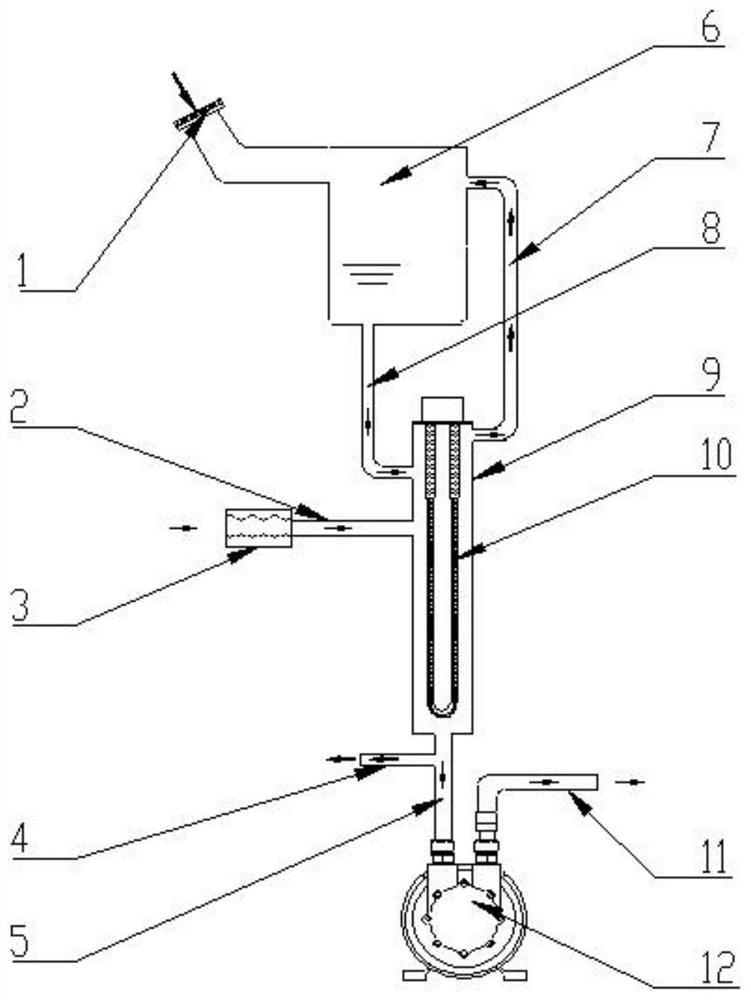

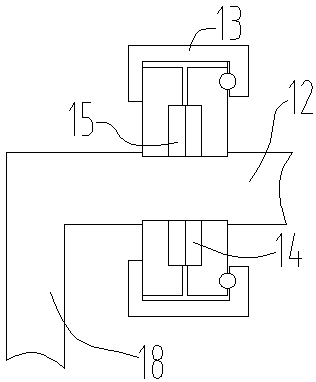

Lubrication system of handheld air-cooled four-stroke gasoline engine and gasoline engine

PendingCN109798163ASimple structureLubricating oil forming cycle separation is reliableMachines/enginesPressure lubricationLubricationReturn channel

The invention relates to a lubrication system of a handheld air-cooled four-stroke gasoline engine and a gasoline engine. The lubrication system comprises a cylinder block, a crankshaft connecting rodgroup, a piston, a crankcase formed by a front box body and a rear box body and a cylinder cover; the lubrication system furhter comprises a crankshaft chamber and an oil storage chamber which communicate with each other, an oil feeding channel and an oil returning channel which form a circulation and are provided with a one-way valve; through the change of pressure in a rotary crank chamber of the crankshaft, lubricating oil mist lubricates all parts in a valve chamber, a tappet chamber, a cam chamber and the crank chamber. a first-stage oil-gas separation channel and a second-stage exhaustchannel are arranged to discharge the burnt waste gas which enters the crank chamber from the gap between the piston and the cylinder body out of the crankcase; The scheme provided by the invention has the beneficial effects of smooth circulation of lubricating oil, reliable separation of the oil-gas separation device, effective control of waste gas timing, unidirectional discharge, stable operation of products at any angle, etc.

Owner:SHANDONG HUASHENG PESTICIDE APPL MACHINERY CO LTD

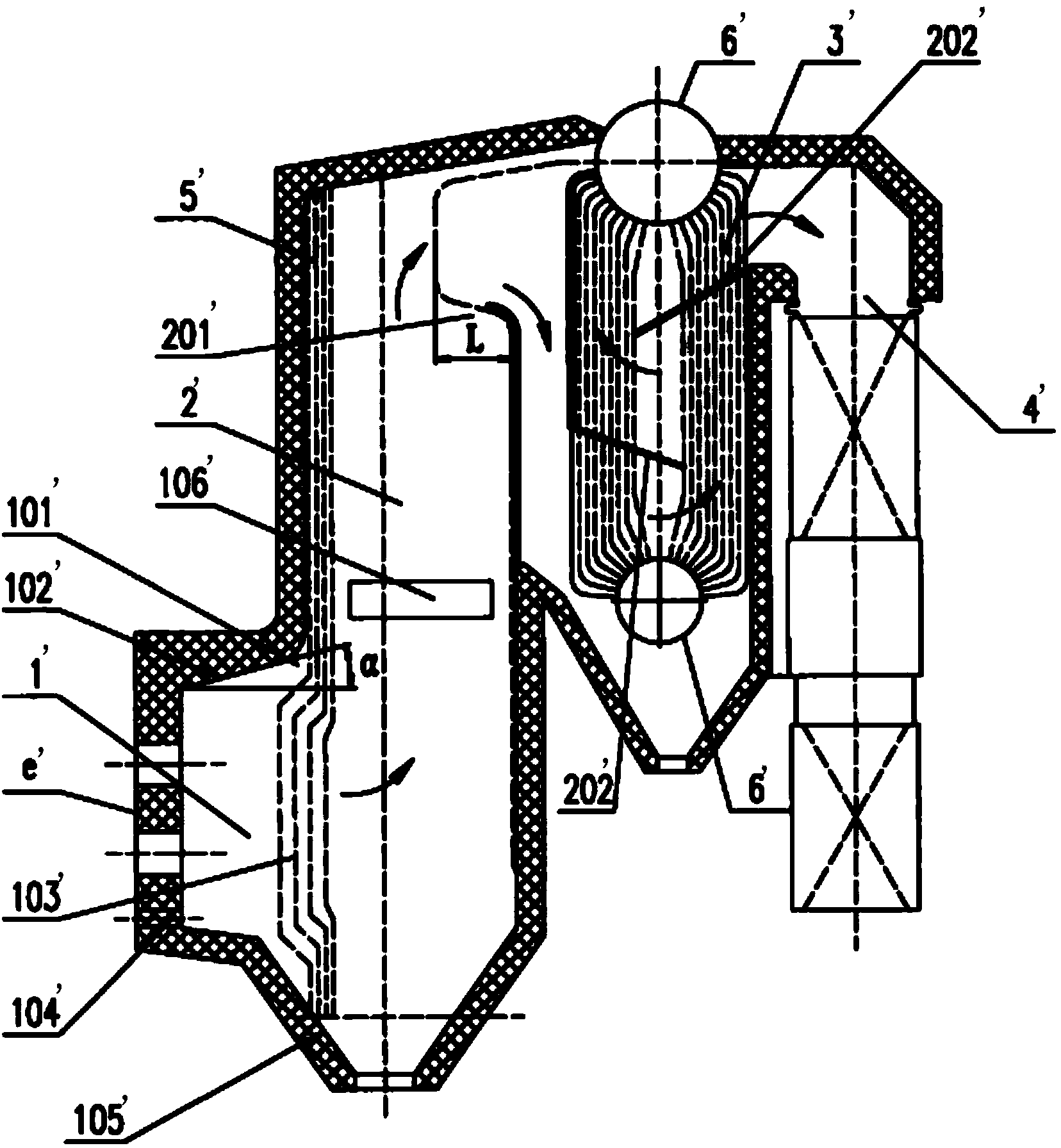

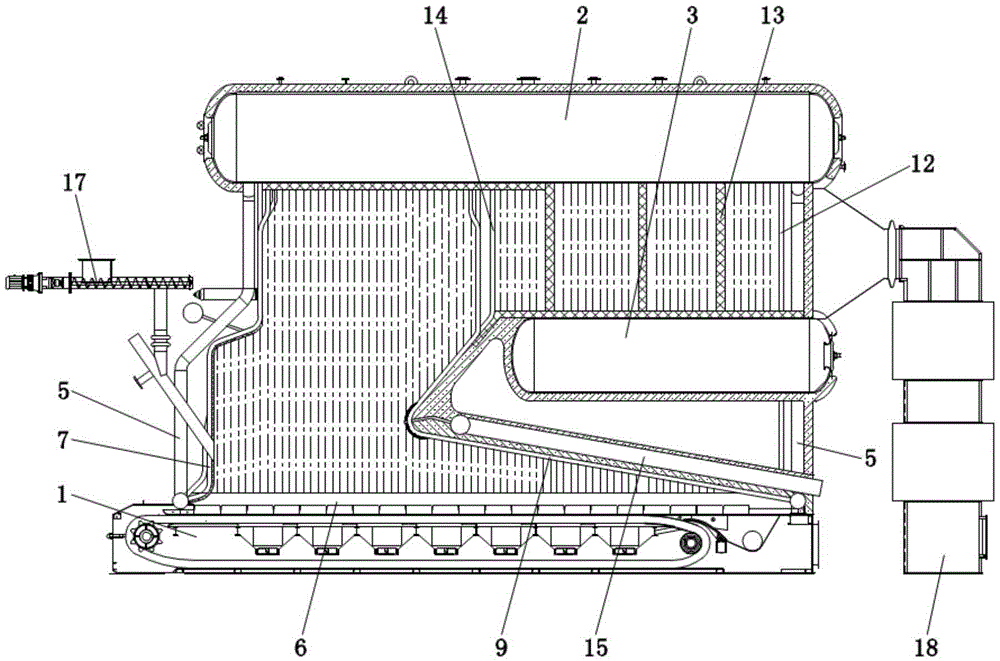

Vertical type modular coal water slurry corner tube boiler

InactiveCN103134036ACompact structureOptimize layoutIndirect carbon-dioxide mitigationSteam boilersAir preheaterCoal water

The invention discloses a vertical type modular coal water slurry corner tube boiler. The vertical type modular coal water slurry corner tube boiler comprises a boiler body, a hearth, a combustor, a combustion stabilizing chamber, a dry bottom hopper, an air preheater, a coal economizer, a convection tube beam, an upper collecting tank, a top collecting tank, a boiler barrel and a lower collecting tank. The boiler body comprises 4 down pipes arranged at four corners and a membrane water wall. Two ends of each down pipe and two ends of the membrane water wall are respectively communicated with the upper collecting tank and the lower collecting tank. The convection tube beam is arranged on outer side of the membrane water wall, the top is communicated with a smoke outlet of the hearth, and the bottom is communicated with the bottom of the air preheater. The dry bottom hopper is arranged at the bottom of the boiler body. The boiler body is divided into the boiler barrel, the dry bottom hopper, the convection tube beam and the membrane water wall to be manufactured and installed. The vertical type modular coal water slurry corner tube boiler has the advantages of being compact in integral structure, simple in appearance arrangement, small in occupied area, low in steel consumption, large in boiler water circulating differential pressure, safe and reliable in water circulation, quick and simple in manufacture and installation, reliable in boiler operation, simple and convenient to maintain and the like.

Owner:HANGZHOU JUNENG BOILER

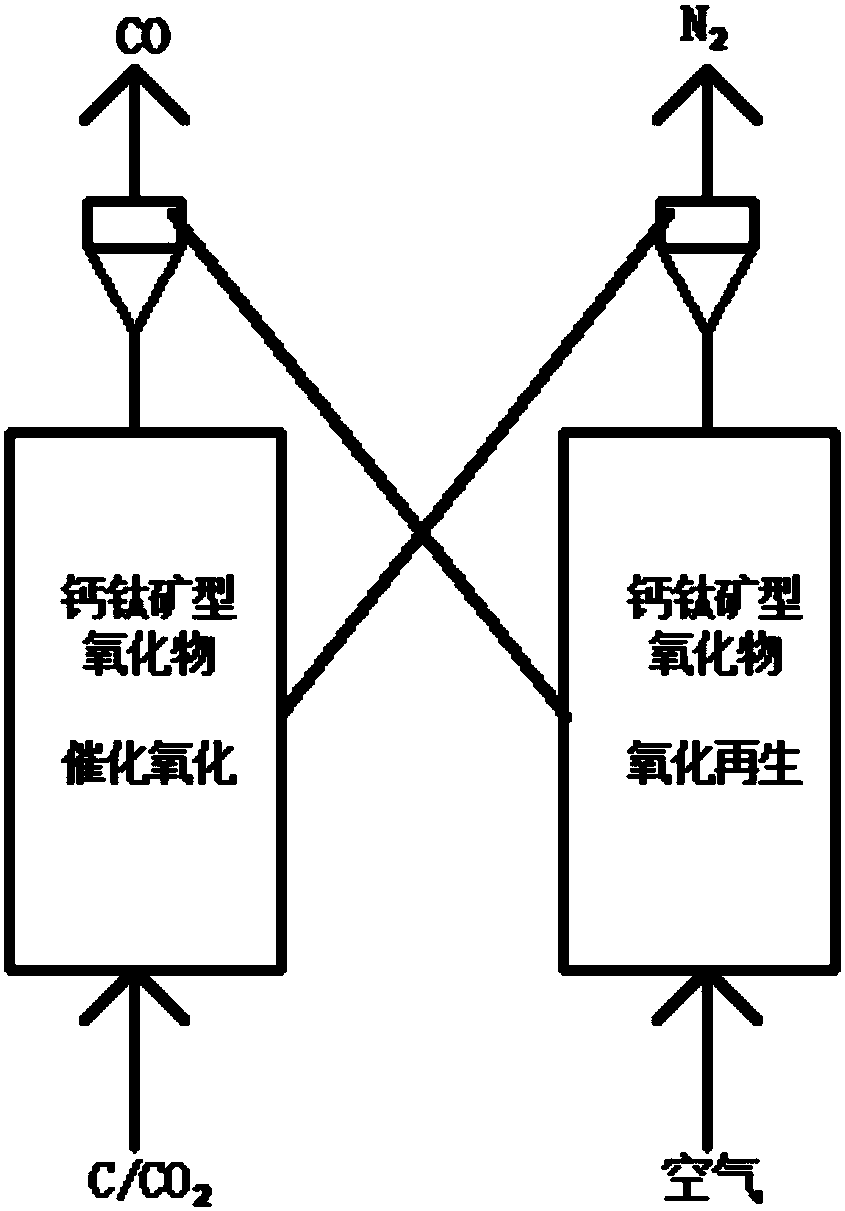

Method for catalyzing coke-carbon dioxide gasification based on chemical-looping principles

InactiveCN107892948ALow volatile contentGuaranteed purityGasification processes detailsChemical recyclingCatalytic oxidationOxygen

The invention specifically discloses a method for catalyzing coke-carbon dioxide gasification based on chemical-looping principles, belonging to the field of coal gasification. The method comprises the following steps: conveying a catalyst into a gasification furnace for contact with a raw coke material so as to realize coke-carbon dioxide gasification, wherein the catalyst releases oxygen duringgasification; conveying the catalyst having released oxygen into a calciner for calcining so as to reduce the structure of the catalyst; and conveying the catalyst into the gasification furnace for participation in coke-carbon dioxide gasification again. The method can realize cyclic utilization of the catalyst during catalytic oxidation and calcining reduction, improves the recycling rate of thecatalyst and has the advantages of high recycling rate, easiness, reliability, convenience in implementation, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

Rolling bearing system of automobile motor

InactiveCN108123568AImprove the lubrication effectImprove cooling effectSupports/enclosures/casingsRolling-element bearingMotor shaft

The invention discloses a rolling bearing system of an automobile motor. The system comprises a housing of the motor, bearing components and a motor shaft provided with a first oil path along an axisdirection. The two opposite surfaces of the housing are provided with the bearing components, the motor shaft and the bearing components are in fitting installation to form a support for the motor shaft, and upper parts of the two bearing components are provided with oil inlet holes. The bottom of one bearing component is provided with an oil groove connected to an oil pool, and the oil inlet holeof the upper part is connected to a liquid out port of the first oil path. The oil inlet hole of the upper part of the other bearing component is connected to the oil pool, the lower part of the bearing component is also provided with an oil groove which is connected to a liquid in port of the first oil path, and an oil liquid loop is formed between the two bearings of the motor through the firstoil path in the motor shaft. The invention aims to provide the rolling bearing system of the automobile motor with the prolongation of the maintenance period of the motor bearings and the increase ofthe reliability of the bearings.

Owner:李兴强

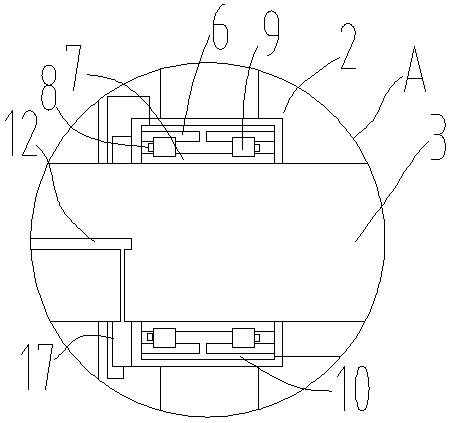

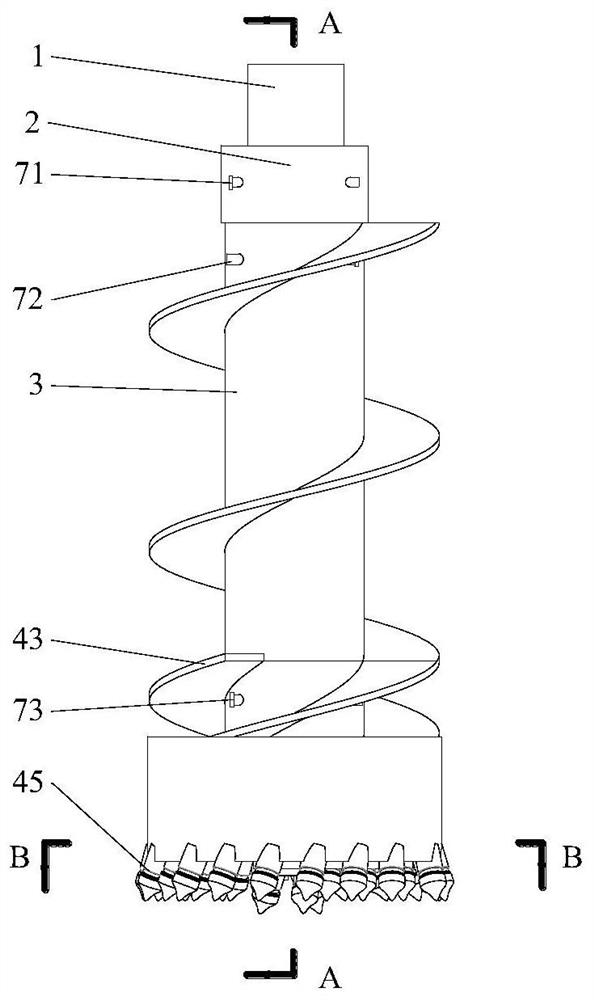

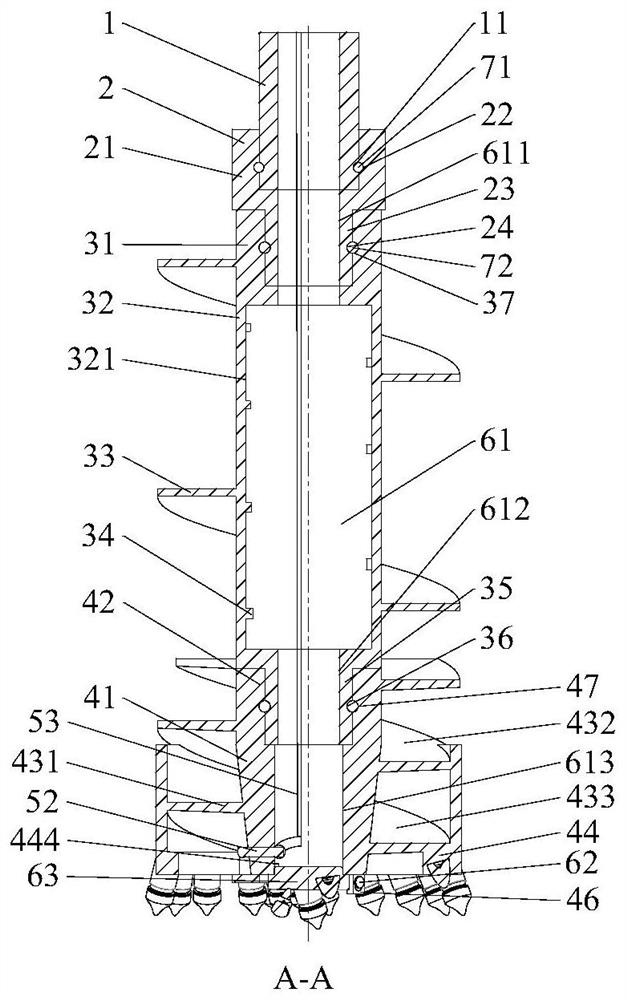

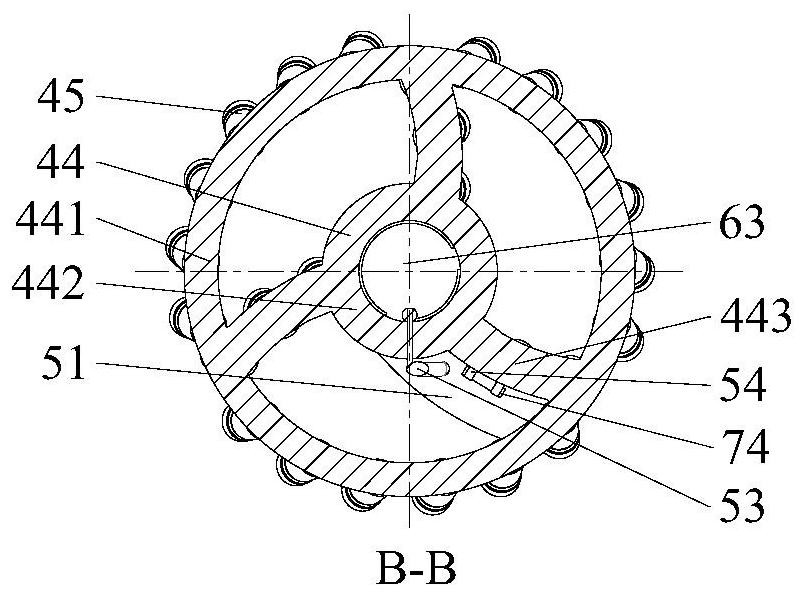

Continuous drilling and cyclic pouring integrated piling tool

ActiveCN112282658AIncreased piling drilling efficiencySimple structureDrill bitsDrilling rodsStructural engineeringMechanical engineering

The invention belongs to the field of constructional engineering and mechanical engineering, and particularly relates to a continuous drilling and cyclic pouring integrated piling tool. According to the technical scheme, the continuous drilling and cyclic pouring integrated piling tool comprises a power connecting piece, a circulating device, a drill bit component, a bottom cleaning mechanism anda pouring mechanism, wherein the circulating device comprises a circulating drilling barrel and a spiral piece, both ends of the circulating drilling barrel are respectively connected with the power connecting piece and the drill bit component or the circulating drilling barrel, and the spiral piece is connected with the circulating drilling barrel; the drill bit component comprises a drill bit base, a drill bit seat and a drill bit, the drill bit seat is connected with the drill bit base, and the drill bit is connected with the drill bit seat; the bottom cleaning mechanism comprises a connecting rod and bottom cleaning blades; and the pouring mechanism comprises a pouring channel and a control piece. The invention provides a novel continuous drilling and cyclic pouring integrated piling tool, and the piling drilling and cyclic chip removal and continuous pouring efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Vertical type coal dust corner tube boiler

InactiveCN103062748AFull reaction combustionImprove sealingSteam boilersSmall footprintTubular membrane

The invention discloses a vertical type coal dust corner tube boiler which comprises a burner, a boiler furnace, a high temperature air preheater, a coal economizer, a low temperature air preheater convection tube bundle, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of a boiler body, and the upper collecting box and the top collecting box are arranged at the top of the boiler body and are communicated through a vapor communicating pipe. The vertical type coal dust corner tube boiler is characterized in that the burner is arranged at the top of the boiler body, the boiler body is of a vertical type tubular membrane type water-cooled wall structure, four down pipes are arranged at four corners, and the down pipes and two ends of the membrane type water-cooled wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged on the outer side of the membrane type water-cooled wall, the bottom of the convection tube bundle is communicated with a hearth smoke outlet, and the top of the convection tube bundle is communicated with the high temperature air preheater. The vertical type coal dust corner tube boiler has the advantages that an integral structure is compact, the appearance is arranged simply, an occupied area is small, steel consumption is small, water circulating differential pressure of the boiler is large, and water circulation is safe and reliable, and the like.

Owner:HANGZHOU JUNENG BOILER

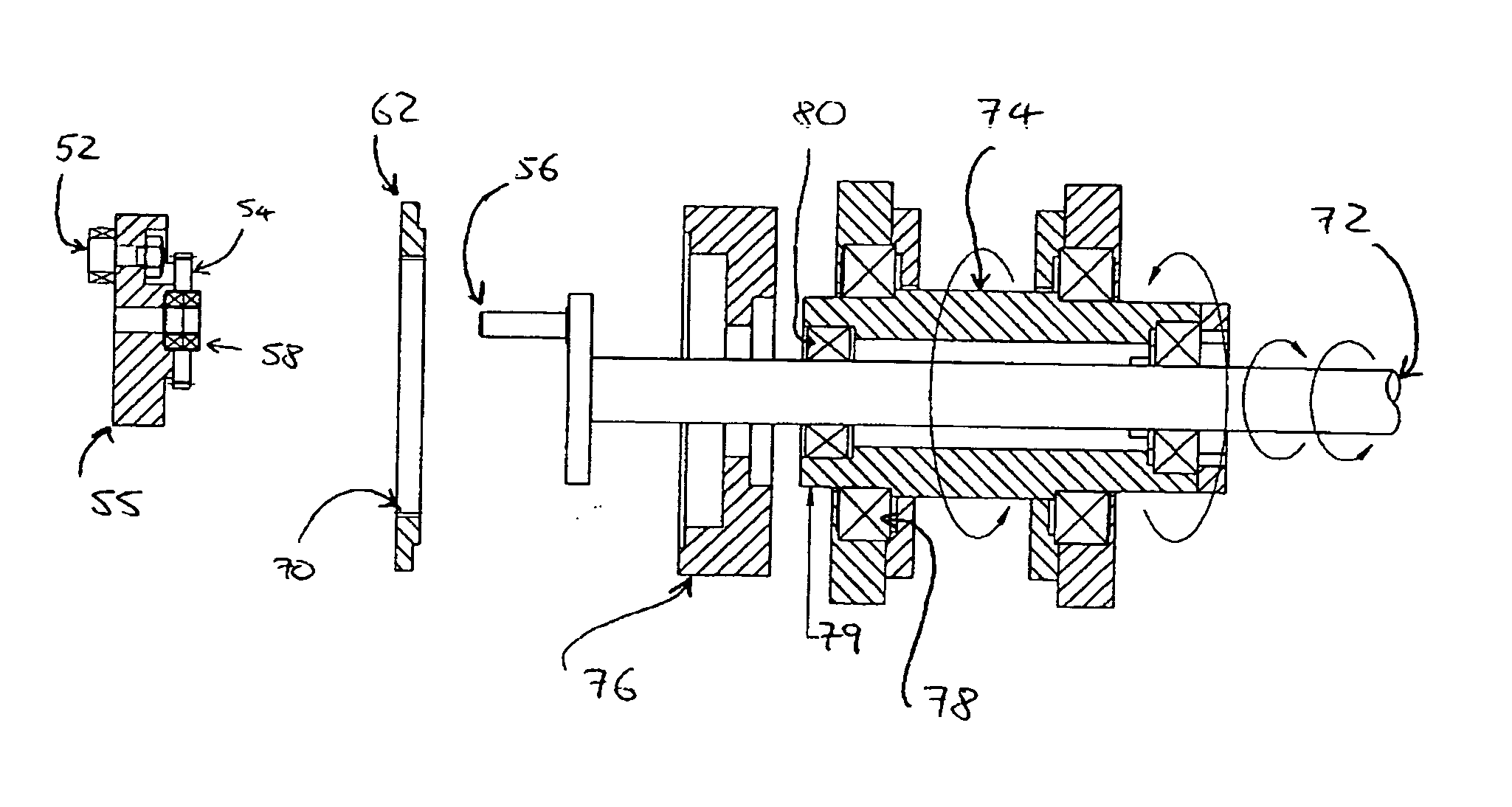

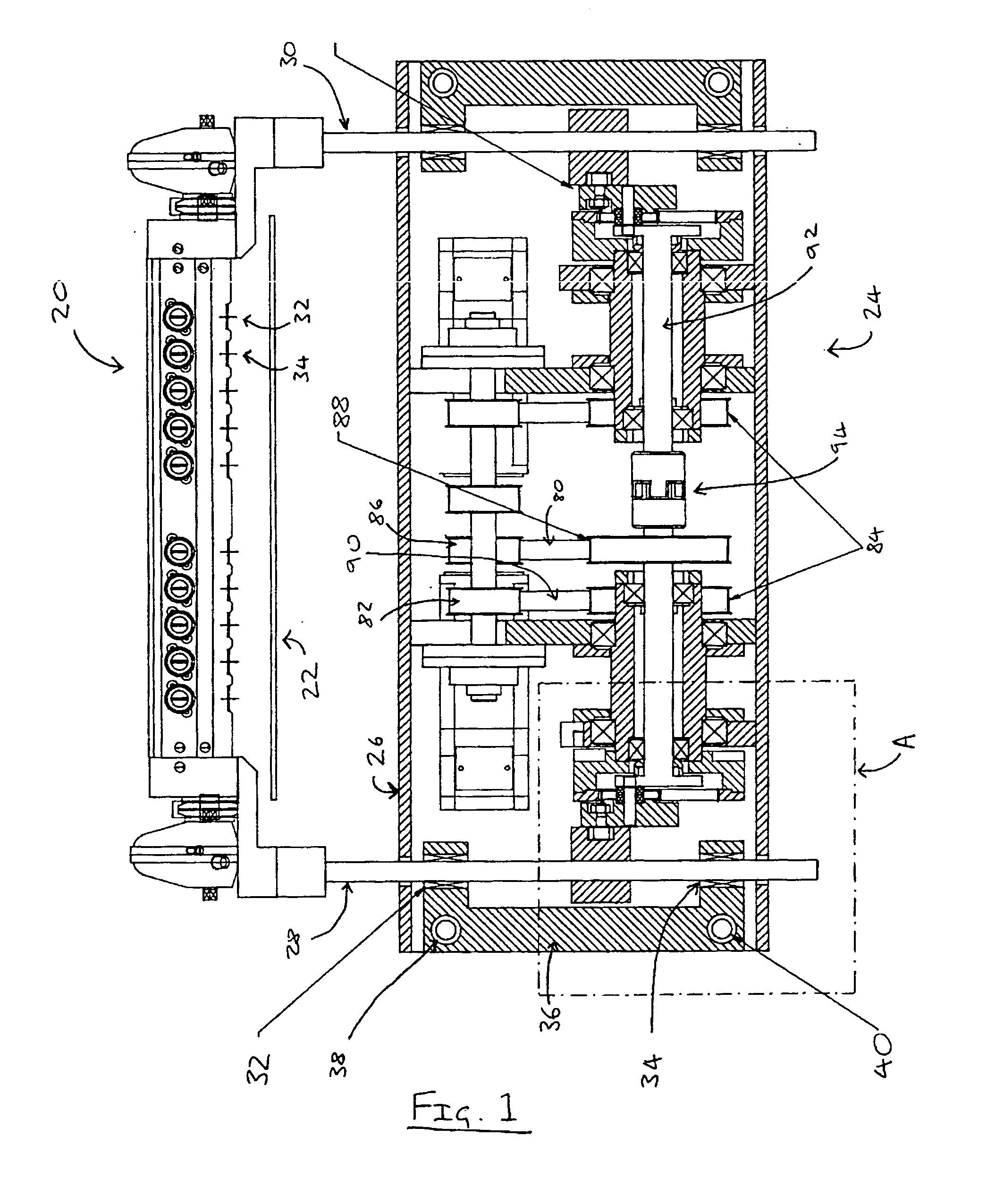

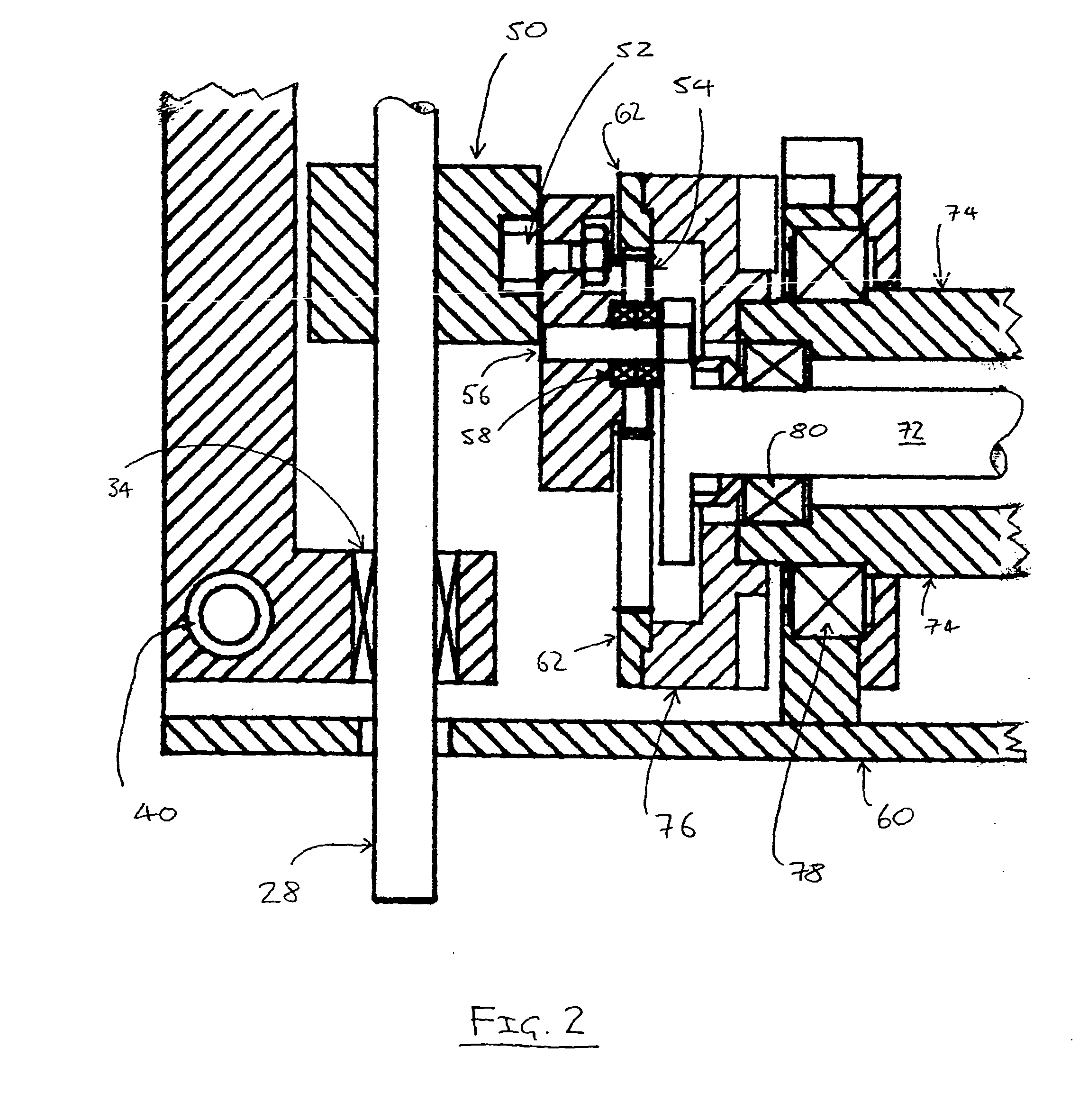

Movement output apparatus

The present invention provides a movement output apparatus for controllably moving a movement output means in at least two spatial dimensions, the apparatus including: a cog means with a first diameter; a ring with a track formed on an inner surface of the ring, the track having a second diameter which is larger than the first diameter; wherein: the cog means is rotatable by first driving means; the ring is rotatable by second driving means; the cog means is arranged to move, in use, along the track; and the movement output means is attached to the cog means, whereby, in use, movement of the cog means effects movement of the movement output means, and the movement of the movement output means is controllable by control of the first and second driving means to produce substantially linear movement of the movement output means to produce substantially linear movement of the movement output means.

Owner:WYMBS ENG

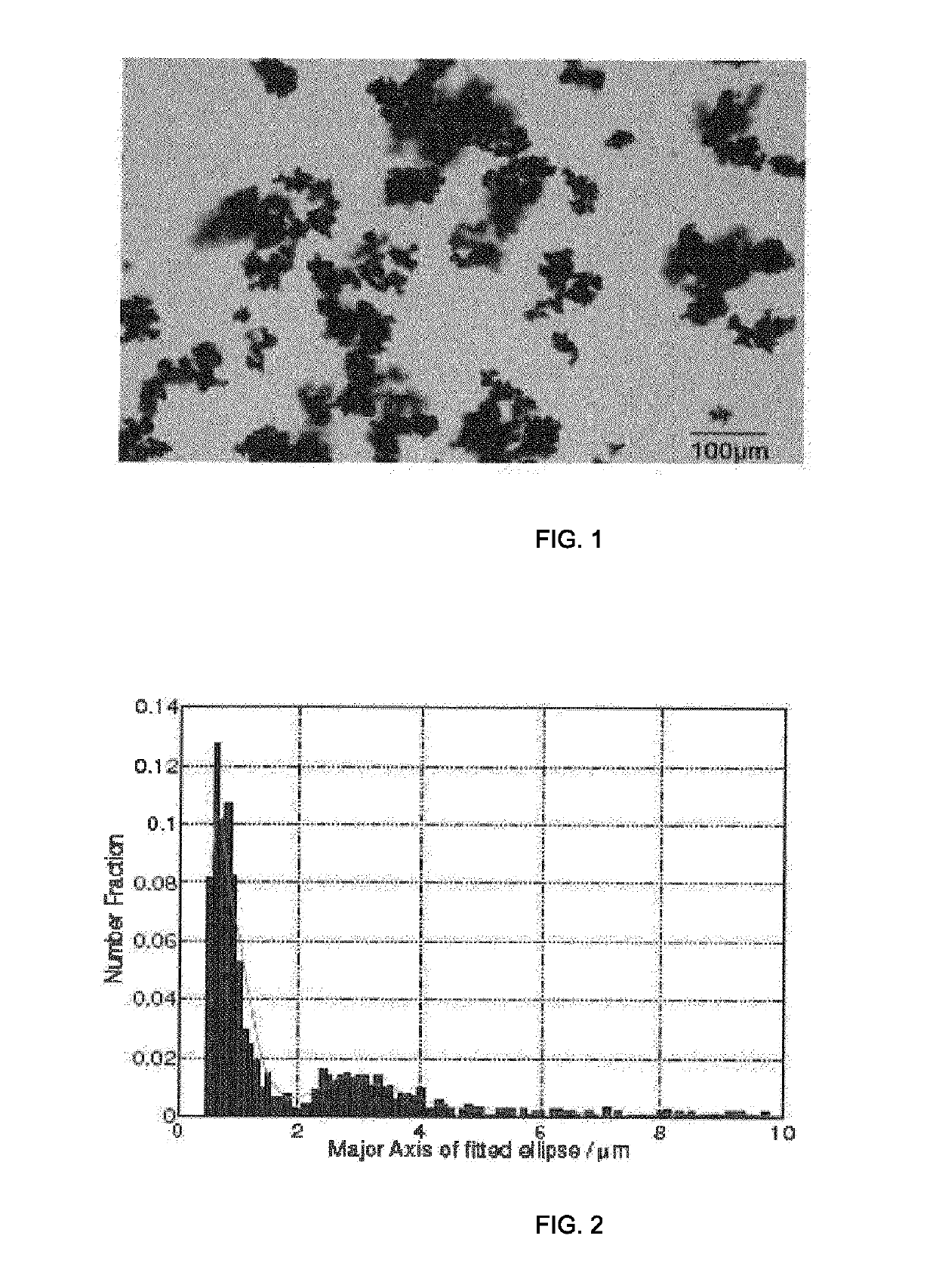

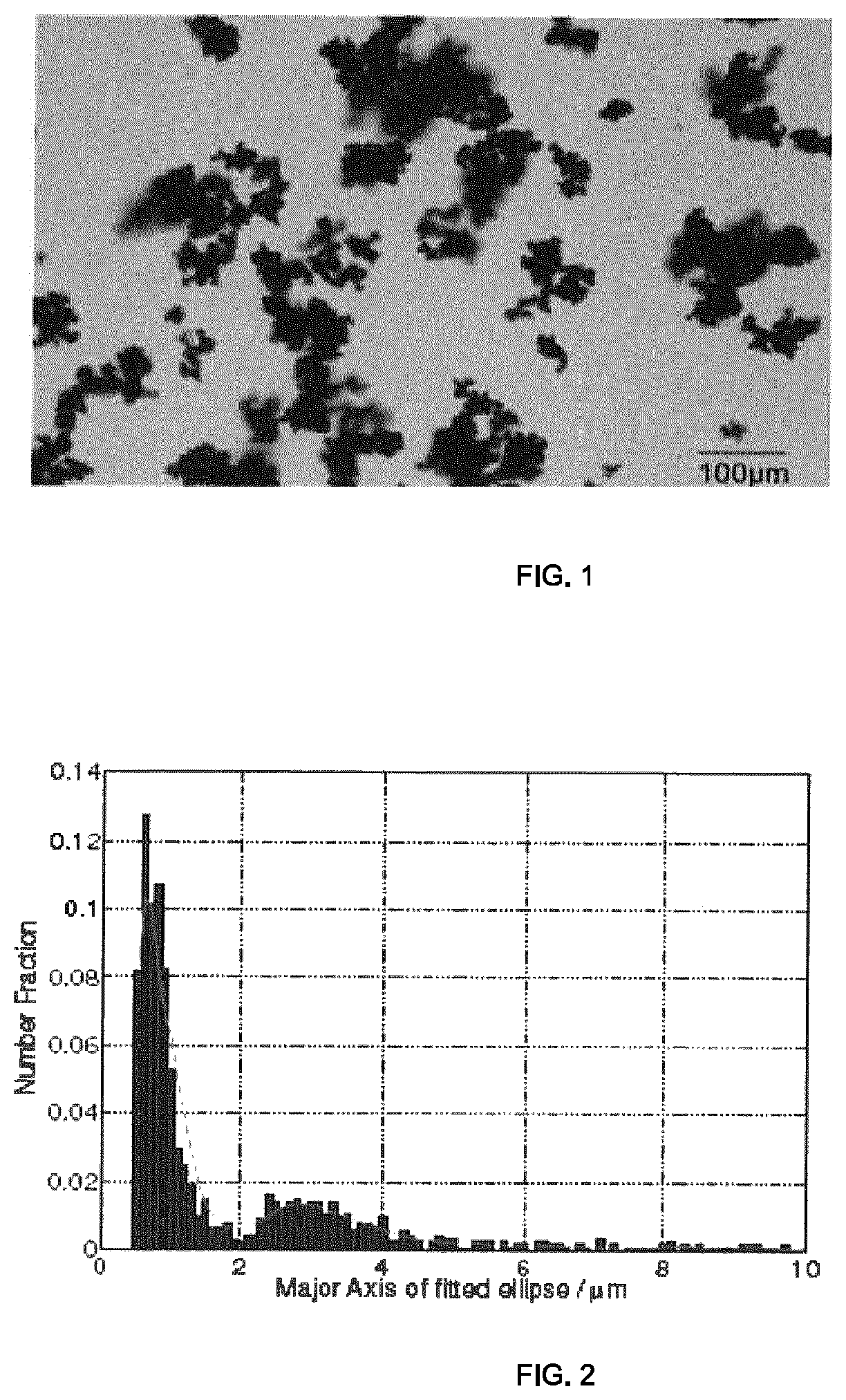

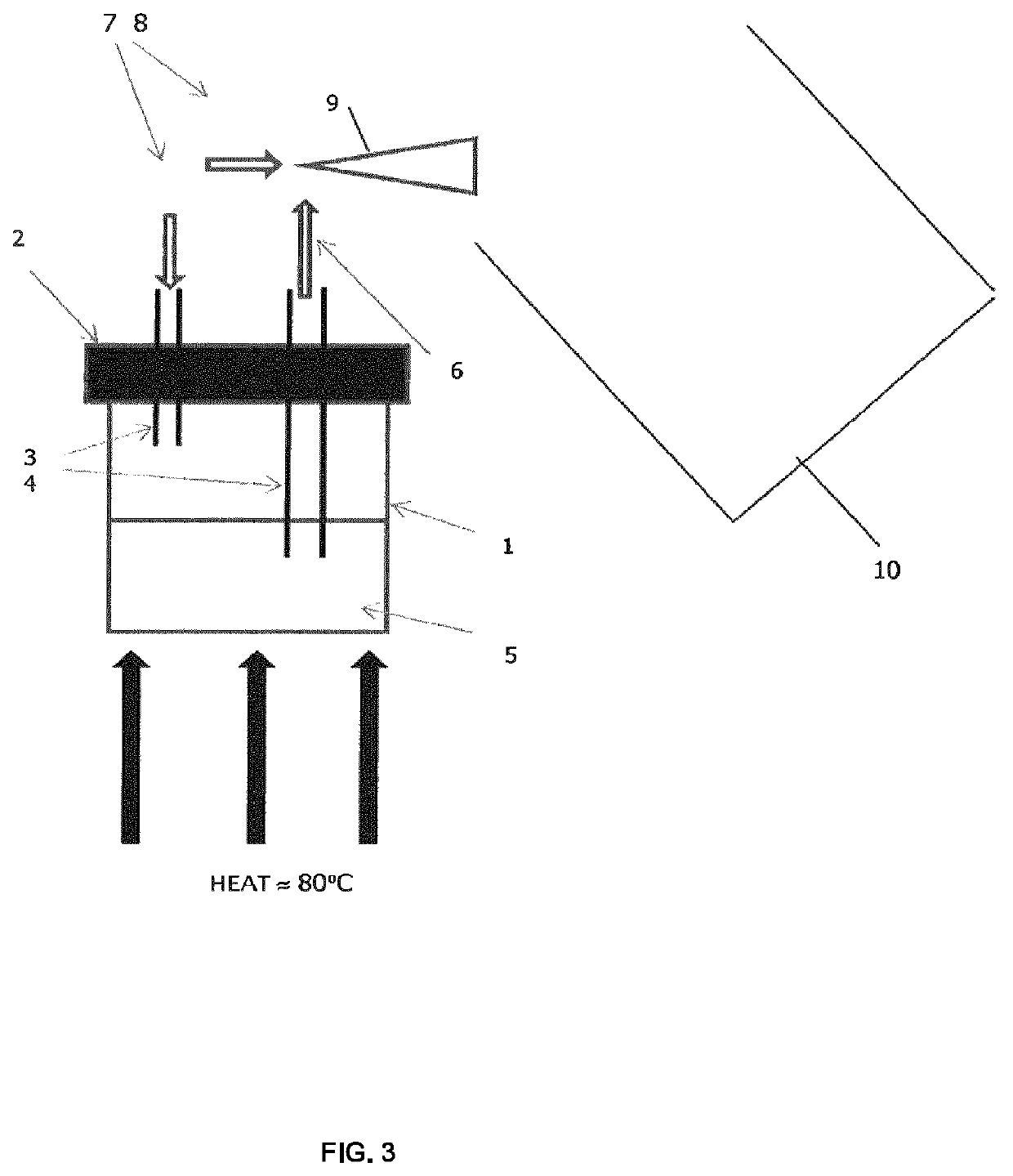

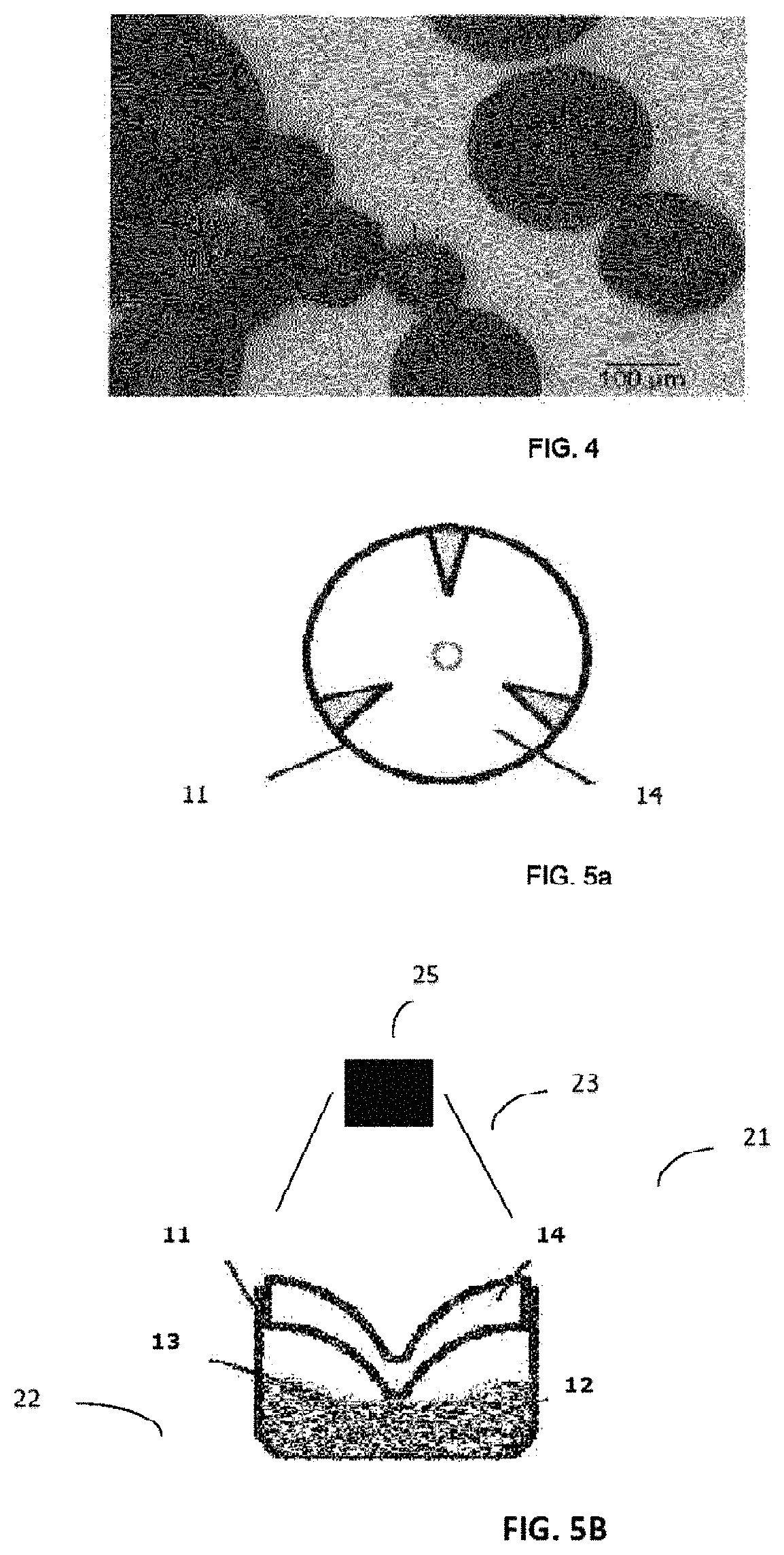

Explosive composition for use in telescopically expanding non-lethal training ammunition

ActiveUS20190135712A1Less aggressiveReduces standard deviationTraining ammunitionNon-explosive desensitisers/phlegmatisersEngineeringEnergetic material

An explosive composition for use in telescopically expanding non-lethal training ammunition comprises tetrazene and paraffin wax. The explosive composition can be used as a primer and / or as a source of energetic material in a telescopically expanding non-lethal training cartridge; it can be used to propel a projectile from a telescopically expanding non-lethal training cartridge; and / or it can be used to expand telescopically a non-lethal training cartridge within a host gun.

Owner:UTM IP

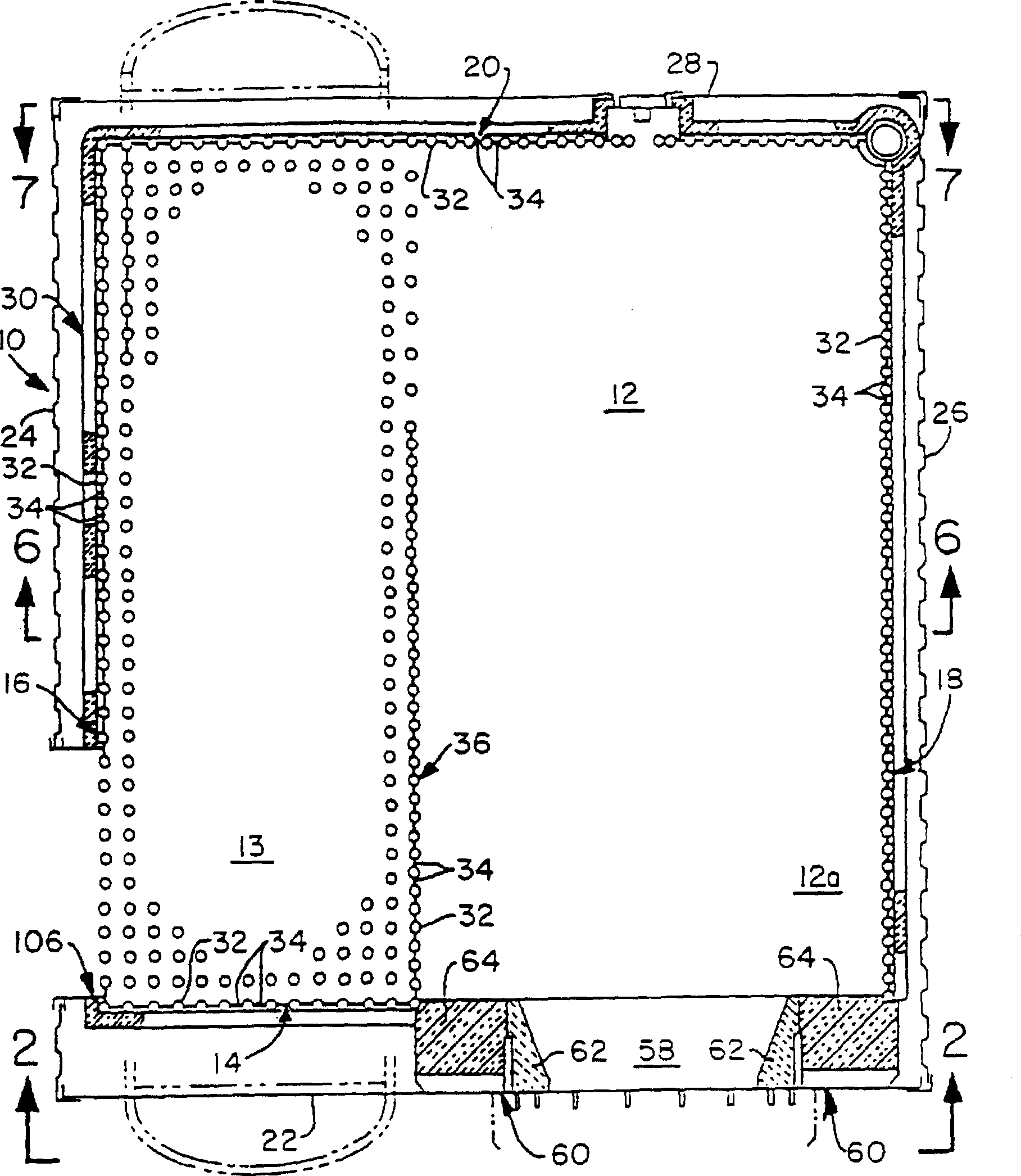

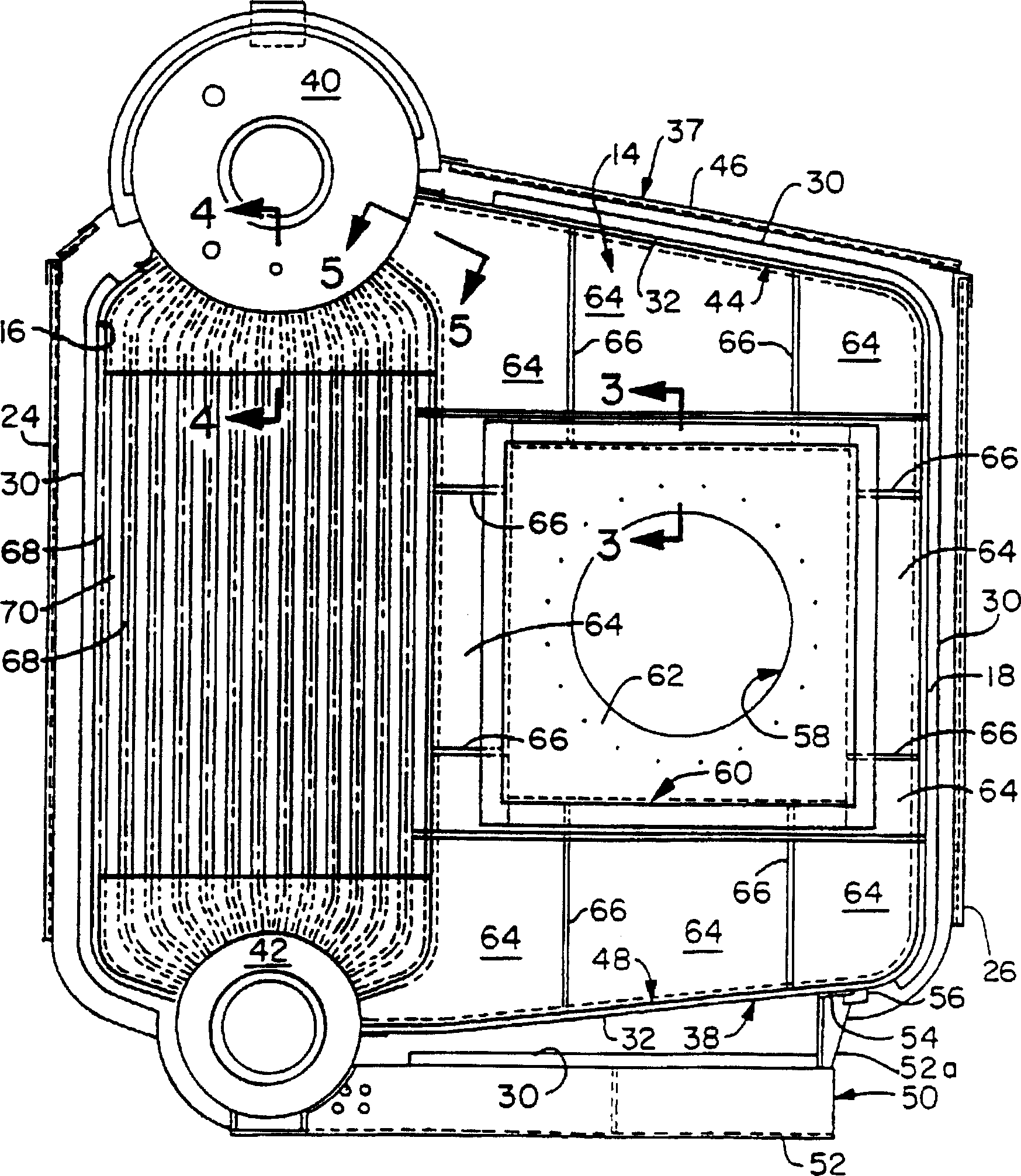

Package boiler of unitary construction

InactiveCN1127637CMeet special needsEven heat distributionWater-tube boilersSteam boilers componentsFiberRefractory

A package boiler (10) of unitary construction embodying based on the particular pressure and temperature conditions required thereof a predetermined standard profile selected from a plurality of standard profiles collectively capable of providing within a range of design pressures up to 1050 psig and a range of design superheater outlet temperatures up to 750 degrees F steam production within a range of 20,000 to 180,000 pounds per hour, and embodying based on the nature of the fuel to be burned therewithin a front wall (14, 14') of predetermined construction selected from front walls (14) of rigidized ceramic fiber for use when the fuel being burned therewithin is light oil and natural gas, front walls (14) of heavy castable refractory for use when the fuel being burned therewithin is heavy oil and other special fuels, and front walls (14') that are fully water-cooled.

Owner:ABB ALSTOM POWER INC

Automatic collection and loading device and collection method for amusement balls

The invention discloses an automatic collecting and filling device of ball projectiles for recreation and a collecting method of the automatic collecting and filling device. The automatic collecting and filling device comprises a track and inclined ground, wherein the track is mounted on a ball projectile vehicle body and allows the ball projectile vehicle body to move thereon, the inclined ground is arranged below a shooting range of the ball projectiles, one or more ball projectile return grooves are formed in the middle of the inclined ground, a ball projectile conveying belt for conveying the ball projectiles in the ball projectile return groove to a centralizing point is disposed at the tail end of each ball projectile return groove, a collector for collecting the ball projectiles on the ball projectile conveying belt in a centralized manner is mounted at the other end of the ball projectile conveying belt, and a ball projectile lifting device for lifting the ball projectiles inside the collector to a ball storage cabin in a centralized manner is connected to the bottom end of the collector.

Owner:北京万达文旅规划设计院有限公司

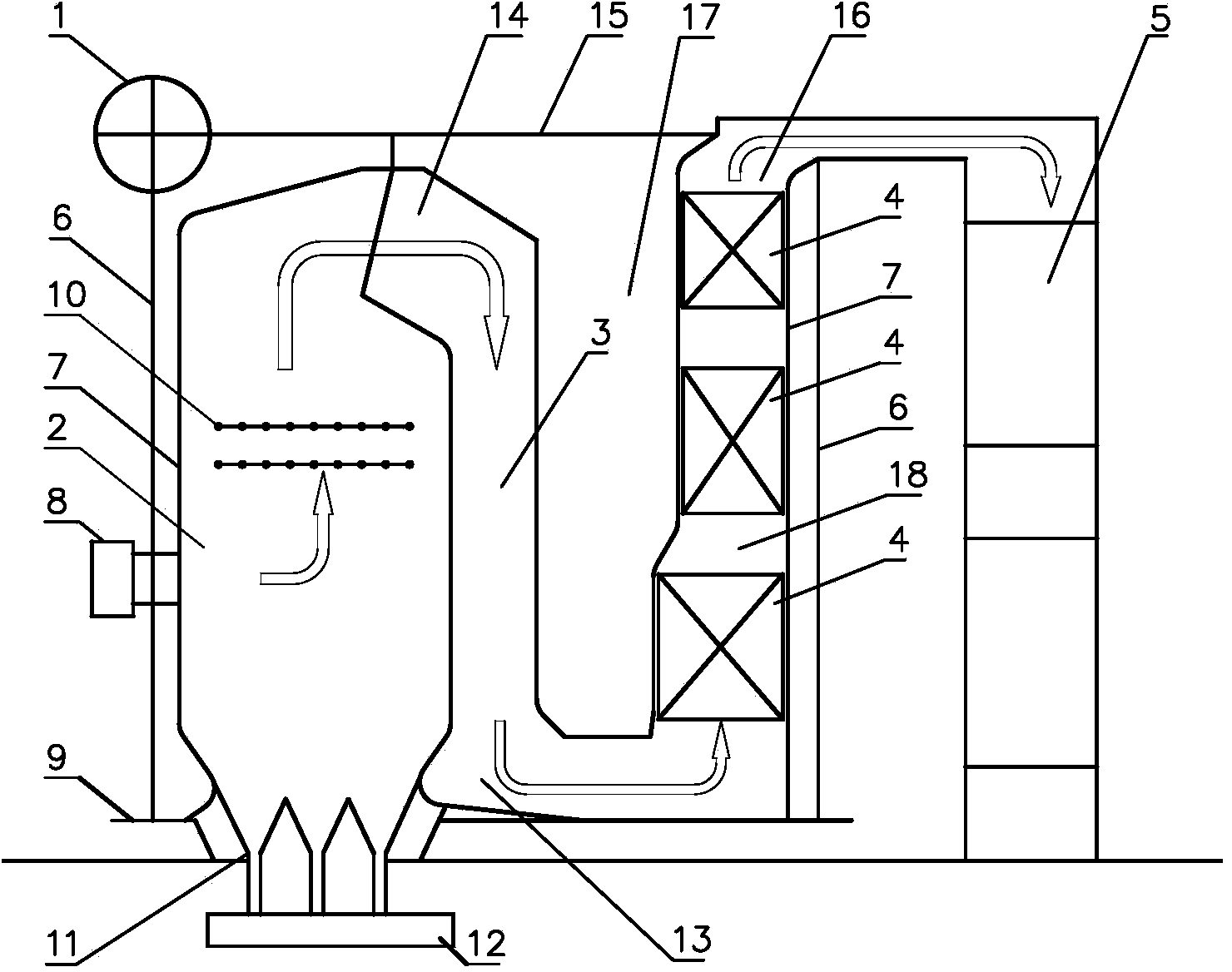

Biomass full-film type wall boiler

InactiveCN105605545ALose weightImprove air tightnessBoiler drums/headersWater-tube boilersNitrogen oxidesHearth

The invention discloses a biomass full-film type wall boiler. Front-film type walls, two-side-film type walls and rear-arch-film type walls are communicated between a corresponding lower collection box and an upper boiler cylinder of a boiler body of the biomass full-film type wall boiler to form a hearth with a fire grate in an enclosing mode, and the lower collection boxes are communicated with the rear-film type walls and the two-side-film type walls to form a flue with the upper boiler cylinder and a lower boiler cylinder in an enclosing mode. The hearth is designed to be of a full-film type wall structure, the weight of the boiler is reduced, air impermeability of the hearth is increased, the heating area is enlarged, it is beneficial to lower the temperature of the hearth, and generation of nitrogen oxide is inhibited; on the basis of the mentioned structure, the film type wall structure is also adopted for the flue, the heating area is enlarged, it is beneficial to lower the temperature of smoke discharged by the flue, the air leakage rate is reduced, and heating efficiency of the boiler is improved.

Owner:广州迪森热能设备有限公司

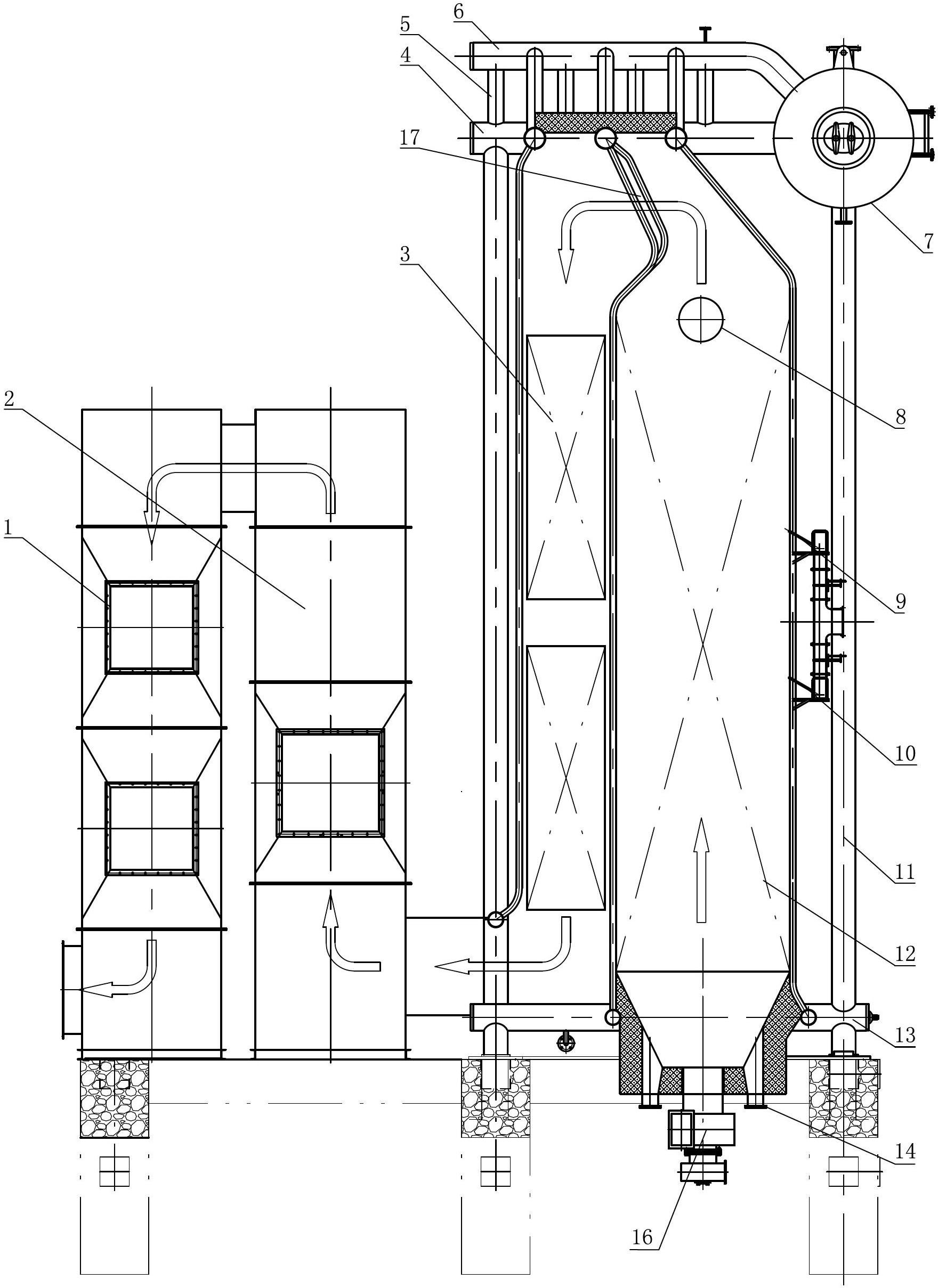

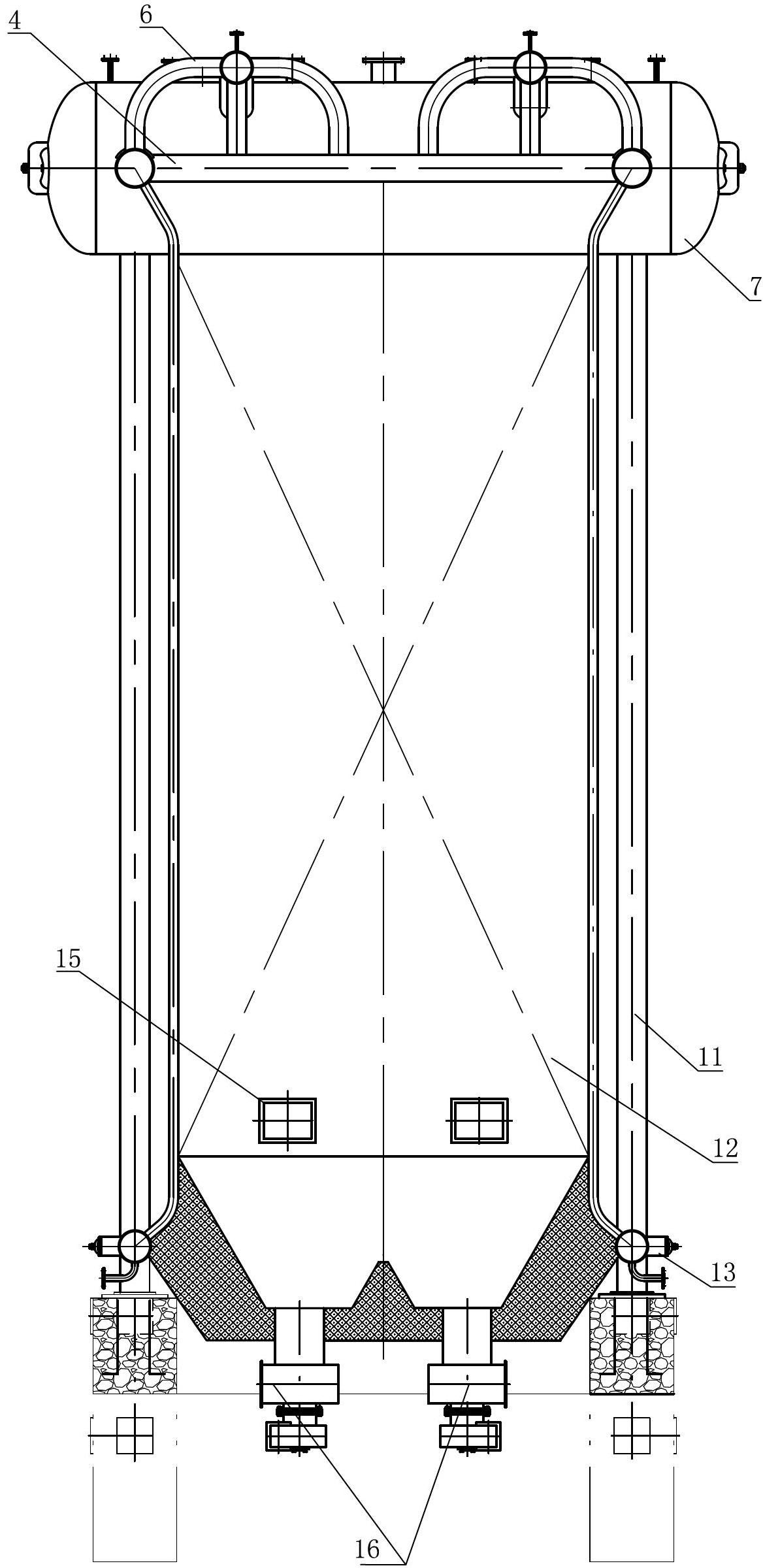

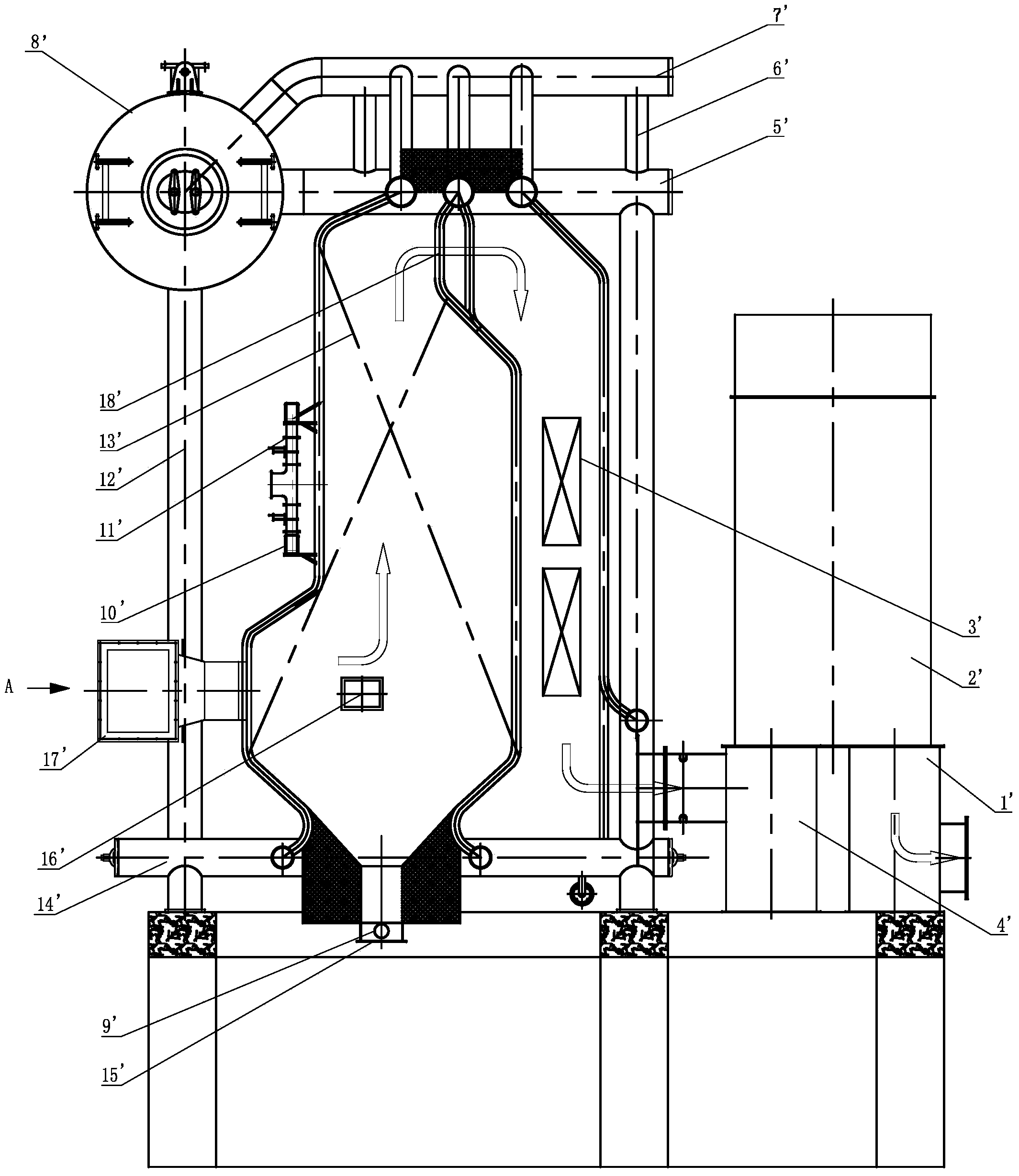

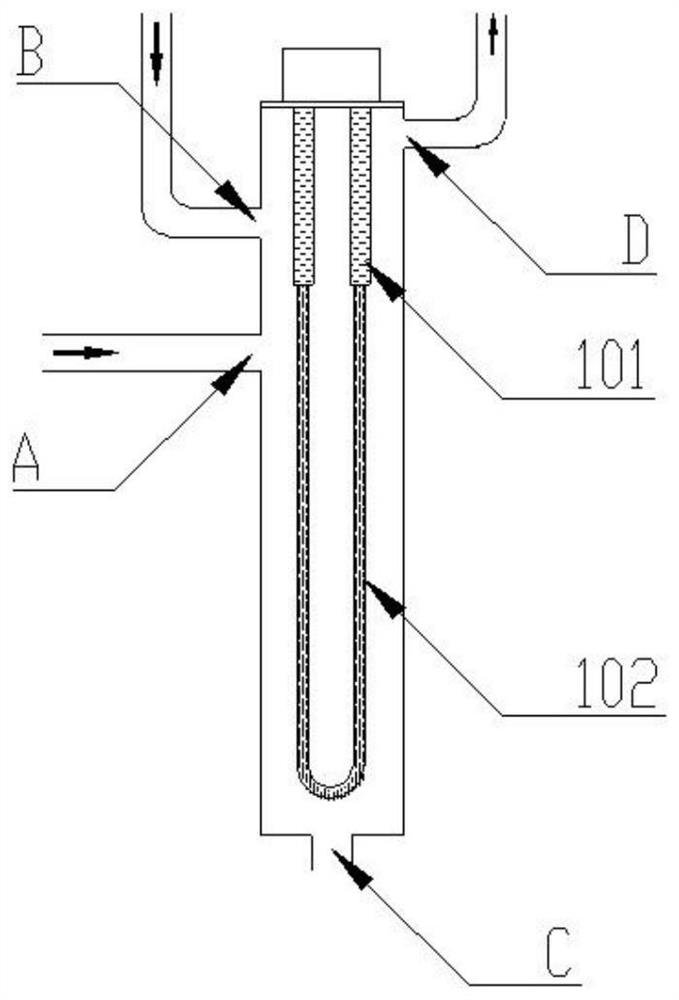

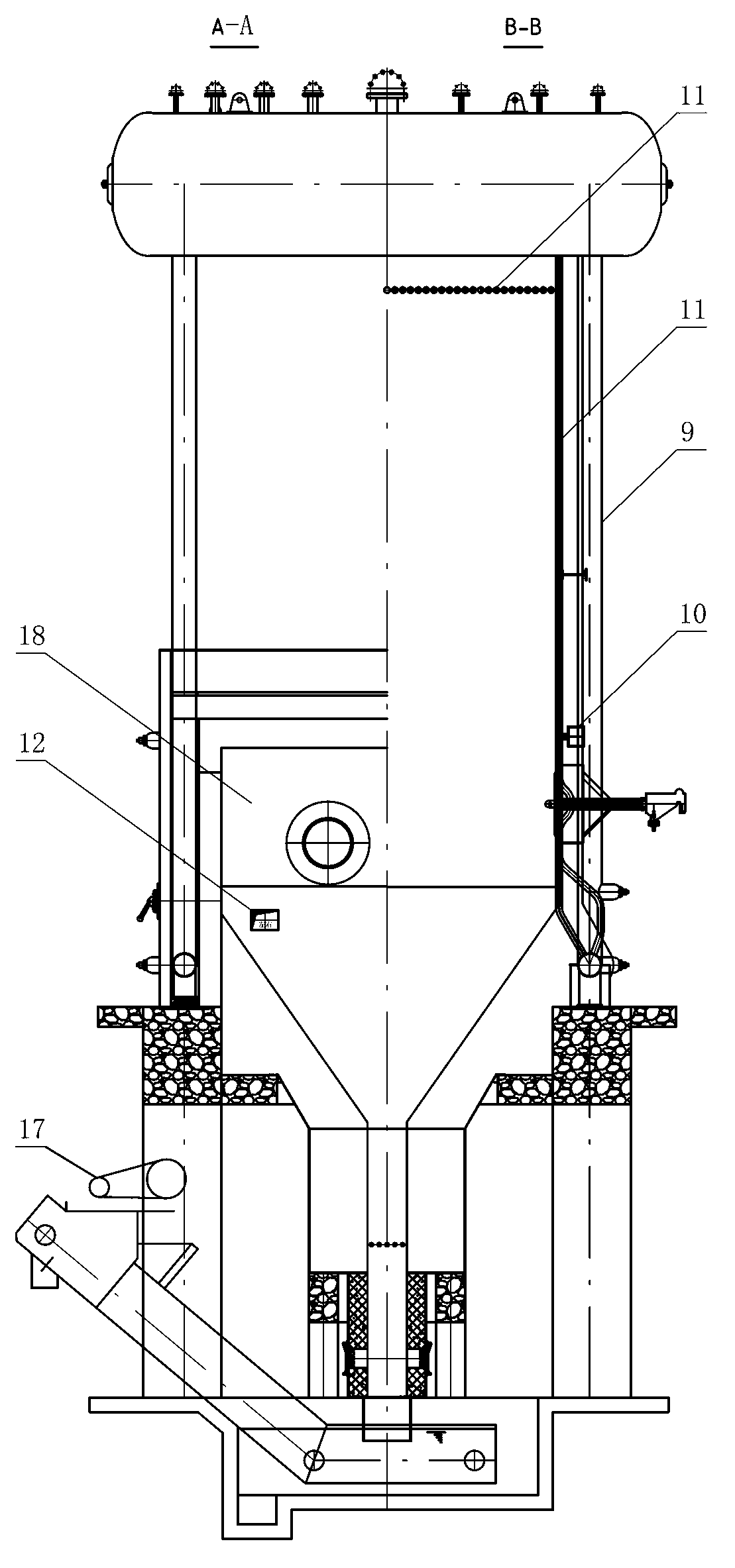

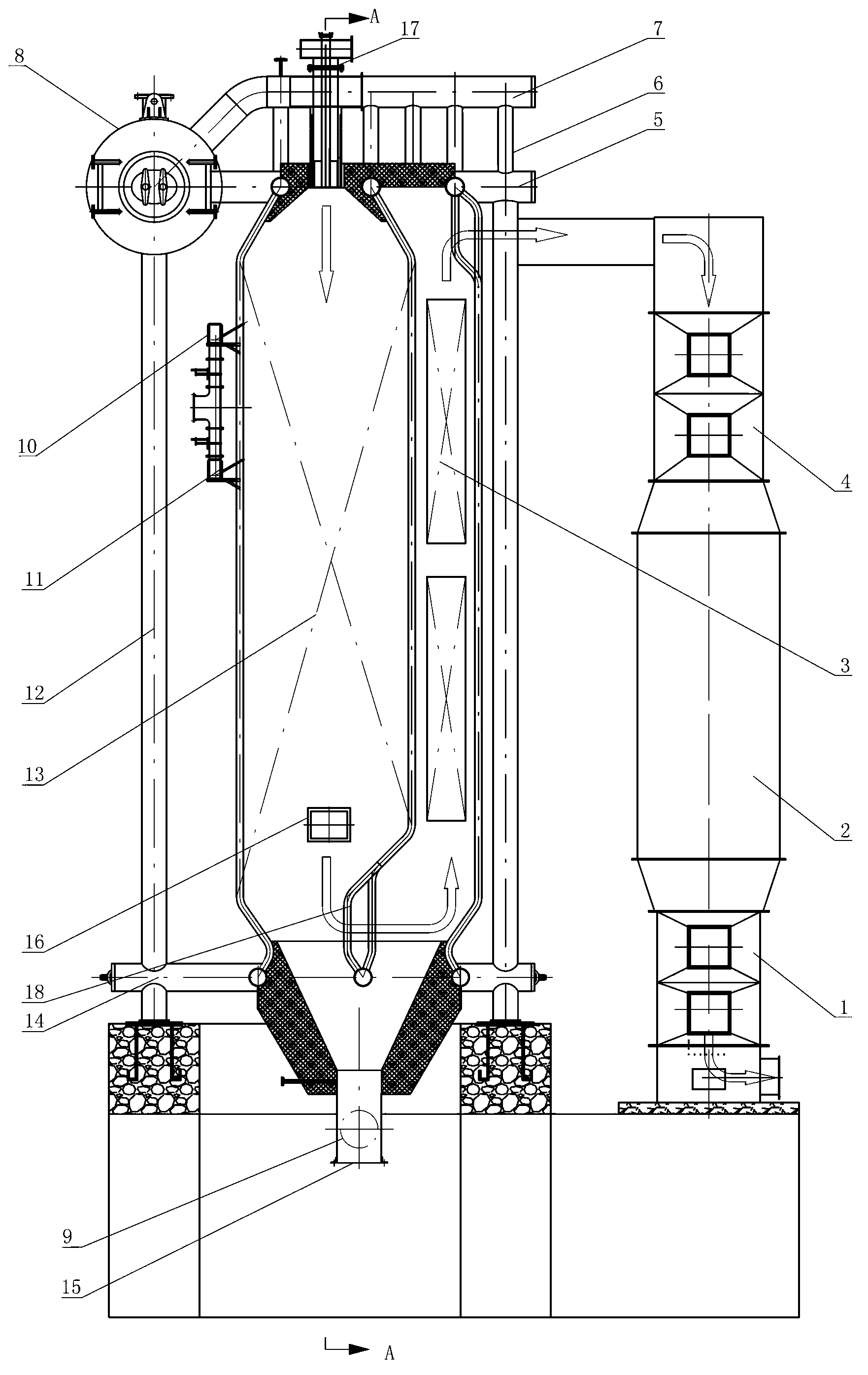

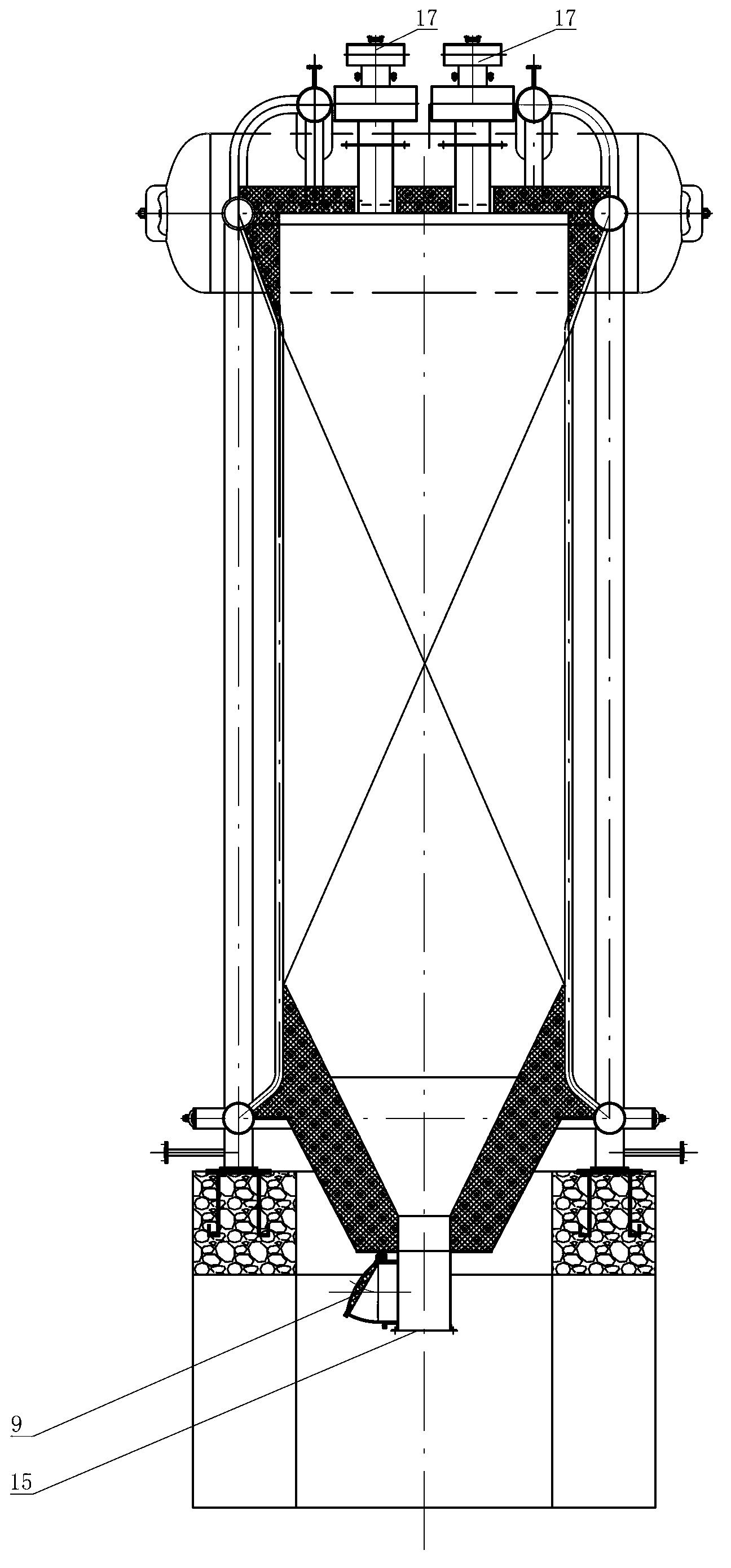

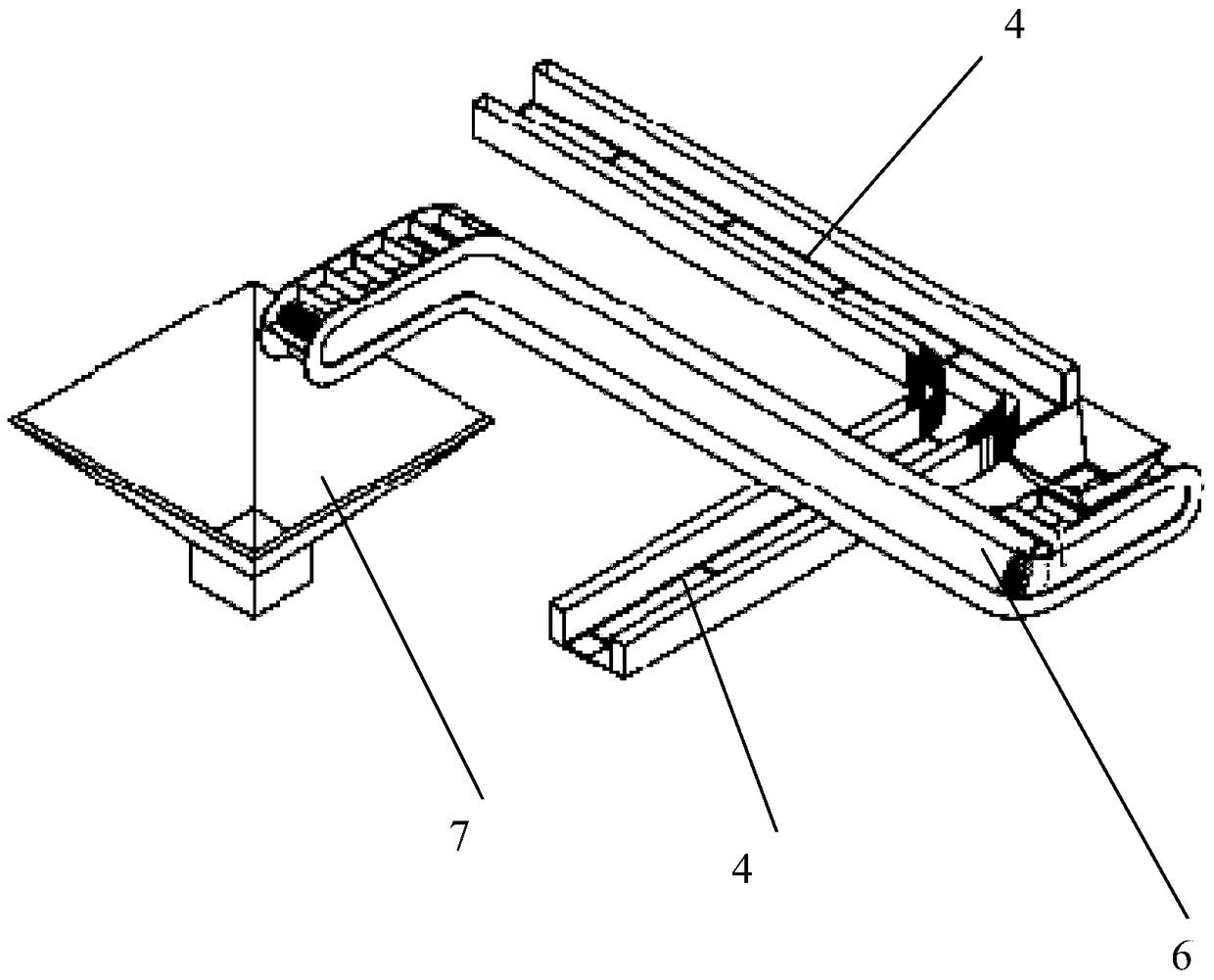

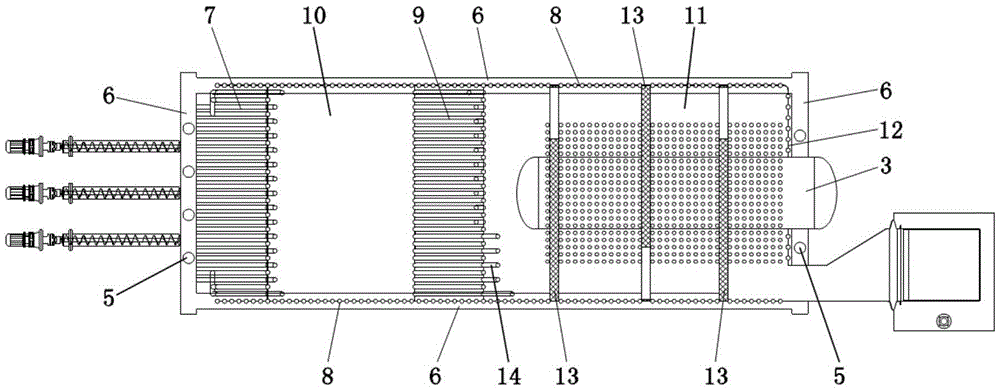

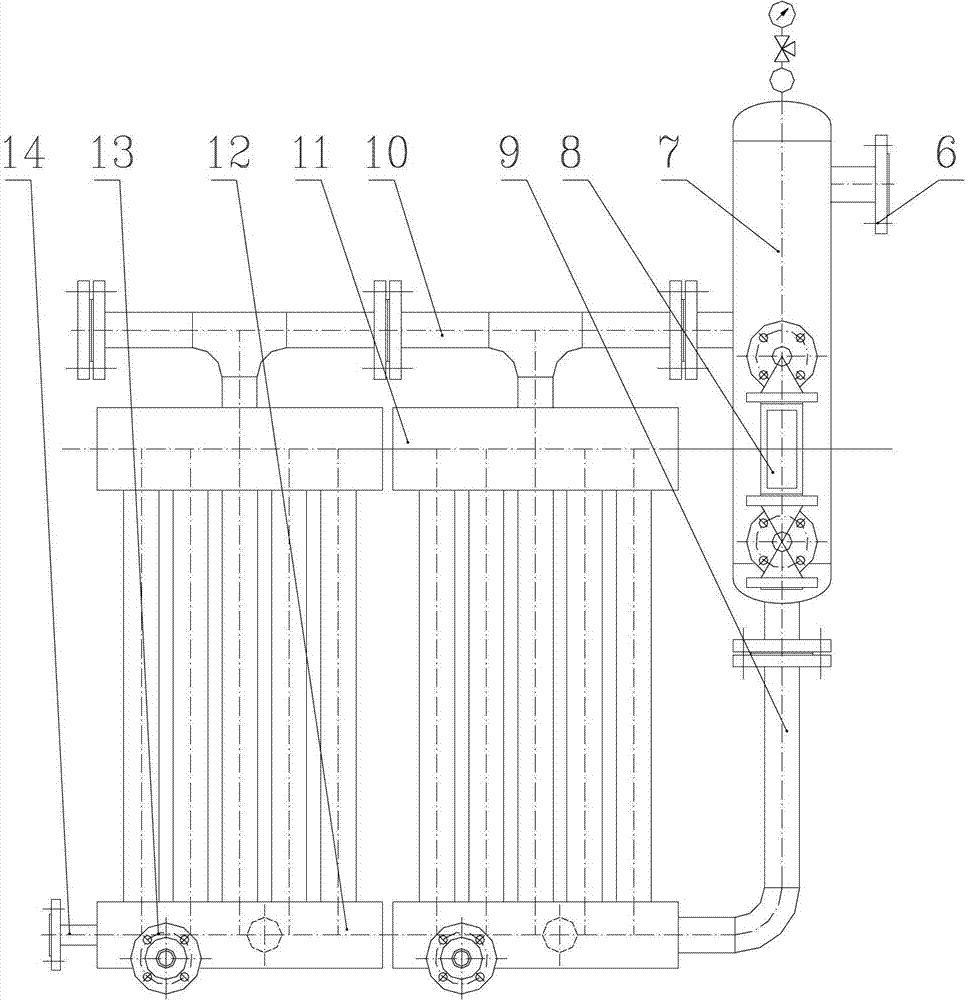

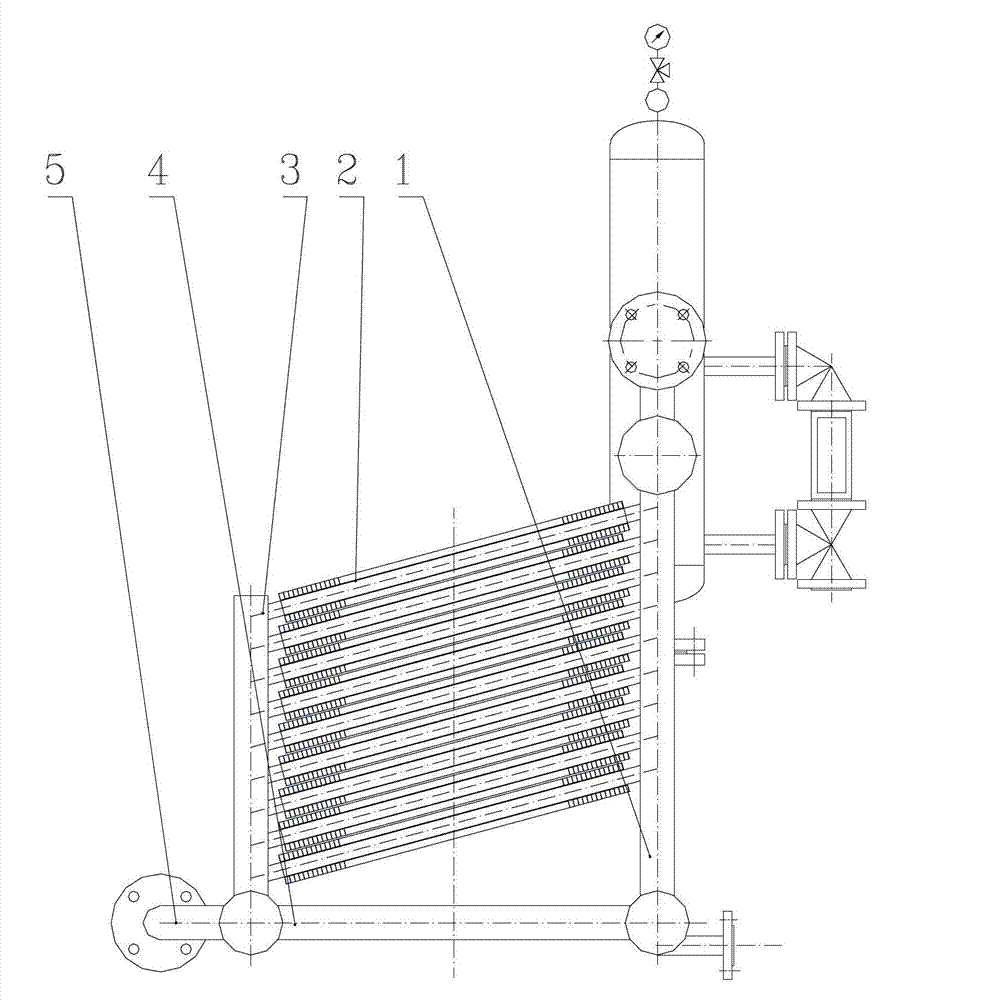

Module-type waste heat vapor generator

ActiveCN103162283BEnsure safetyReliable cycleSteam generation using hot heat carriersComputer moduleEngineering

The invention relates to the technical field of waste heat recovery, in particular to a module-type waste heat vapor generator. The module-type waste heat vapor generator comprises a heat transfer basic module and a steam separator (7), wherein a steam outlet of the upper end of the heat transfer basic module is connected with an inlet of the steam separator (7) through a steam guiding pipe (10). A first outlet of the upper end of the steam separator (7) is connected with a steam discharge pipe (6). A second outlet of the lower end of the steam separator (7) is connected with a water drain pipe (9). The water drain pipe (9) is connected with a water collecting pipe (12) at the lower end of the heat transfer basic module to form a circulation loop. The module-type waste heat vapor generator is novel and simple in structure, the heat transfer basic module can be designed according to the size of quantity of smoke, steam and the number of the heat transfer basic module is decided according to the size of thermal power, and the problems that design, manufacture and use of the waste heat recovery are cockamamie are solved. Work efficiency of design, manufacture and management is improved, safety of thermal power and water circulation is guaranteed, and reliability of steam-water separation is guaranteed, and the module-type waste heat vapor generator is convenient to manufacture, assemble and operate, reliable in circulation, and easy to control.

Owner:上海蕲黄节能设备有限公司

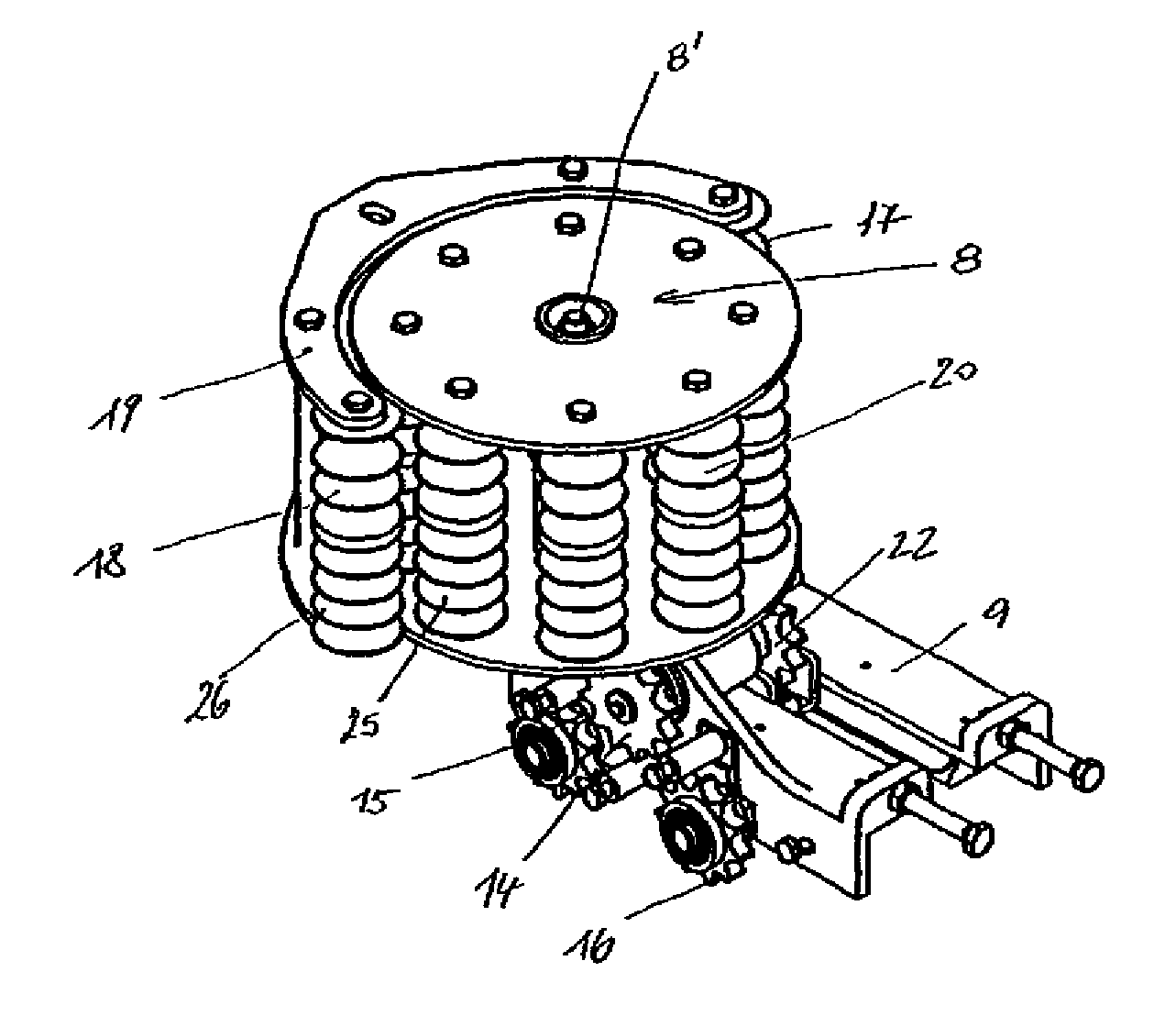

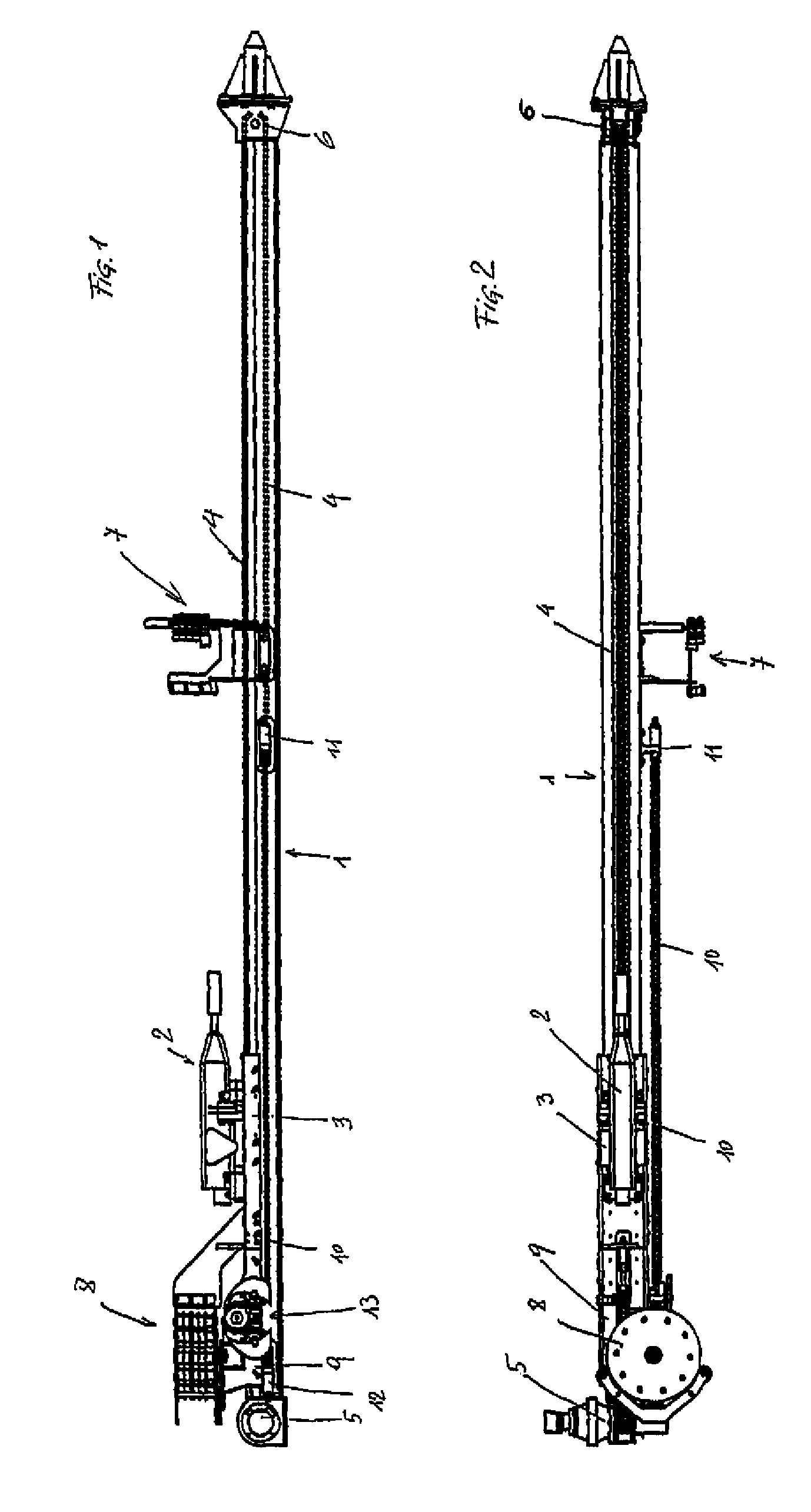

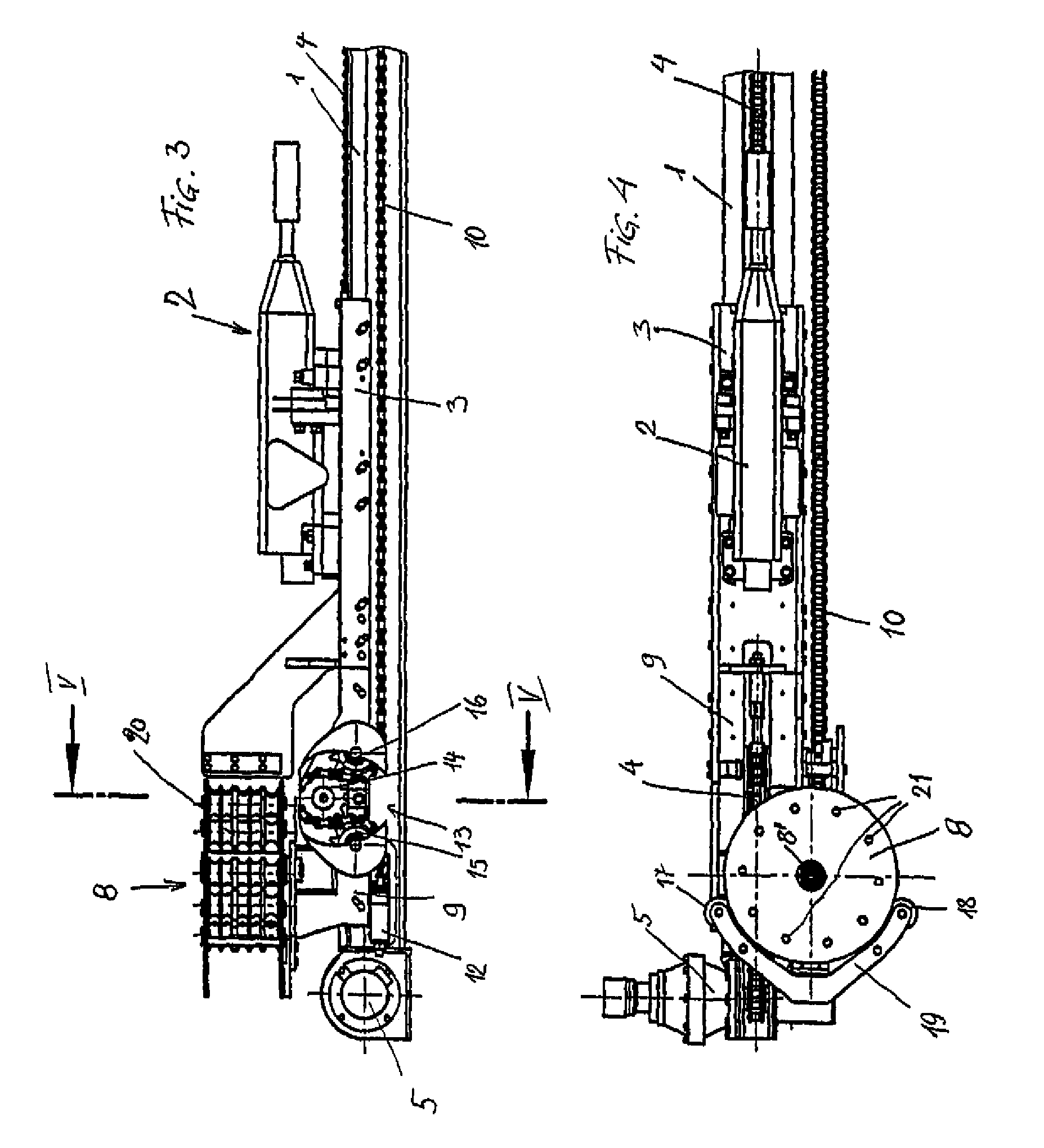

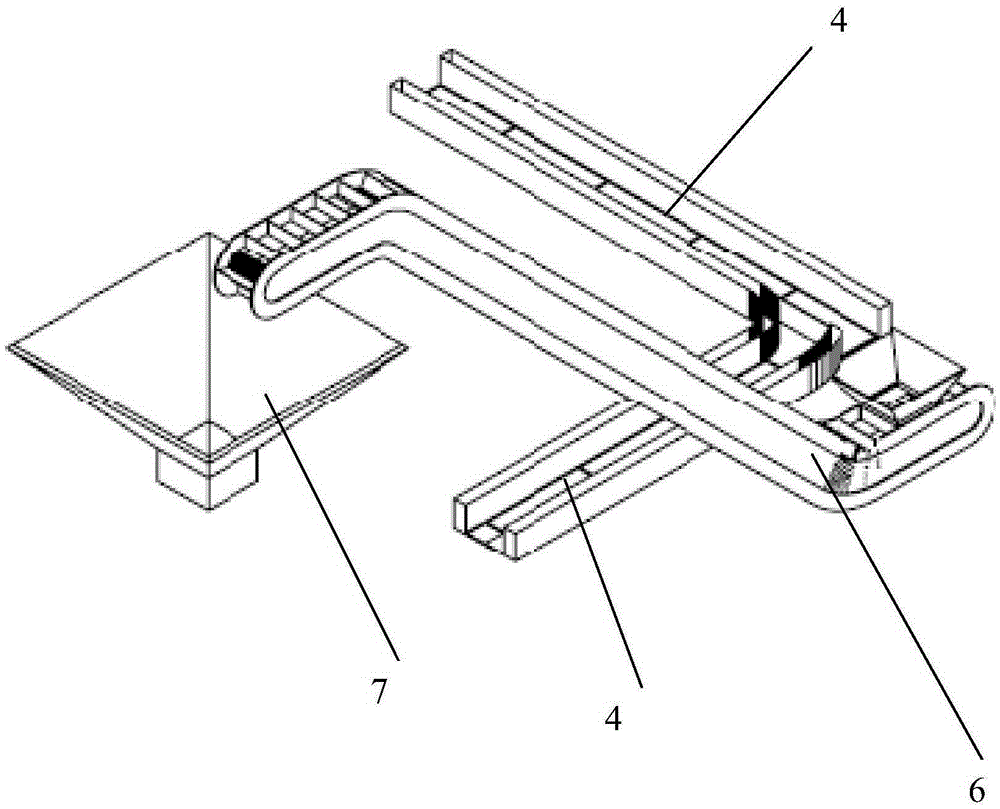

Device for guiding and tensioning supply lines

InactiveUS7735576B2Reliable engagementReliable cyclePipe supportsDrilling rodsLine tubingEngineering

In a device for guiding and tensioning supply lines for working tools movable along a straight guide, e.g. supply lines of a hydraulic hammer drill on an advance mounting, the advance of the working tool is implemented by means of a revolving transport chain driven by a sprocket wheel, and the supply line(s) are guided between the connections on the fixed guide and the connections on the working tool by a tension roller which causes a deflection about 180° and is movable in advance direction downstream the working tool conjointly therewith in the same direction but at half the advance speed, wherein the tension roller is slidably guided on the guide for the working tool transversely to its rotation axis, and wherein a pinion engages the transport chain for driving the movement of the tension roller and interacts with a fixed chain on the opposite side. To realize a controlled movement of the tension roller in both direction, a further transport wheel (14) for the advancement of the tension roller (8) is mounted onto the shaft (23) of the pinion (22) that engages the transport chain (4), for interaction with a fixed chain, a rack, a fixed traction rope, or the like.

Owner:WIMMER ALOIS

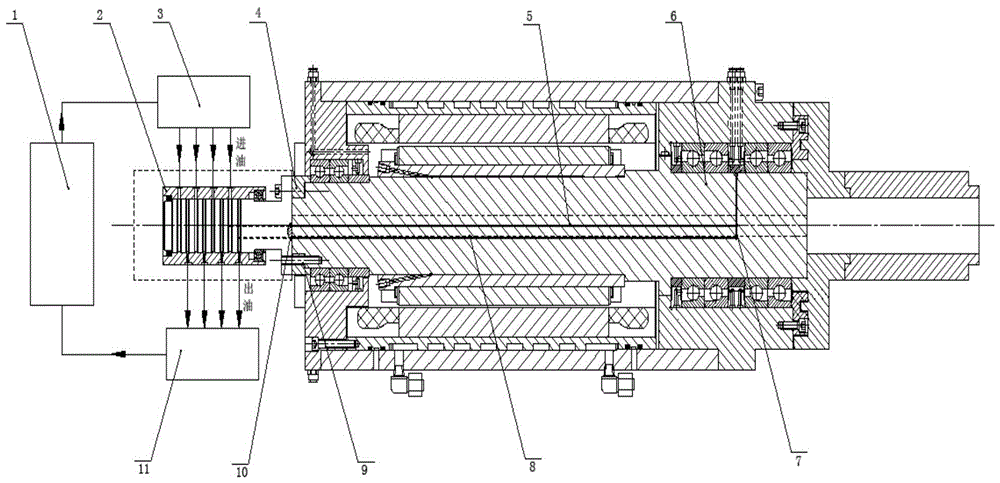

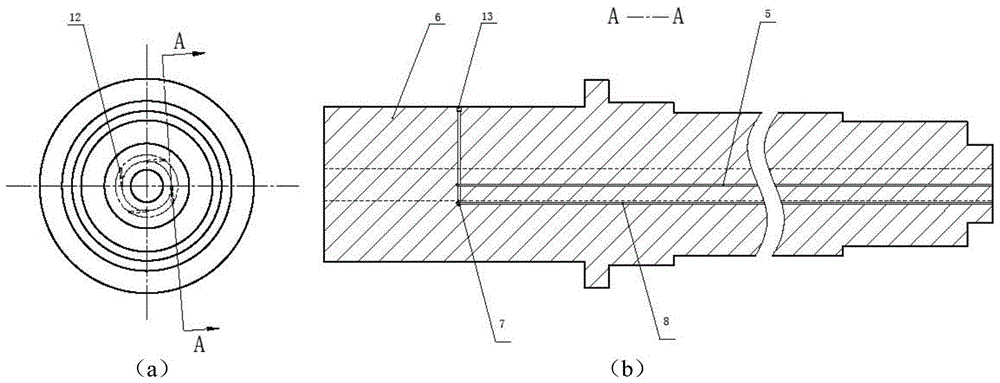

A Cooling System for Electric Spindle Core

InactiveCN104108047BIncrease cooling areaIncreased turbulenceMaintainance and safety accessoriesElectricityThermal deformation

The invention discloses an electric spindle core cooling structure and system. An electric spindle core is provided with a plurality of U-shaped cooling units consisting of straight-hole channels; the inflow channel inlet and reflow channel outlet of each cooling channel unit are formed in a staggered way in the back end face of the electric spindle core; a connecting channel is formed inside the electric spindle core close to a front bearing to connect the inflow channel with the reflow channel; specific to the aim of realizing leading-in and leading-out of a cooling channel unit cooling medium, a shaft head flange type multi-channel high-speed rotary joint is tightly connected with the back end face of the conventional electric spindle core through a back bearing sleeve, an inflow channel header and a reflow channel header are provided, and an electric spindle core forced circular cooling system is constructed with an oil-water cooling system. By adopting the electric spindle core cooling structure and system, direct, rapid and efficient forced circular cooling of the electric spindle core can be realized, the problem of heat dissipation caused by long-term high-power processing of an electric spindle is solved, thermal deformation of the electric spindle core is reduced, and the heat stability of the electric spindle is enhanced.

Owner:XI AN JIAOTONG UNIV

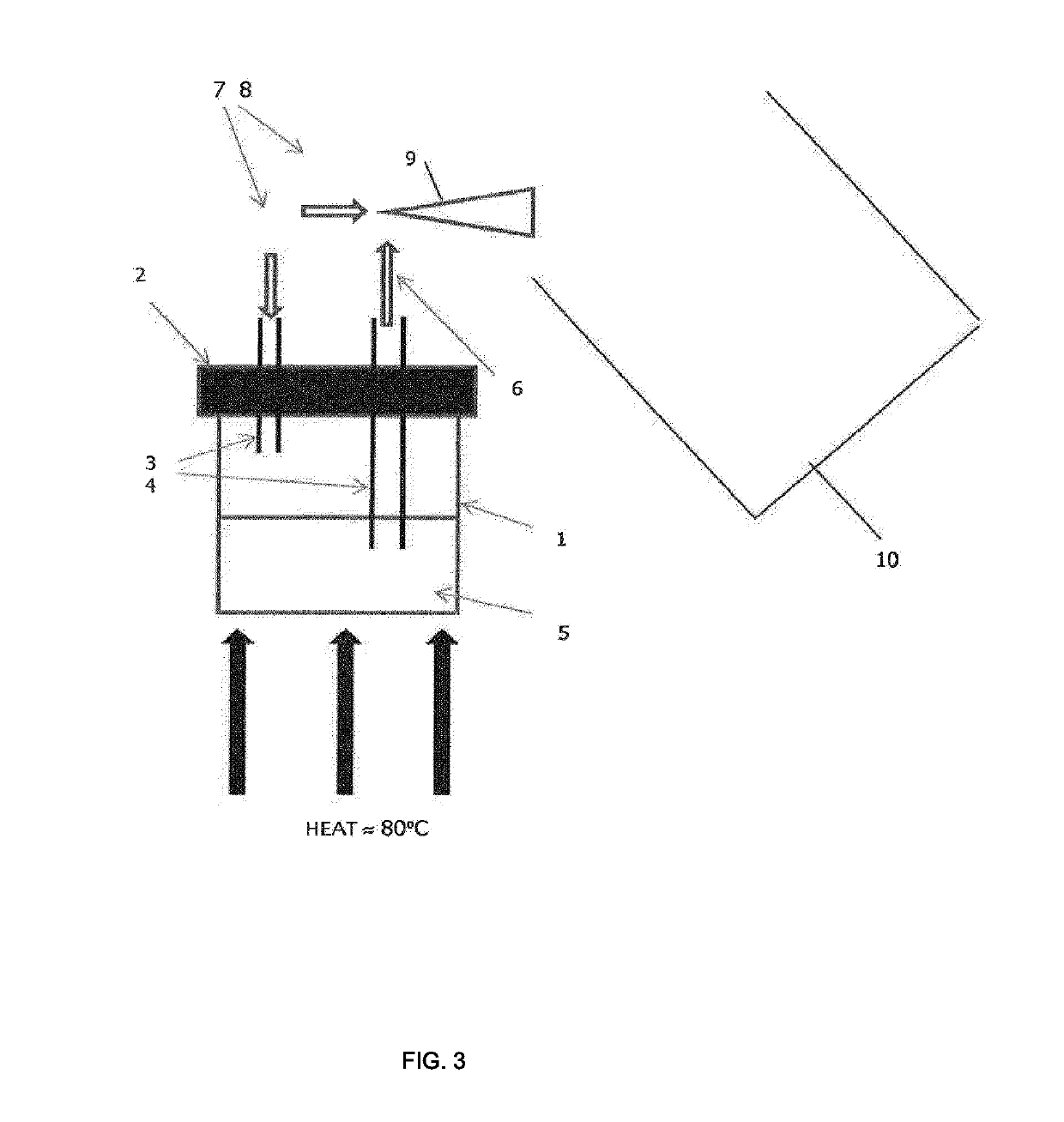

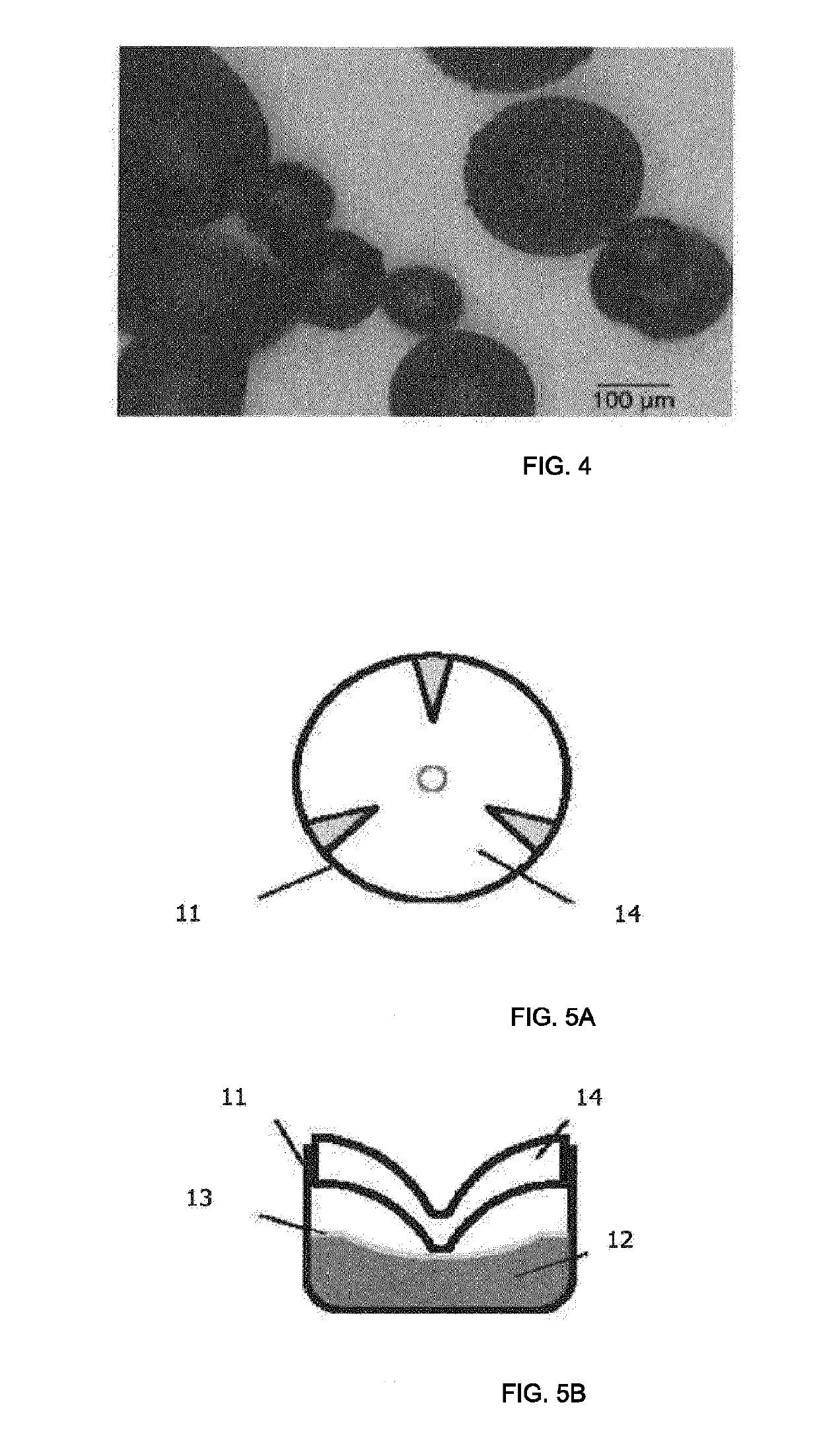

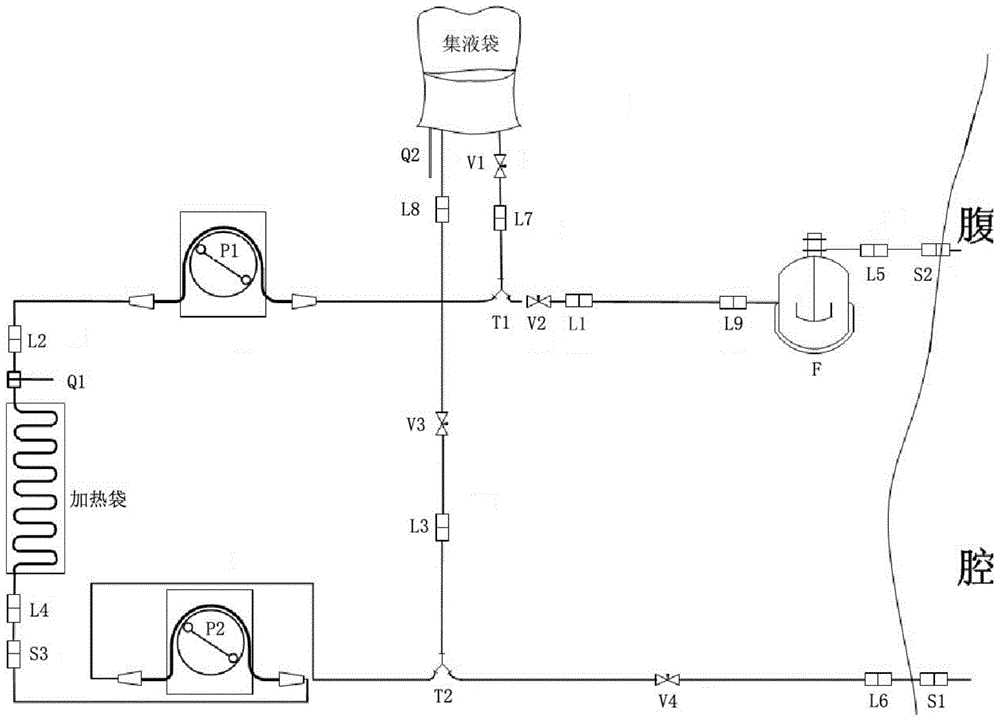

Intraperitoneal hyperthermic chemotherapy circulation circuit device

ActiveCN103751880BFulfil requirementsFree from destructionPressure infusionTherapeutic coolingAbdominal cavityTreatment effect

The invention provides a chemohyperthermia circulation pipeline device for intraperitoneal chemohyperthermia. The circulation pipeline device is adjusted to adapt to different therapy periods by on and off of clips to meet requirements of the intraperitoneal chemohyperthermia. System simplicity and reliability can be achieved while liquid medicine is undamaged by using heating plates for heating. Using a temperature tee joint is convenient for arrangement of temperature detection points and can guarantee precision in temperature detection and control so as to guarantee therapeutic effects of the intraperitoneal chemohyperthermia. Using a liquid collection bag is convenient for infusion of liquid medicine and convenient to operate, and air is prevented from being mixed in the liquid medicine during circulation, so that therapeutic effects can be guaranteed. The liquid medicine is completely recovered to the liquid collection bag after therapy, and leakage and environment pollution are prevented. Pump pipes are arranged on two sides of a heating bag to avoid inflation of the heating bag. Human tissue microemboli can be effectively filtered by a filter to prevent pipeline blocking during circulation, so that reliability in circulation is realized.

Owner:GUANGZHOU BRIGHT MEDICAL TECH

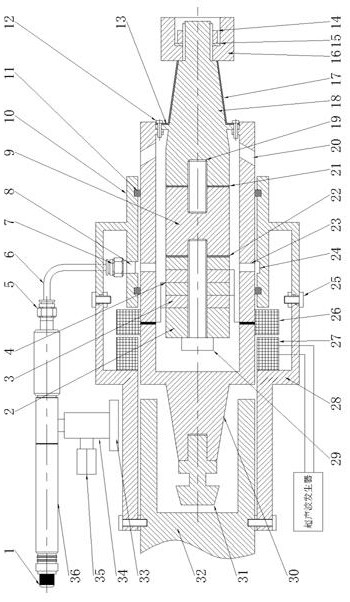

3D printing online high-temperature ultrasonic milling system based on main shaft without cooling hole

PendingCN112122672ASimple structureNo pollutionMilling equipment detailsMetal working apparatusCold airEngineering

The invention discloses a 3D printing online high-temperature ultrasonic milling system based on a main shaft without a cooling hole. The 3D printing online high-temperature ultrasonic milling systemcomprises a wireless power transmission mechanism, a transduction luffing mechanism and a cutter handle. The transduction luffing mechanism is arranged in an inner cavity of the cutter handle, a mainshaft shell sleeves the cutter handle, and a sealing sleeve is arranged between one end of the main shaft shell and the cutter handle. The sealing sleeve is in clearance fit with the cutter handle, sealing rings are arranged between the sealing sleeve and the cutter handle at intervals, and cutter handle air holes are formed in the portion, between the two sealing rings, of the cutter handle at intervals in the circumferential direction. Air inlet holes are formed in the portions, corresponding to the cutter handle air holes, of the sealing sleeves, the air inlet holes are connected with an air cooling device, and air outlet holes are formed in the portions, outside the sealing sleeves, of the lower end of the cutter handle at intervals in the circumferential direction. According to the 3Dprinting online high-temperature ultrasonic milling system based on the main shaft without the cooling hole, cold air is fed into the cutter handle to reduce the internal temperature, heat of an amplitude-change pole is prevented from being transmitted to a transducer by coating a heat insulation coating, and the working stability in a high-temperature environment is ensured.

Owner:HENAN POLYTECHNIC UNIV

Automatic collecting and filling device of ball projectiles for recreation and collecting method of automatic collecting and filling device

The invention discloses an automatic collecting and filling device of ball projectiles for recreation and a collecting method of the automatic collecting and filling device. The automatic collecting and filling device comprises a track and inclined ground, wherein the track is mounted on a ball projectile vehicle body and allows the ball projectile vehicle body to move thereon, the inclined ground is arranged below a shooting range of the ball projectiles, one or more ball projectile return grooves are formed in the middle of the inclined ground, a ball projectile conveying belt for conveying the ball projectiles in the ball projectile return groove to a centralizing point is disposed at the tail end of each ball projectile return groove, a collector for collecting the ball projectiles on the ball projectile conveying belt in a centralized manner is mounted at the other end of the ball projectile conveying belt, and a ball projectile lifting device for lifting the ball projectiles inside the collector to a ball storage cabin in a centralized manner is connected to the bottom end of the collector.

Owner:北京万达文旅规划设计院有限公司

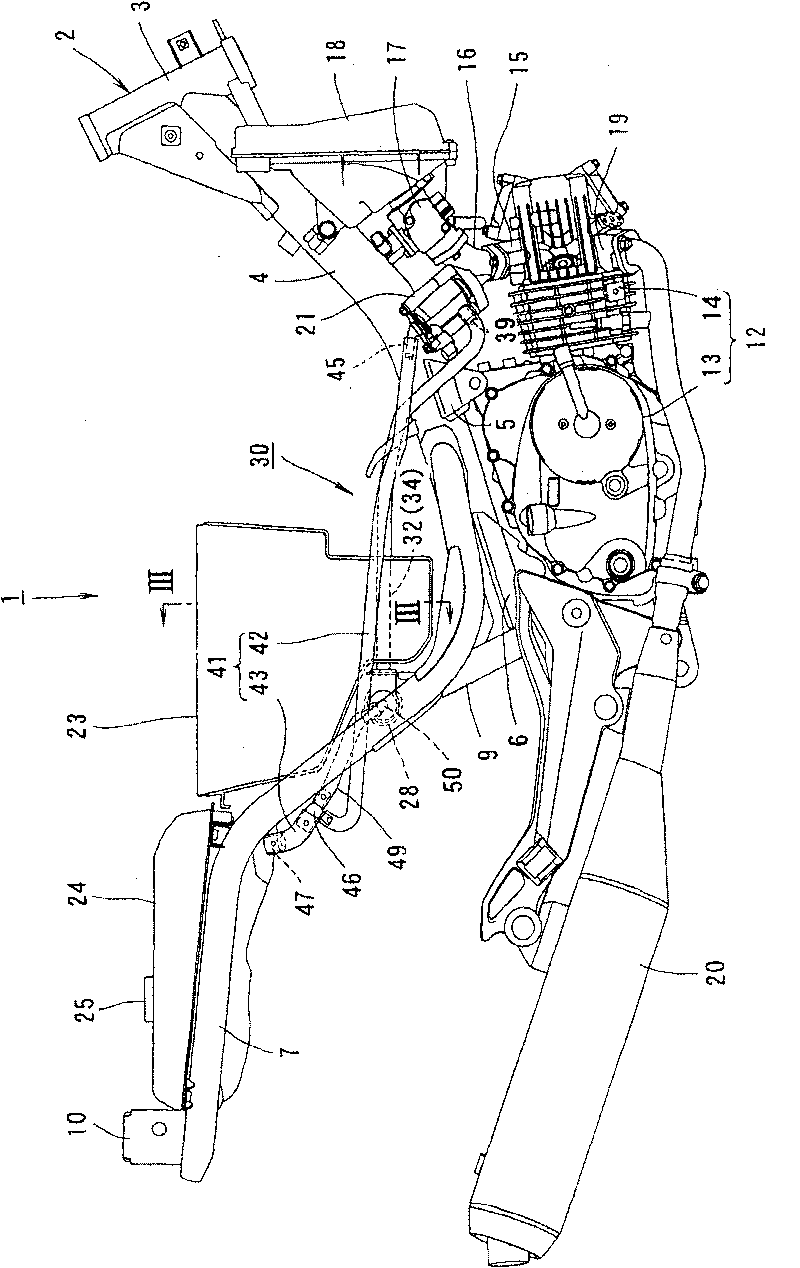

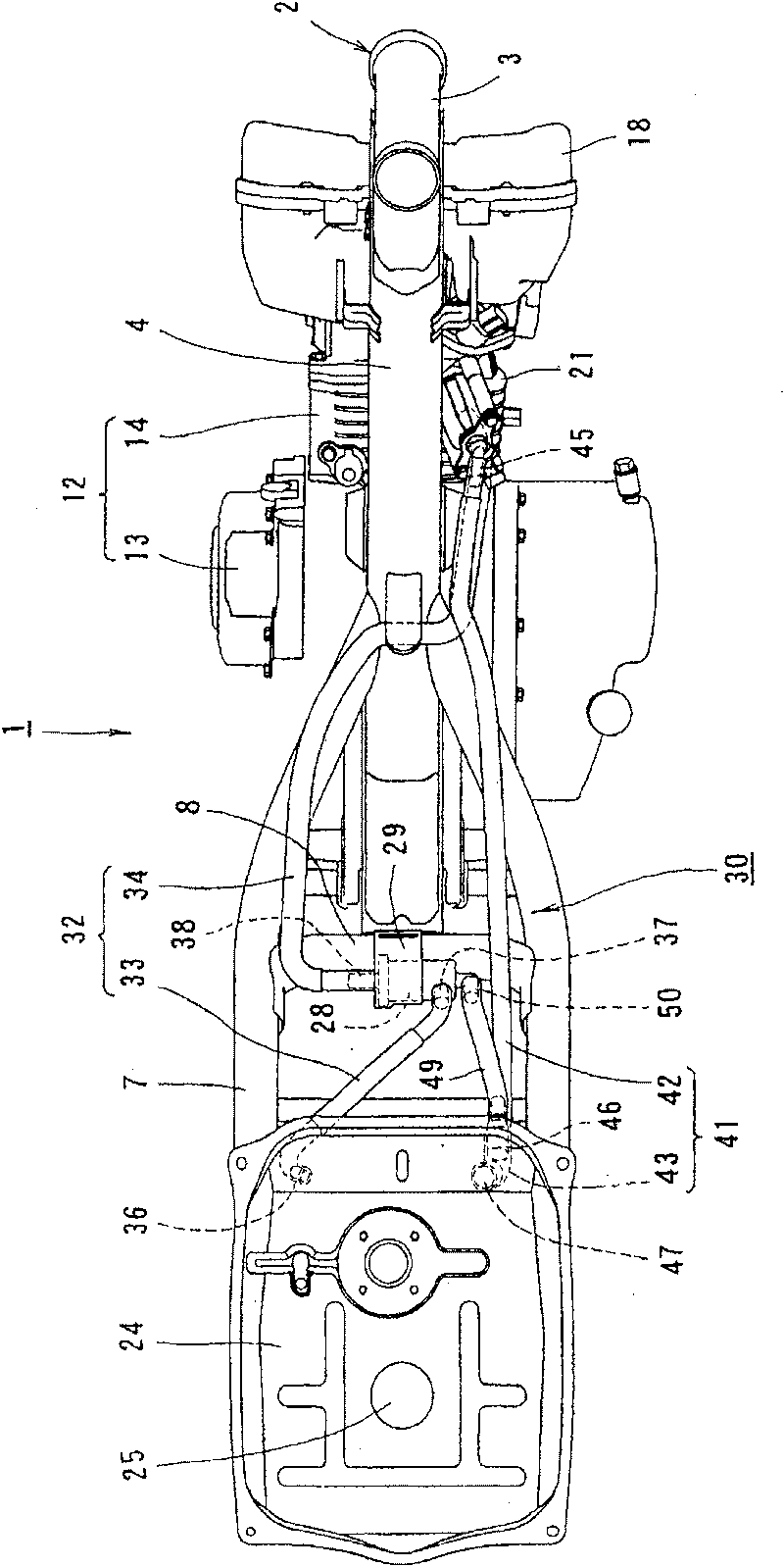

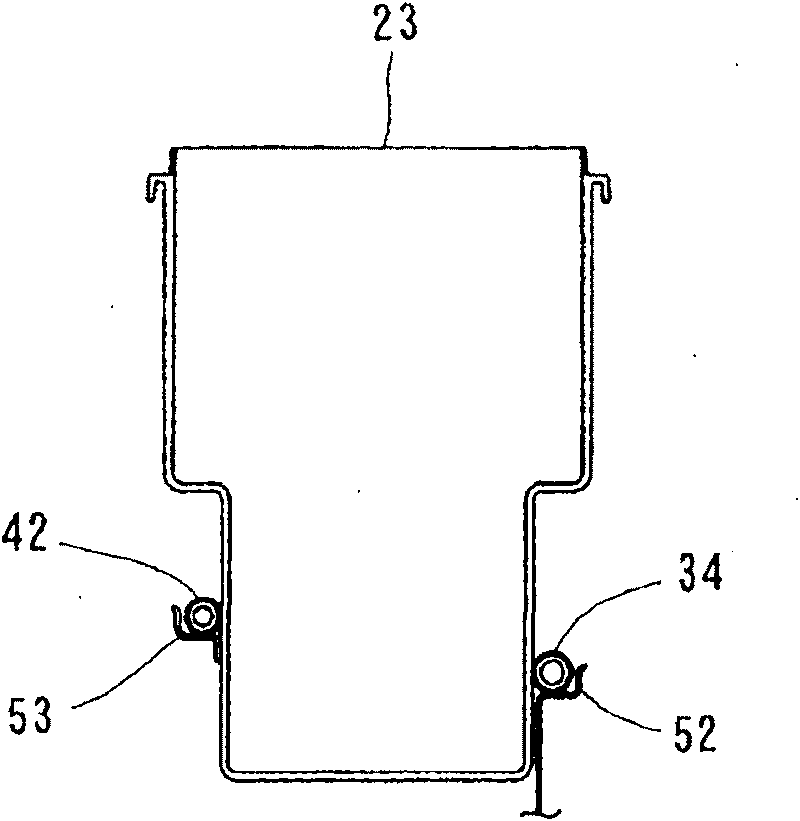

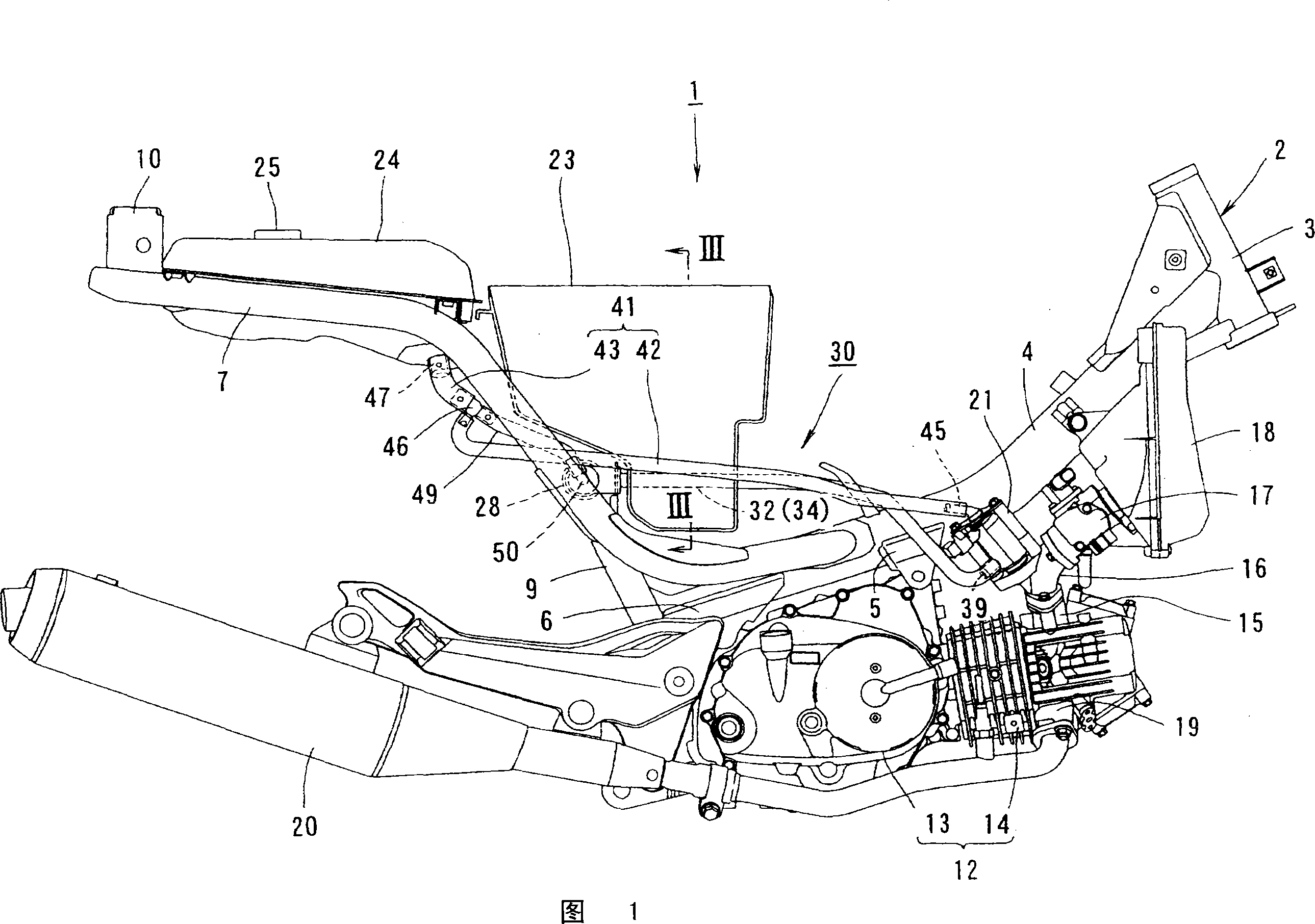

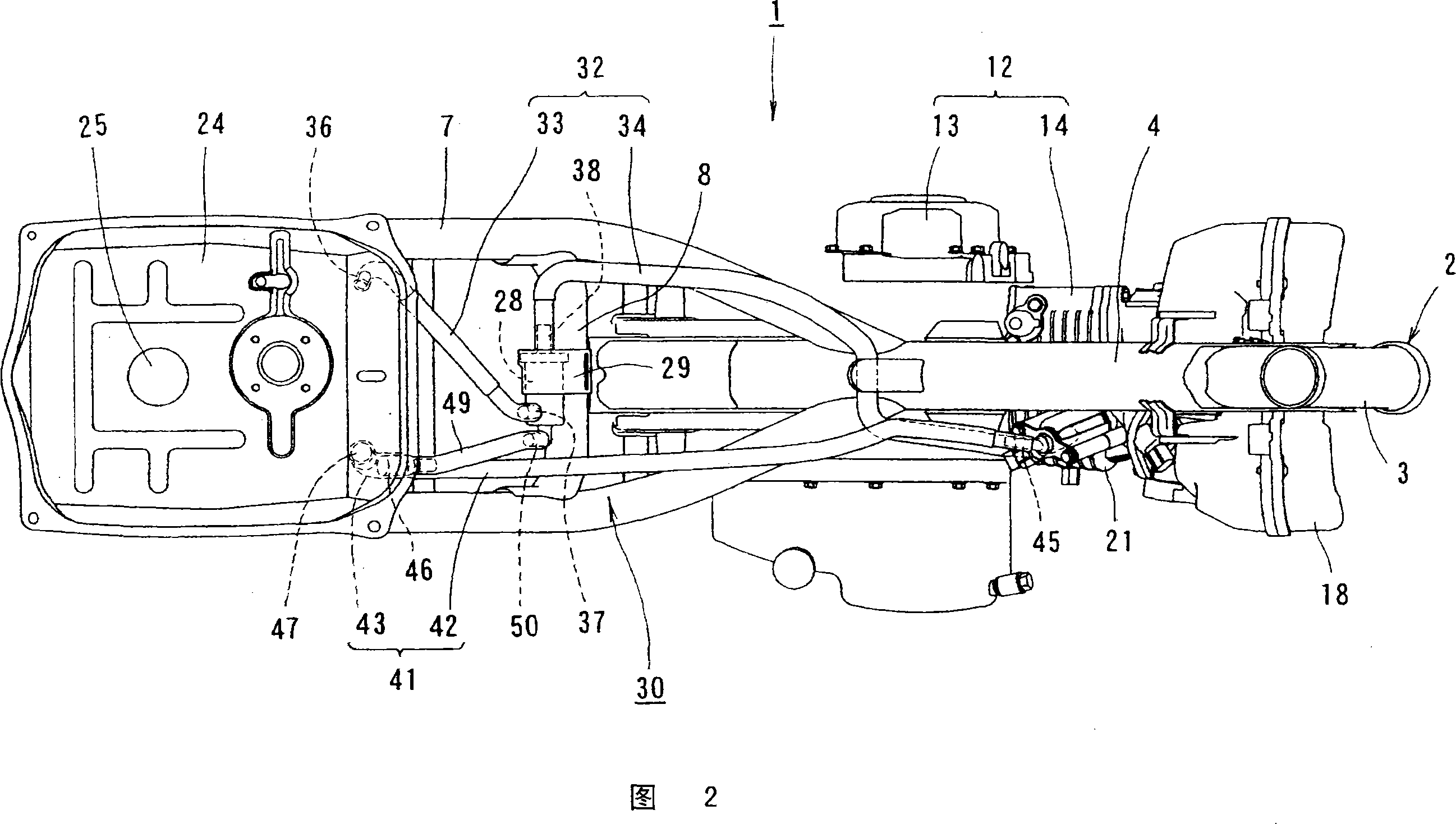

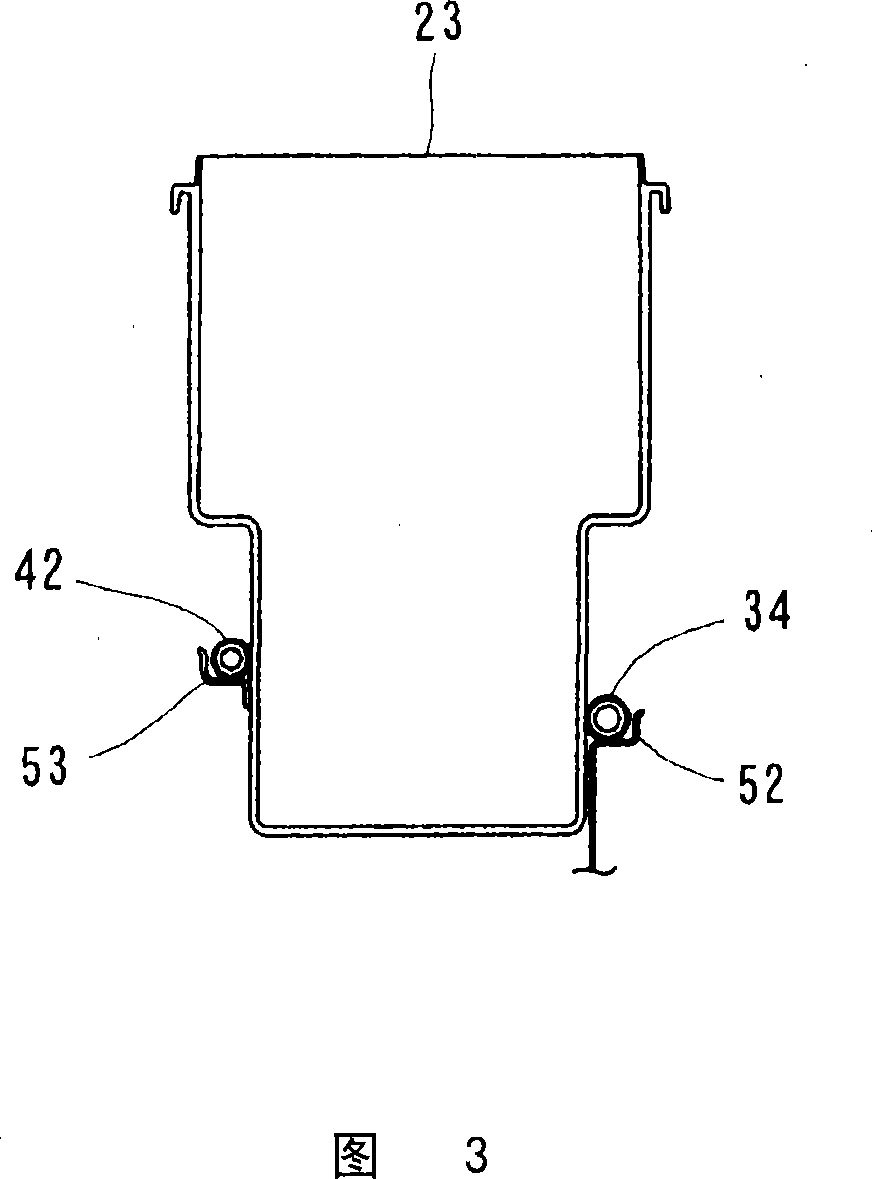

Fuel feeding device for motorcycle

InactiveCN101210532BReliable cycleNo reduction in capacityInternal combustion piston enginesLow-pressure fuel injectionFuel filterFuel supply

Owner:SUZUKI MOTOR CORP

Fuel feeding device for motorcycle

InactiveCN101210532AReliable cycleReduce capacityInternal combustion piston enginesLow-pressure fuel injectionFuel filterFuel supply

The present invention provides a fuel supply device for motorcycle, a fuel flow direction of a fuel filter setting nearby the lower side of a storing box is orientated as vehicle width direction, a fuel feeding pipe being connected to a fuel injection device from a fuel box by way of the fuel filter is configured to descend towards the fuel injection device from the fuel box always, a fuel refluxpipe for cycling overfull fuel to the fuel box from the fuel injection device is always ascending towards the fuel box from the fuel injection device, a recycle pipe branching from a part higher thanthe fuel filter at middle part of the fuel reflux pipe extends by means of be always descending to connect to the fuel filter.

Owner:SUZUKI MOTOR CORP

Double-negative-pressure ink circulation printer

PendingCN114590031AReduce disturbanceReduce air bubblesOther printing apparatusEngineeringMechanical engineering

The invention discloses a double-negative-pressure ink circulation printer which comprises a first-stage ink barrel, a second-stage ink box, a nozzle and a circulation ink box. A first ink conveying mechanism for conveying ink to the second-stage ink box is connected between the first-stage ink barrel and the second-stage ink box; a second ink conveying mechanism for conveying ink to the primary ink barrel is connected between the circulating ink box and the primary ink barrel; the secondary ink box is arranged above the spray head and connected with a first negative pressure mechanism, and the circulating ink box is connected with a second negative pressure mechanism used for sucking ink at the spray head. The double-negative-pressure ink circulation printer can reduce the phenomenon of needle breakage of the nozzle and ensure normal operation of the printer.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

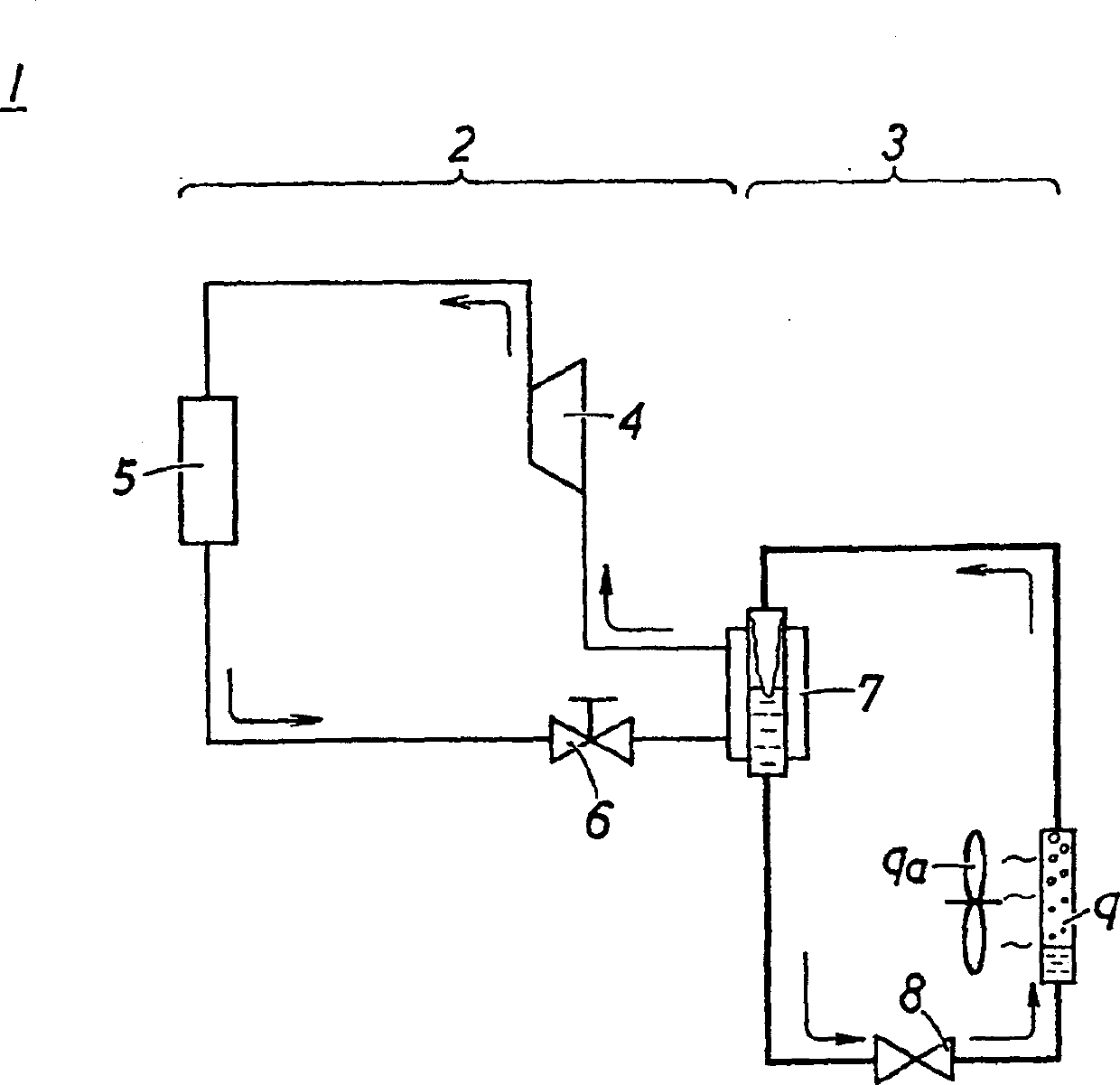

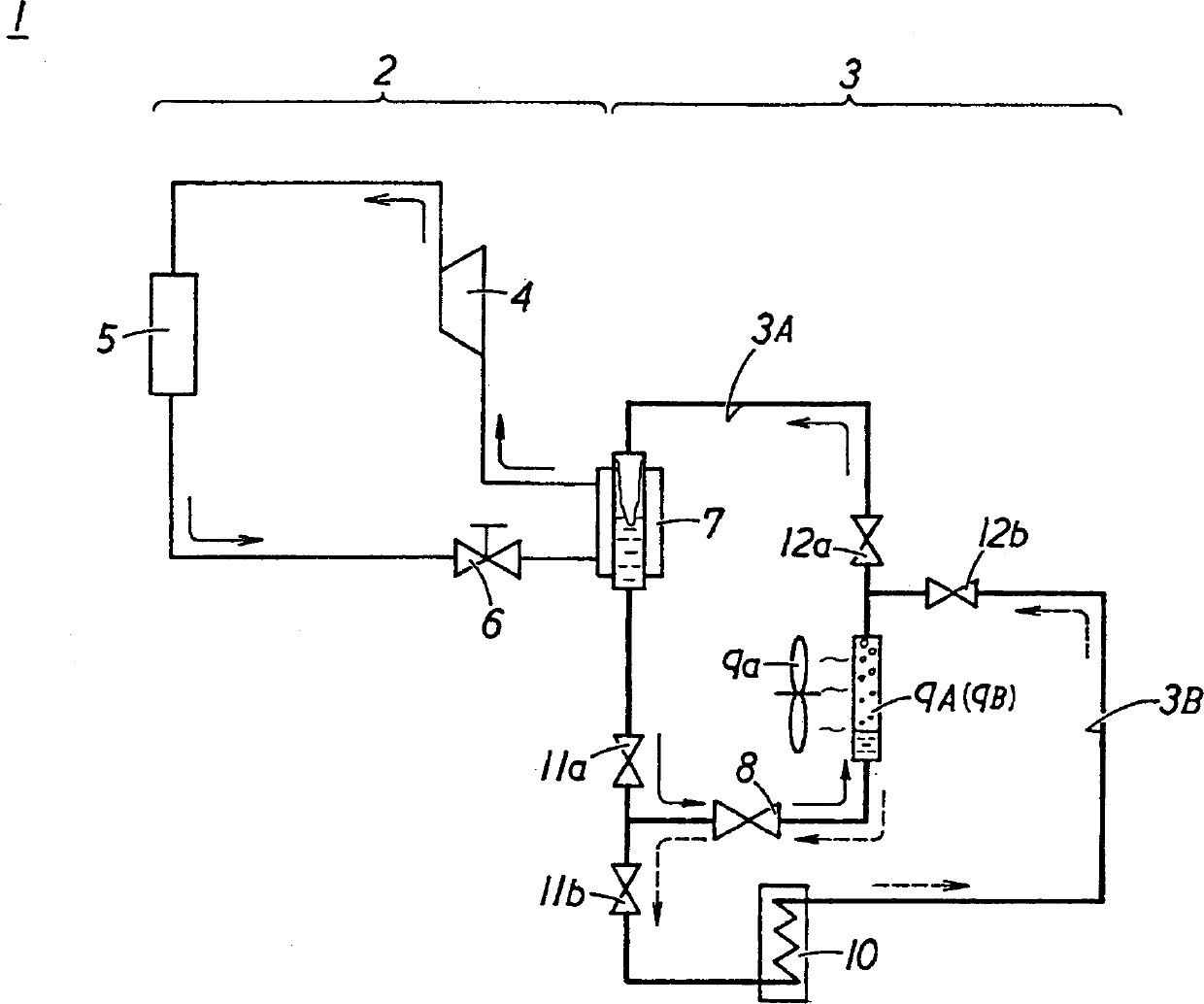

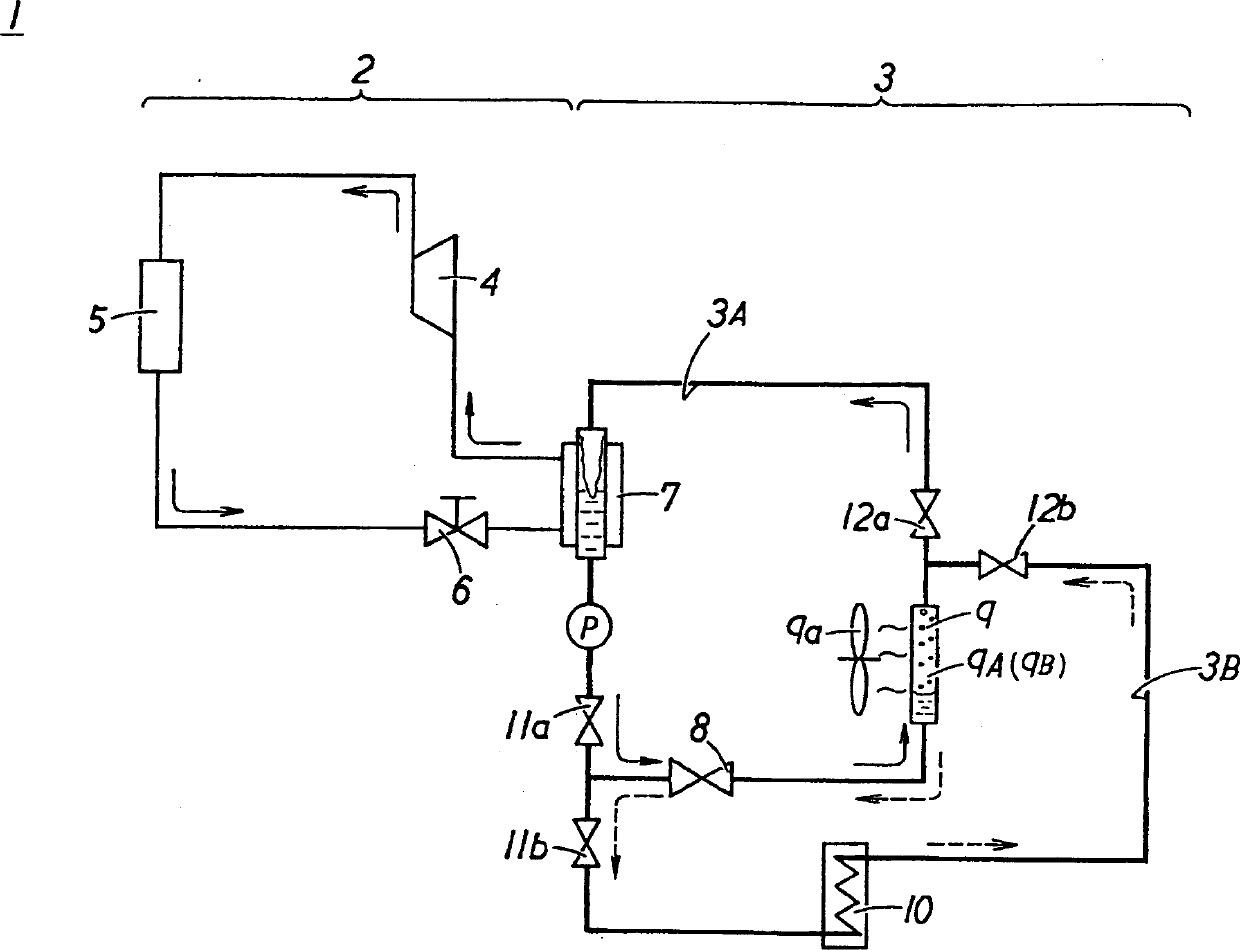

Heat pump system of cobination of ammonia cycle and carbon dioxide cycle loop

InactiveCN1149365CReliable cycleCompression machines with non-reversible cycleCompression machines with cascade operationProcess engineeringAmmonia

A novel heat pump system capable of carrying out a cooling (refrigerating) operation or a heating (room heating) operation with ammonia and carbon dioxide, natural media, utilized in a combined state. The heat pump system (1) comprises a combination of an ammonia cycle (2), and a carbon dioxide cycle (3), and is characterized in that a carbon dioxide medium is circulated in the carbon dioxide cycle (3) by heating or cooling a part of the cycle, in addition to utilizing a natural circulation phenomenon in which a liquid head difference is formed in a carbon dioxide medium in the cycle without incorporating a compressor in the cycle, structural members of the ammonia cycle (2) being installed in a place isolated from a machine for cooling and heating an object material.

Owner:金尾 英敏 +1

Explosive composition for use in telescopically expanding non-lethal training ammunition

ActiveUS11040923B2Reduce deviationLess aggressiveTraining ammunitionNon-explosive desensitisers/phlegmatisersParaffin waxExplosive Agents

An explosive composition for use in telescopically expanding non-lethal training ammunition comprises tetrazene and paraffin wax. The explosive composition can be used as a primer and / or as a source of energetic material in a telescopically expanding non-lethal training cartridge; it can be used to propel a projectile from a telescopically expanding non-lethal training cartridge; and / or it can be used to expand telescopically a non-lethal training cartridge within a host gun.

Owner:UTM IP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com