Continuous drilling and cyclic pouring integrated piling tool

A tool and circulation device technology, applied in the direction of rotary drilling, percussion drilling, drilling pipe, etc., can solve the problems of multi-time, mismatch and lag, failure to comprehensively consider, etc., to achieve simple operation, reliable circulation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

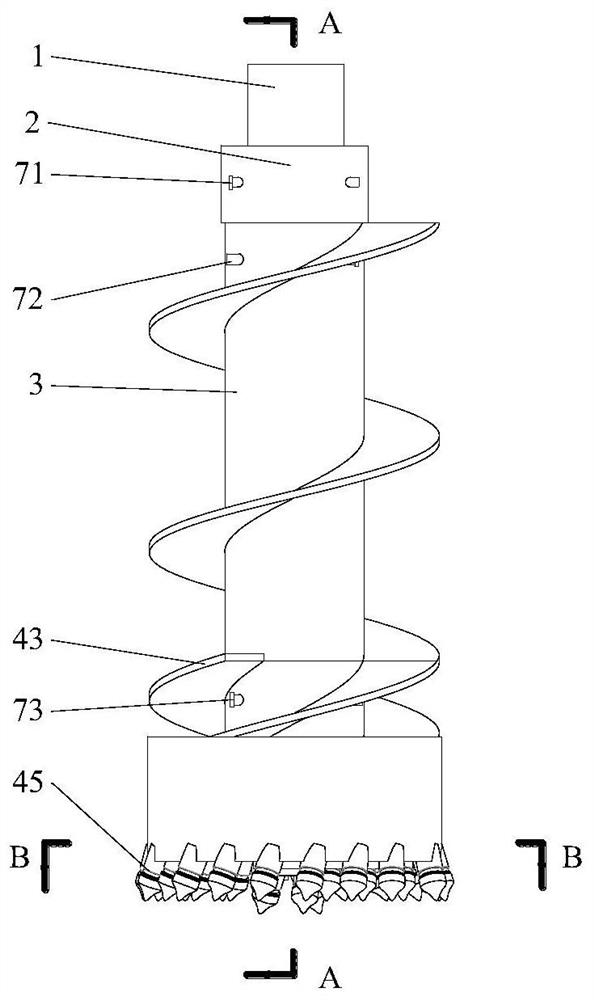

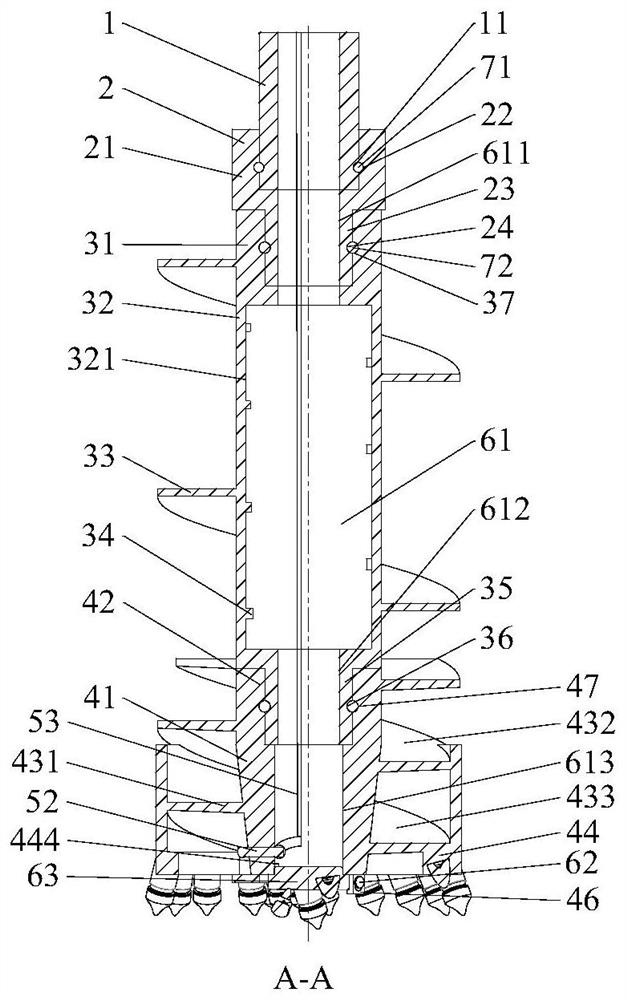

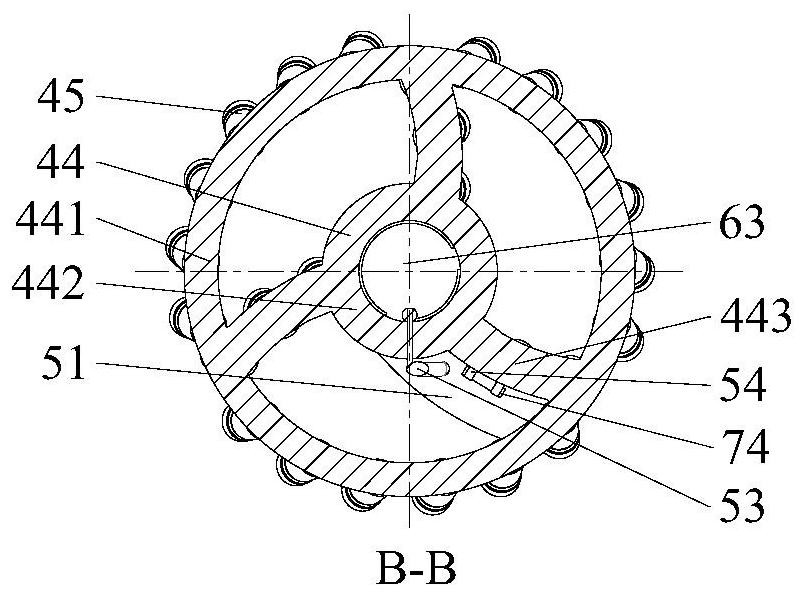

[0034] In the above-mentioned one embodiment, efficient drilling, synchronous chip removal, and continuous pouring are realized by using the power connector 2, the circulation device 3, the drill parts, the cleaning mechanism and the pouring mechanism. In this embodiment, the torque and bit pressure are transmitted through the power connector 2 and the circulation device 3, and the drill bit part 4 is driven to screw in, and the synchronization of chip removal is realized through the circulation device 3; when drilling into the geological formation that meets the requirements, The external control pushes the bottom cleaning cutter head 51 out by stretching the control member 52 to realize the removal of debris at the bottom of the well; after the bottom cleaning operation is completed, there is no need to replace the pouring equipment, and efficient continuous pouring operations are realized. When drilling normally, under the action of axial pressure and circumferential force, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com