Three-return-stroke powder heat conduction oil boiler

A heat-conducting oil boiler and three-pass technology, applied in steam boilers, fluid heaters, water tube steam boilers, etc., can solve the problems of high consumption of boiler steel and furnace wall materials, uneven combustion, and short flue gas flow, etc., to achieve Improve heat exchange efficiency, compact overall structure, and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

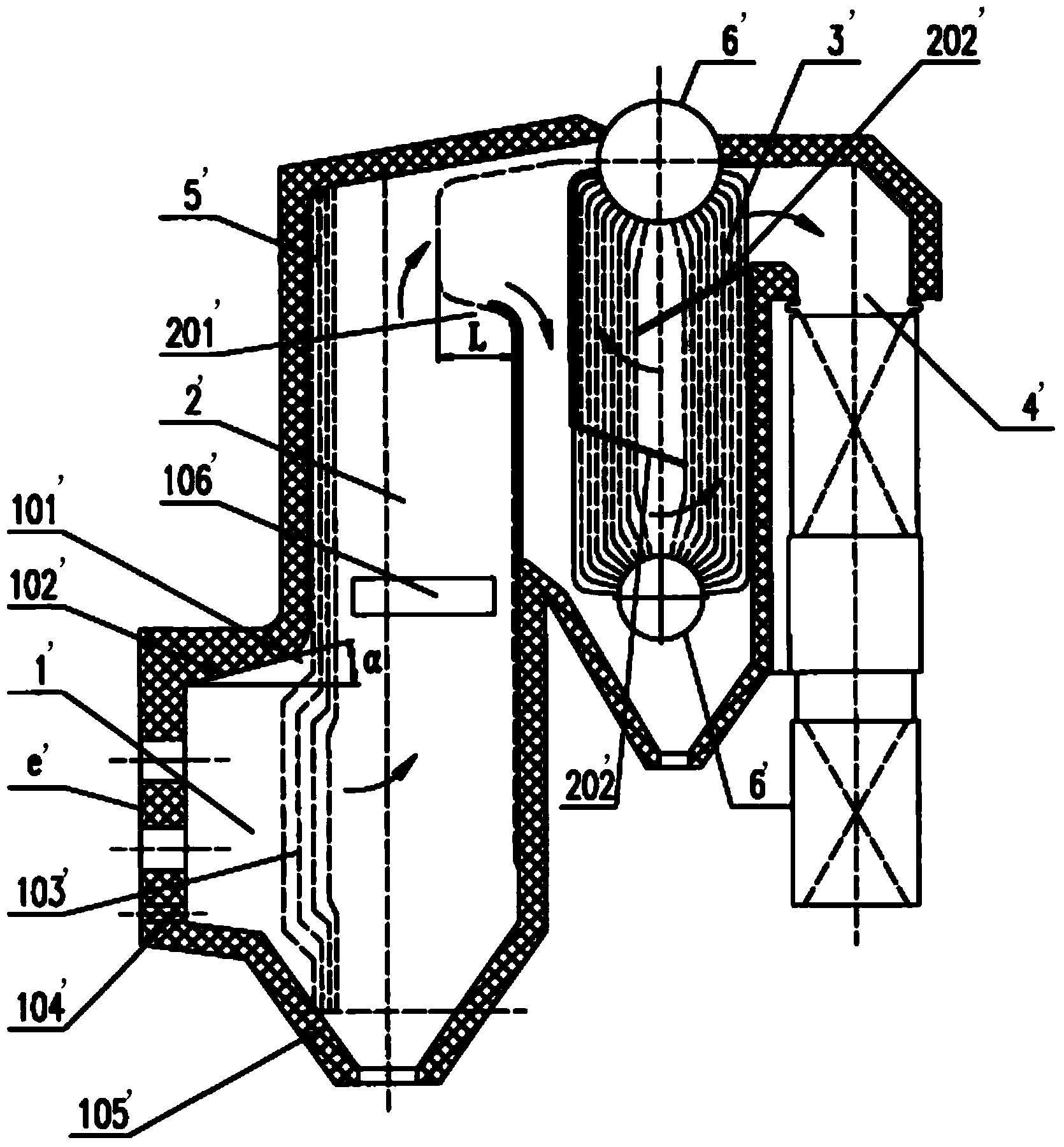

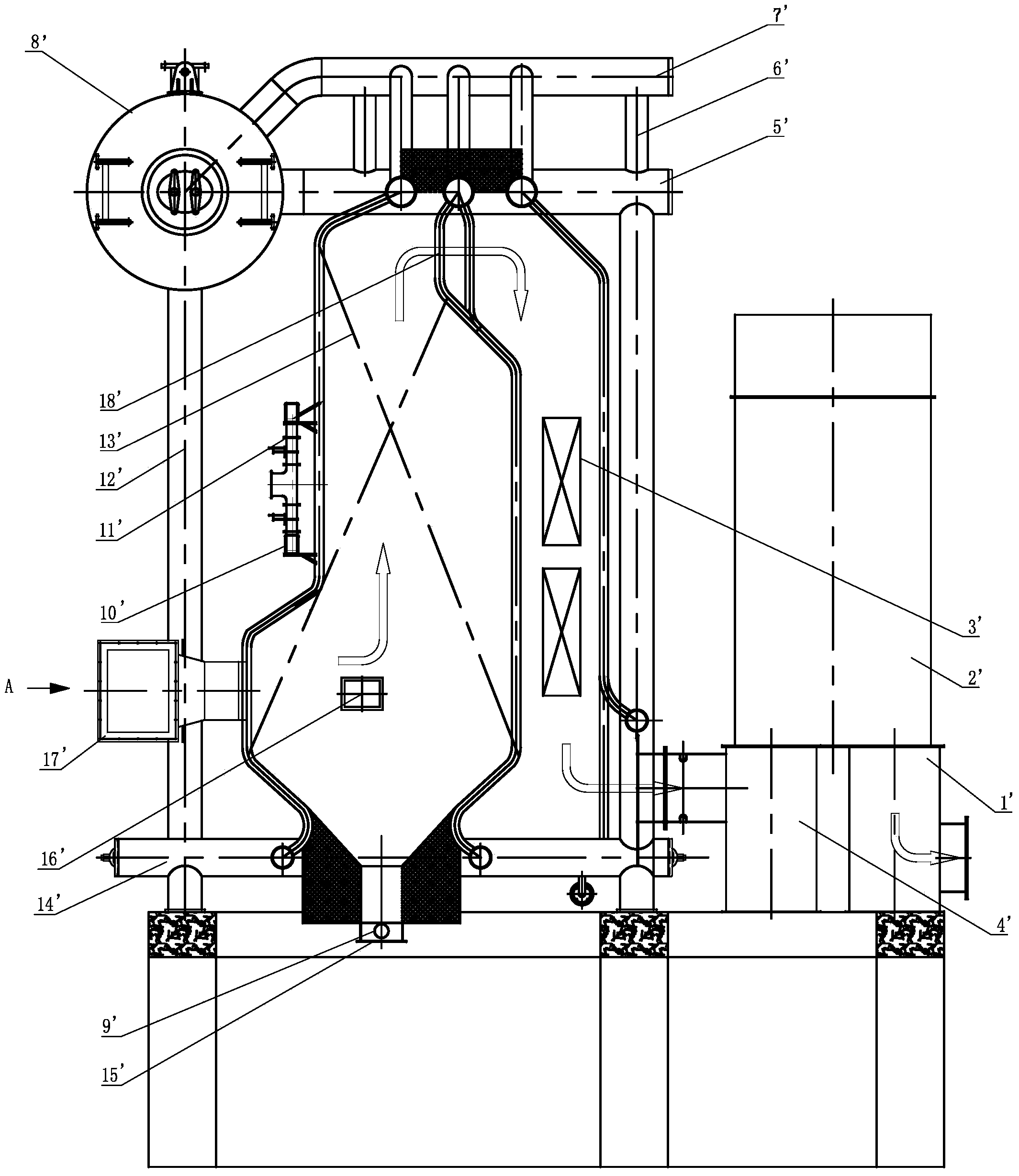

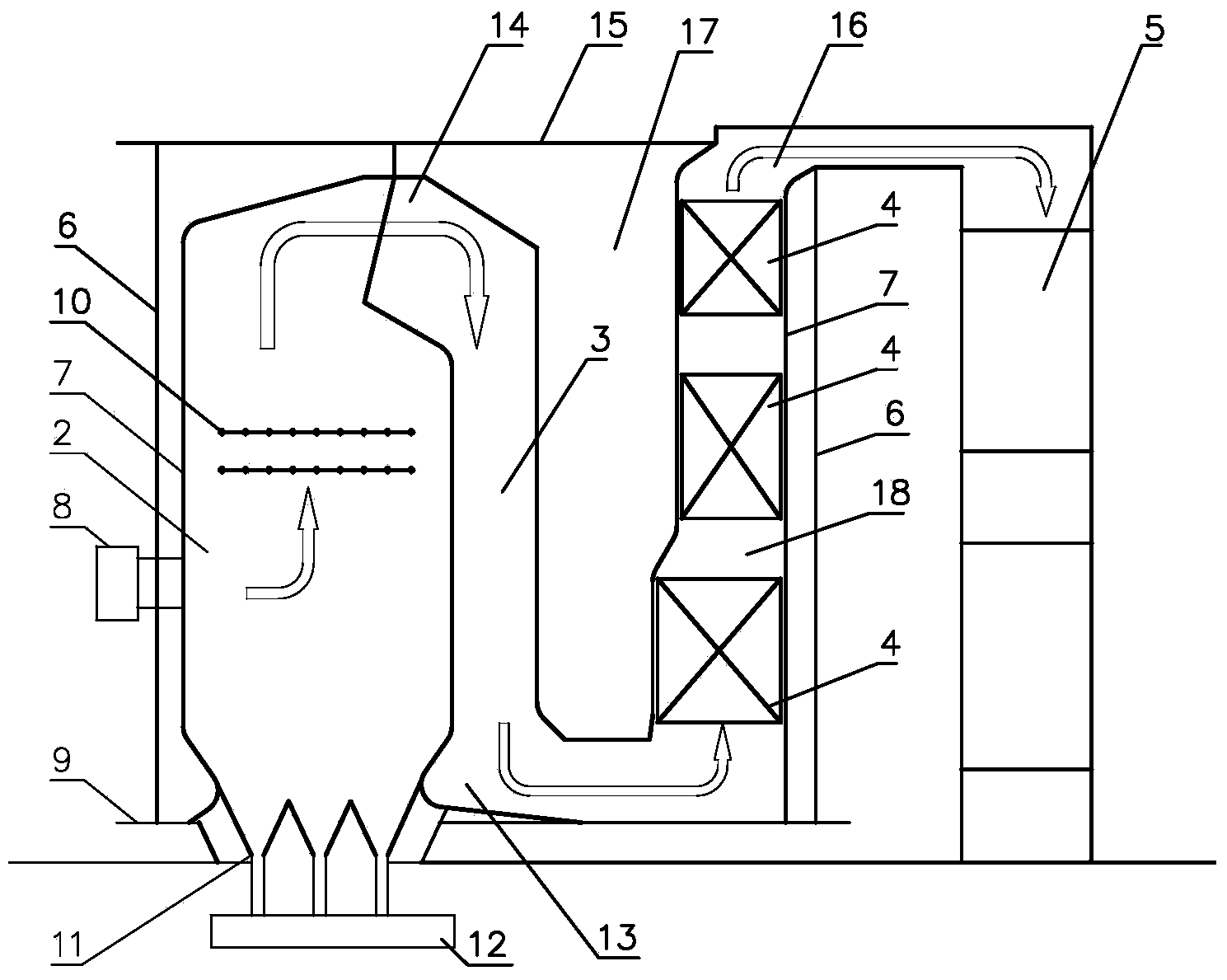

[0039] refer to image 3 , the first embodiment of the present invention. The boiler body includes circulating oil pump, furnace 2, burnout chamber 3, convection tube bundle 4, tail heat exchange equipment 5, burner 8, slag removal device 11, lower header 9 and upper header 15, the lower header 9 It is arranged at the bottom of the boiler body, and the upper header 15 is arranged on the top of the boiler body; the burner 8 is arranged at the front of the boiler furnace; Tube or tube frame structure, four main downcomers 6 are arranged at the four corners; the convection tube bundle 4 adopts a flag surface tube or a serpentine tube structure, and is arranged in a row in the convection tube bundle flue 18; the convection tube bundle The flue 18 is vertically arranged and is at the same height as the furnace 2; the upper and lower ends of the convection tube bundle 4, the main downcomer 6 and the membrane water wall 7 are connected to the upper header 15 and the lower header res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com