Package boiler of unitary construction

A quick-installed boiler and integral structure technology, applied in steam boilers, steam boiler accessories, water tube steam boilers, etc., can solve problems such as damage, leakage at the connection between the tube and the steam drum and water drum, device rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

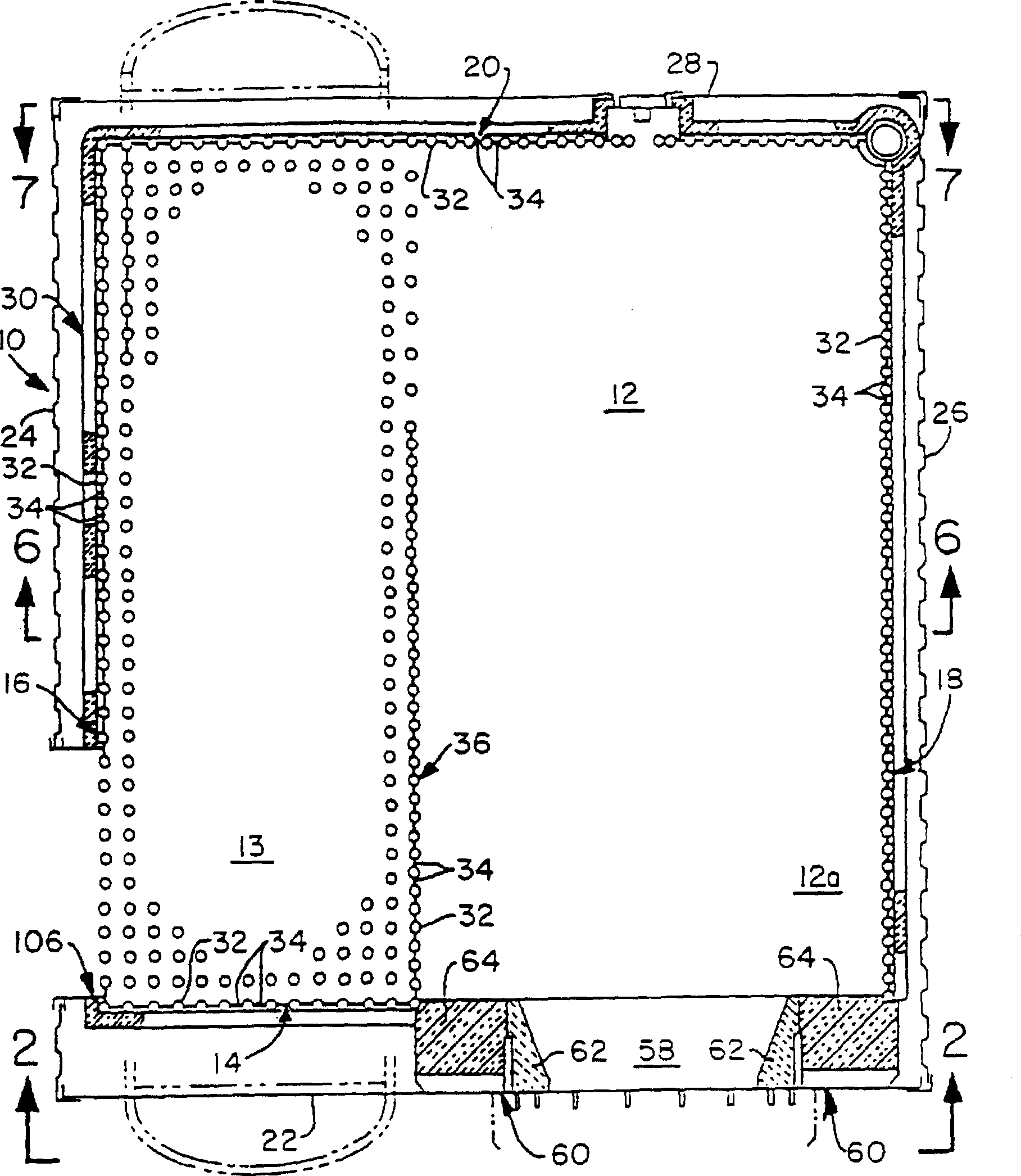

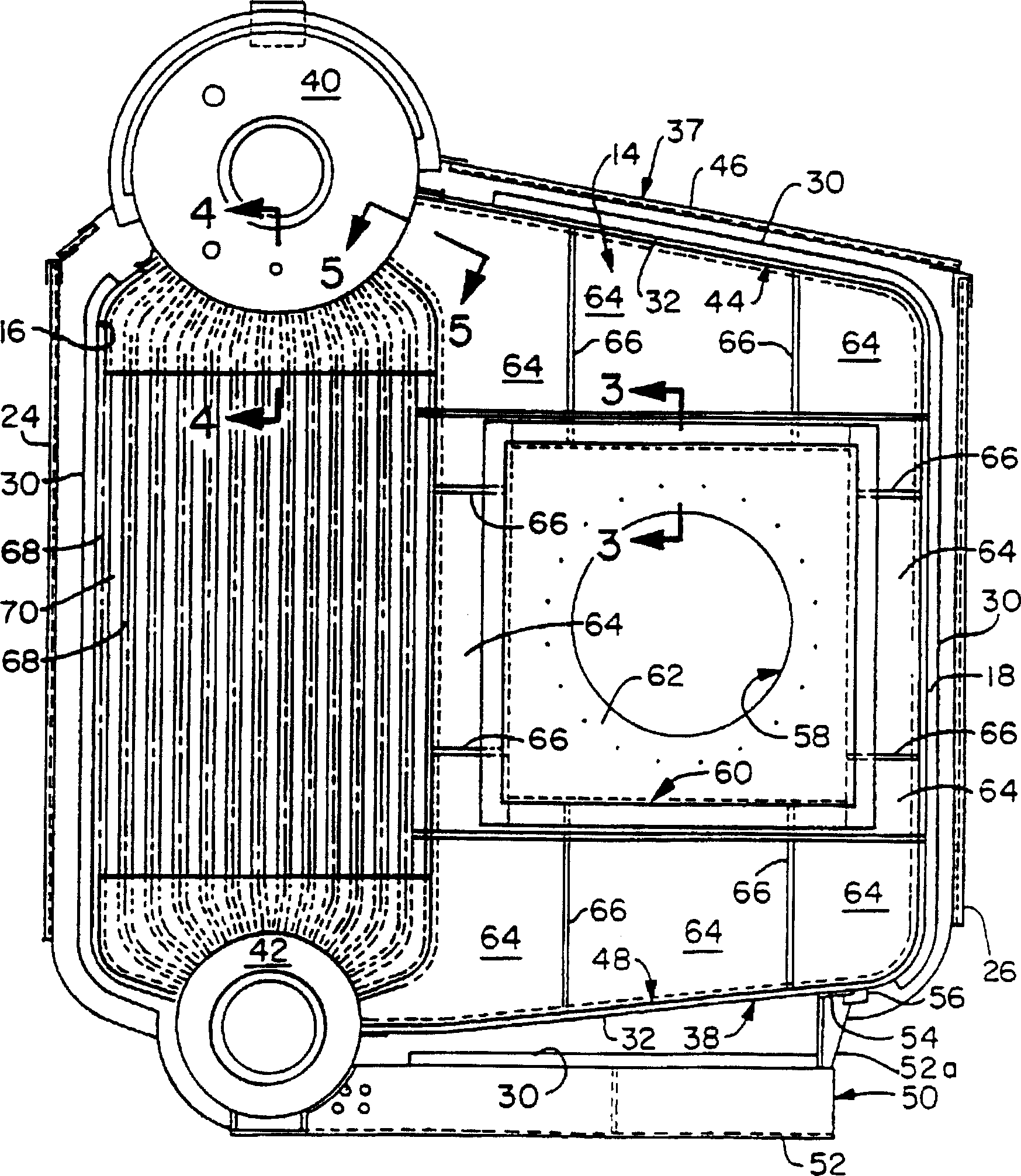

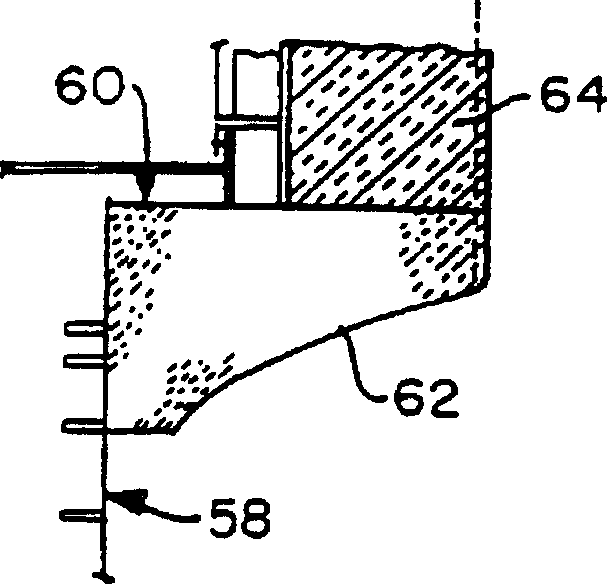

[0037] DESCRIPTION OF THE PREFERRED EMBODIMENT

[0038] Referring now to the accompanying drawings, in particular figure 1 , 2 , 6 and 7 to describe the package boiler of the present invention generally indicated by reference numeral 10. As can be fully understood with reference to the foregoing drawings and will be described in detail below, the ready-to-assemble boiler 10 is a unitary structure, that is, the boiler is designed so that it can be assembled into a unitary unit at the place of manufacture, and the boiler can be integrated thereafter. It can be transported from the place of manufacture to the place where the quick-pack boiler 10 needs to be used. In this regard, a package boiler 10 constructed in accordance with the present invention capable of producing 27,216-81,648 kg / hr (60,000 lb / hr-180,000 lb / hr) of steam is designed The package boiler 10, which produces 27,216 kg / hr (60,000 lb / hr) of steam, is designed to be transported in one piece by truck. For this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com