Biomass full-film type wall boiler

A membrane-type wall and biomass technology, which is applied to steam boilers, steam boiler accessories, water-tube steam boilers, etc., can solve the problems of flue gas fly ash leakage in the furnace, unstable gravity, wrong opening state, etc., to save manpower cost, reduce air leakage rate, and increase the effect of airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

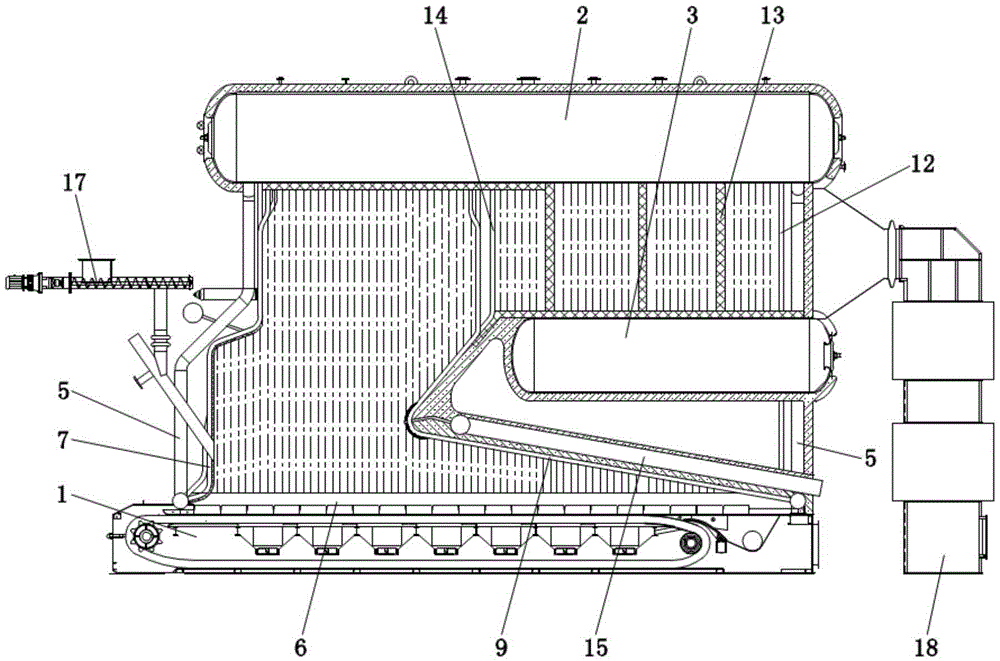

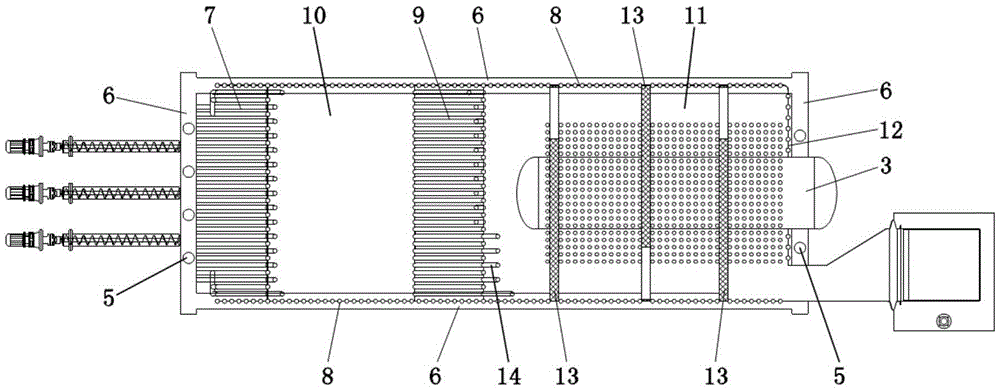

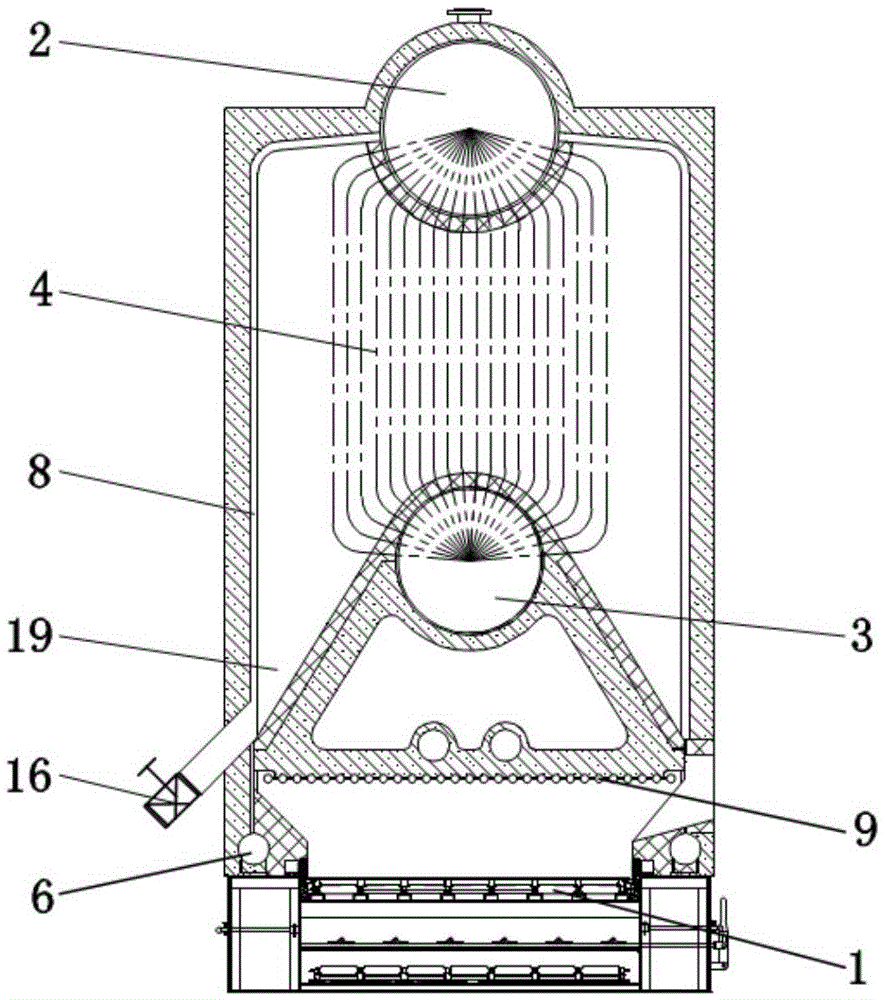

[0023] Such as figure 1 As shown, the biomass full-film wall boiler is composed of a boiler body, a feeding device 17 and an economizer 18 .

[0024] The main body of the boiler is composed of a chain grate 1, an upper drum 2, a lower drum 3, a convection tube bundle 4, various membrane walls, a downcomer 5 and a lower header 6.

[0025] Four lower headers 6 arranged horizontally are installed around the chain grate 1, and the four lower headers 6 communicate with each other to form an integrated annular header. The front end of the upper drum 2 is connected with four downcomers 5, the rear end of the upper drum 2 is connected with two downcomers 5, and the right end of the lower drum 3 is connected with two downcomers 5. The bottom ends of all downcomers 5 are inserted into the annular header.

[0026] The furnace 10 is surrounded by a chain grate 1 , an upper drum 2 , a front membrane wall 7 , two side membrane walls 8 and a rear arch membrane wall 9 . The front membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com