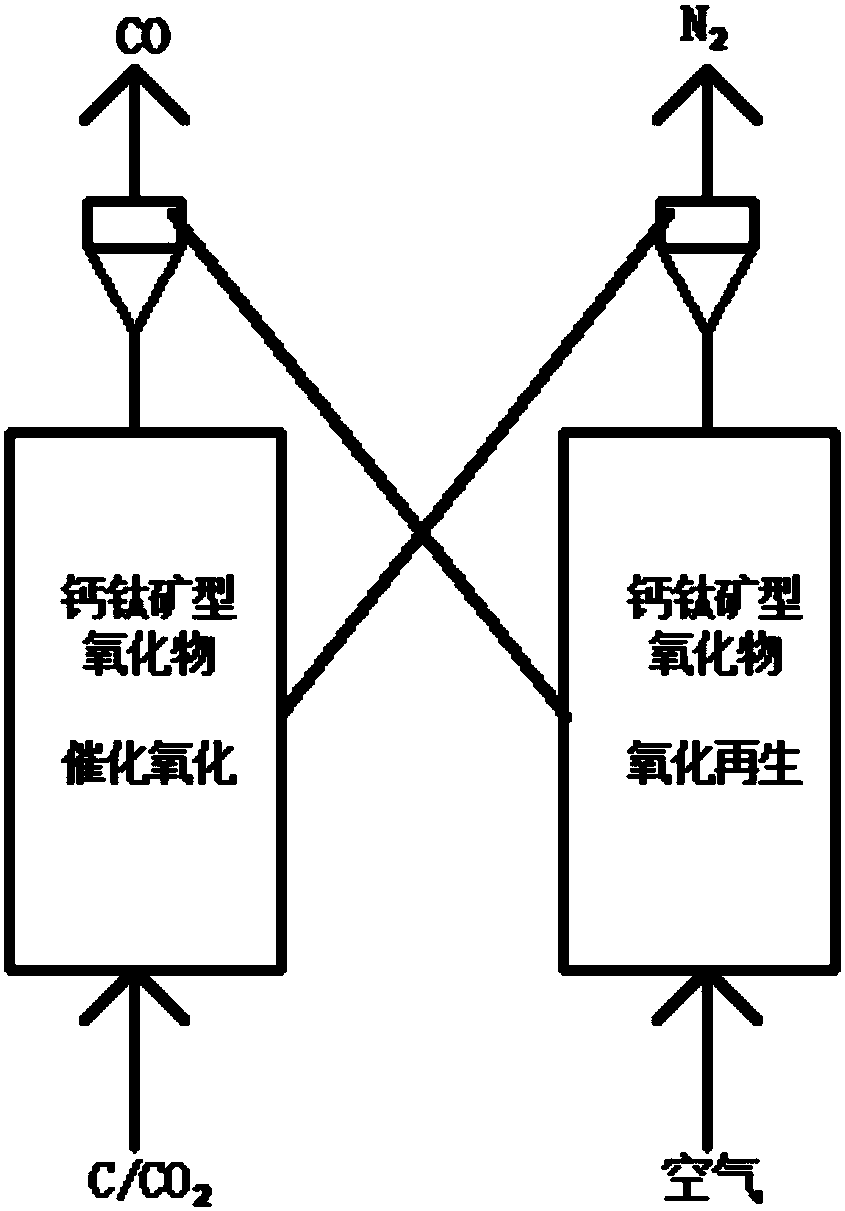

Method for catalyzing coke-carbon dioxide gasification based on chemical-looping principles

A carbon dioxide and chemical chain technology, applied in the field of coal gasification, can solve the problems of inability to recycle catalysts, affect gasification equipment, deactivation recovery rate, etc., and achieve the effect of not being volatile, improving recycling rate, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] As an embodiment of the present invention, the present invention selects perovskite as the catalyst of the gasification reaction. There are variable valence metals and oxygen vacancies in the crystal structure of the actual perovskite, and the reducing substance coal char can be combined with The adsorbed oxygen on the oxygen vacancies reacts with the lattice oxygen to strengthen the gasification reaction; while in the calcined air atmosphere, by capturing the oxygen in the air, the catalyst regenerates lattice oxygen and adsorbs oxygen to restore its structure, which can be sent again. Into the gasification furnace for gasification reaction, with good cycle performance.

[0027] In the coal char carbon dioxide catalytic gasification method of the present invention, the catalyst is preferably calcined in an air calciner at 700°C-900°C to recapture the oxygen in the air, so as to reduce the perovskite structure and realize recycling. In the coal char carbon dioxide catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com