A flip-down ring wax mold shooting device

A technology for wax molds and rings, which is applied in the field of flip-down ring wax mold dusting device, which can solve the problems of low efficiency, dust and human injury, etc., and achieve good results and prevent human injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

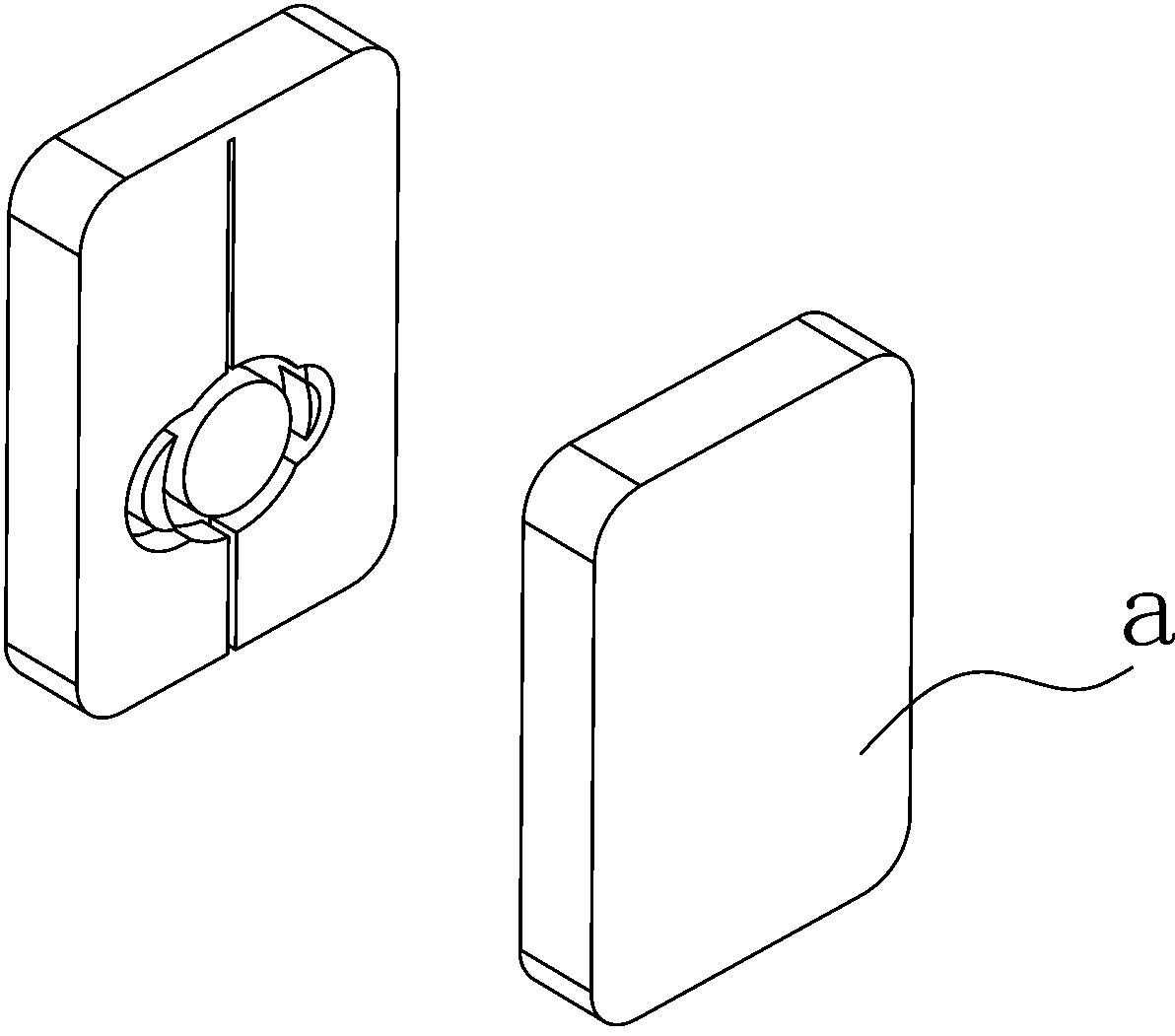

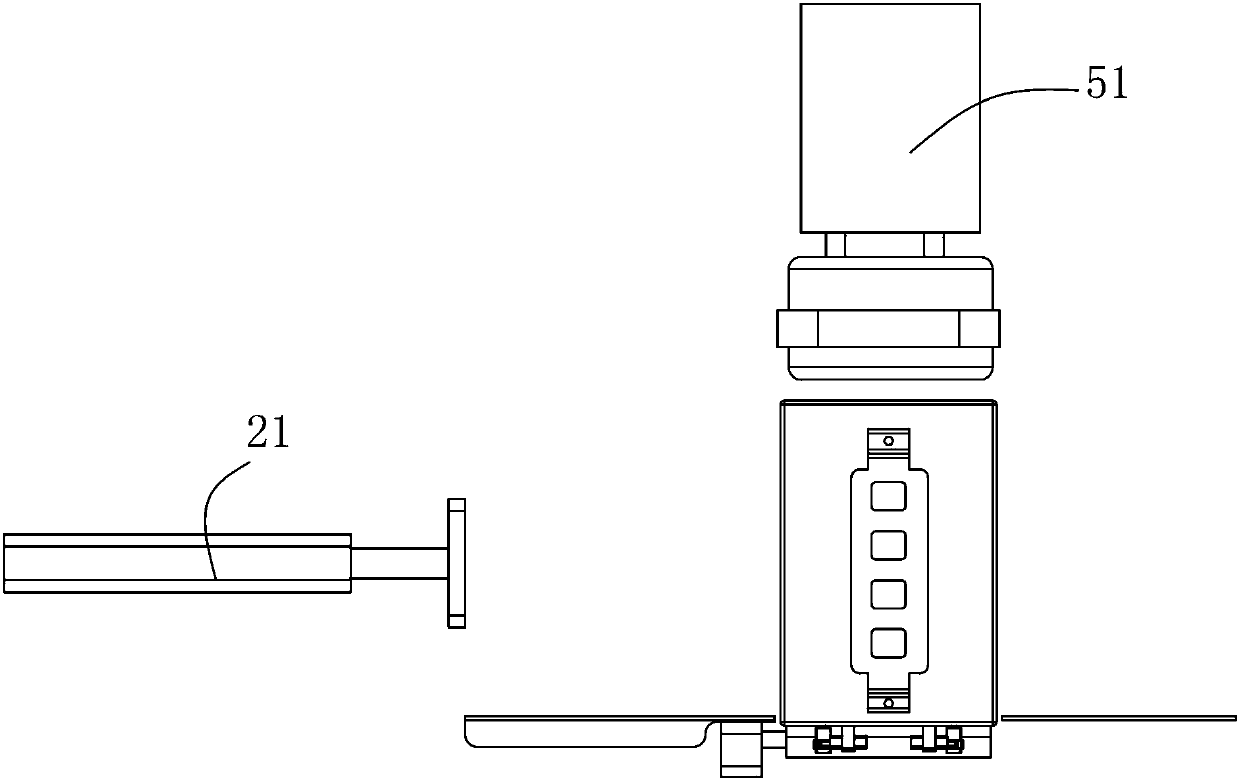

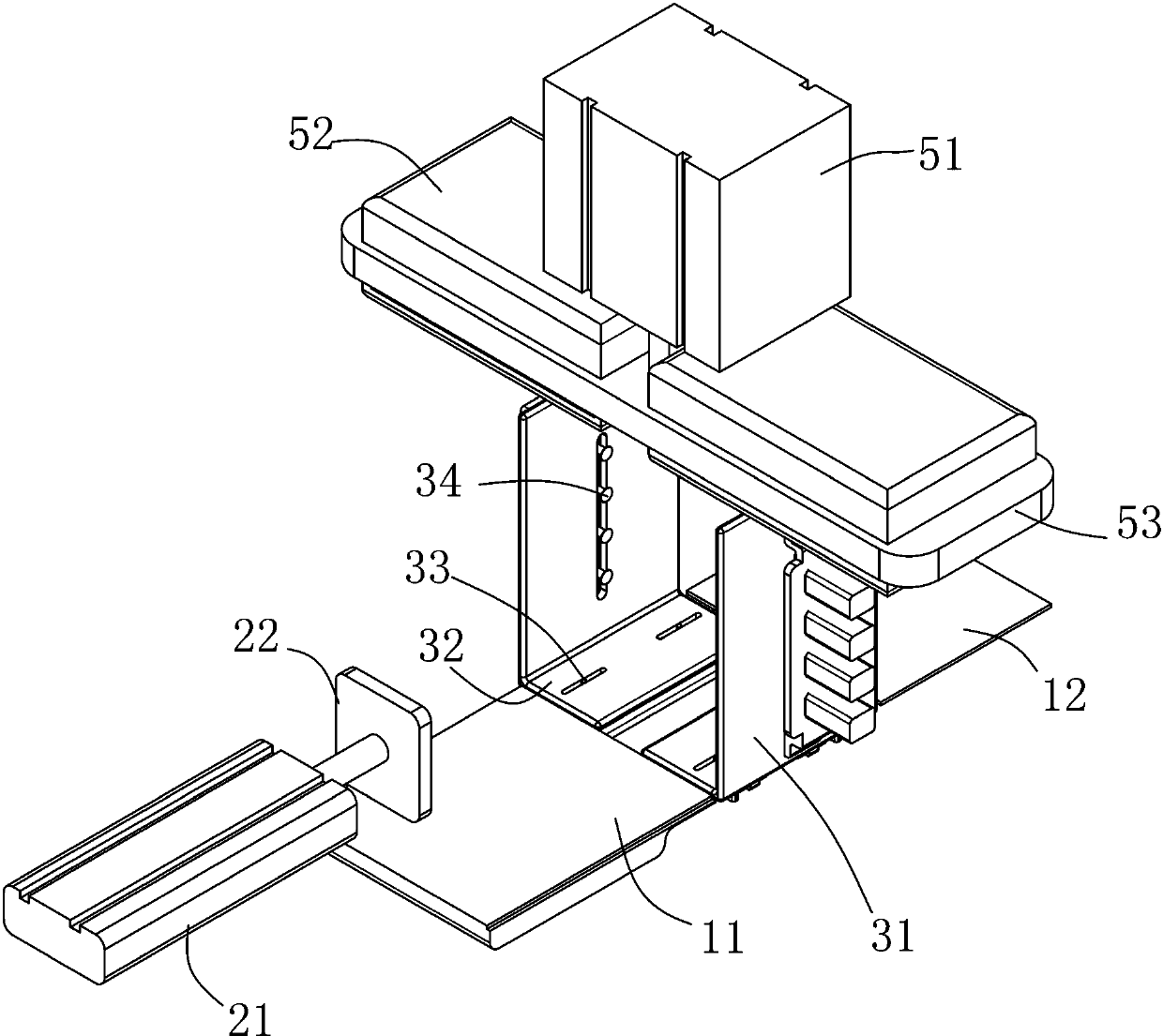

[0026] like Figure 1 to Figure 8 As shown, the downward-turning ring wax mold a powder-shooting device described in this embodiment includes a folding mechanism, a feeding tray 11 and a discharging tray 12 arranged on both sides of the folding mechanism, and also includes a push-out mechanism. Institutions and powder-shooting mechanisms for powder-shooting;

[0027] The push-out mechanism includes a push-out cylinder 21 and a push plate 22 located at the power output end of the push-out cylinder 21, and the feeding tray is located between the push-out mechanism and the folding mechanism;

[0028] The folding mechanism includes two L-shaped splints, each splint includes a short plate 32 and a long plate 31, and the short plate 32 is provided with four posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com