Automatic soup stewing and filling robot

A robot and soup stewing technology, which is applied in the field of robots, can solve the problems such as the difficulty of evenly distributing the soup and soup, the lack of soup, and the difficulty of controlling the soup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

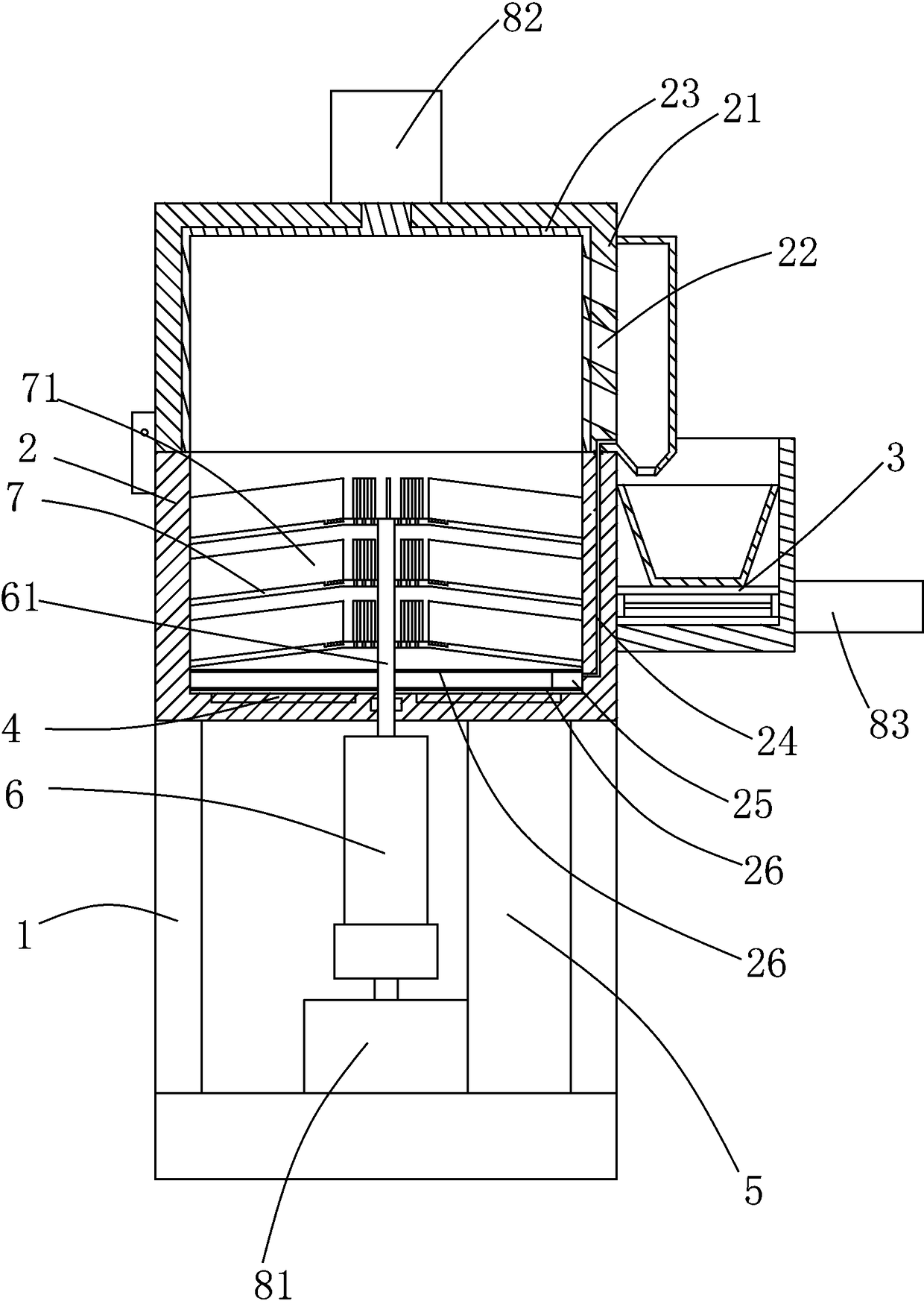

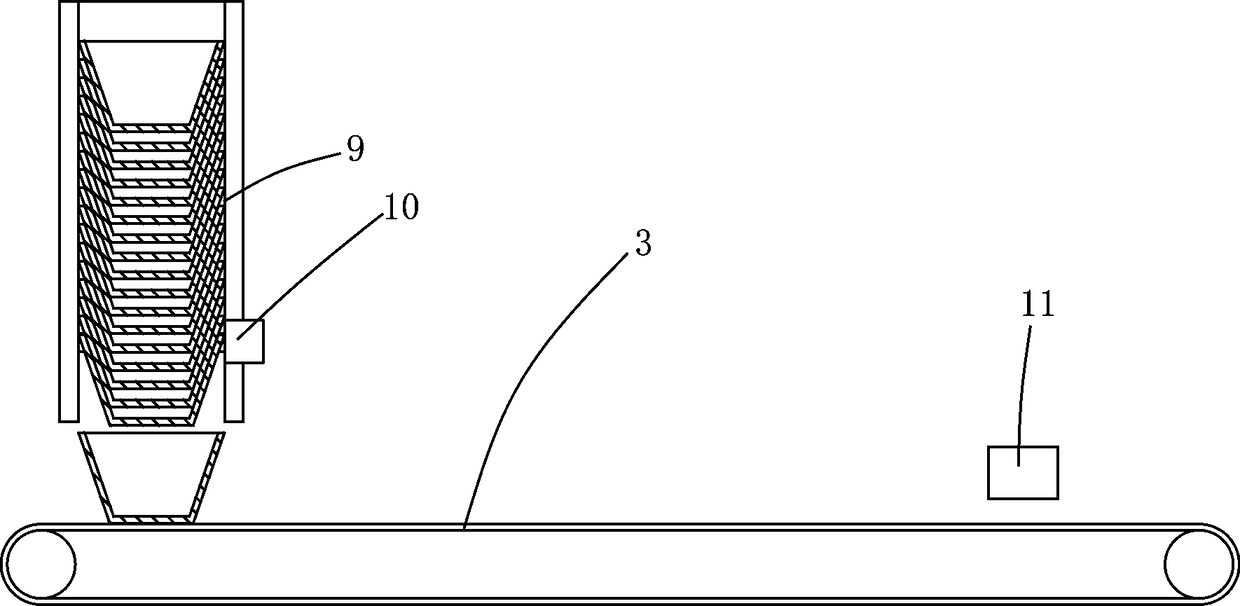

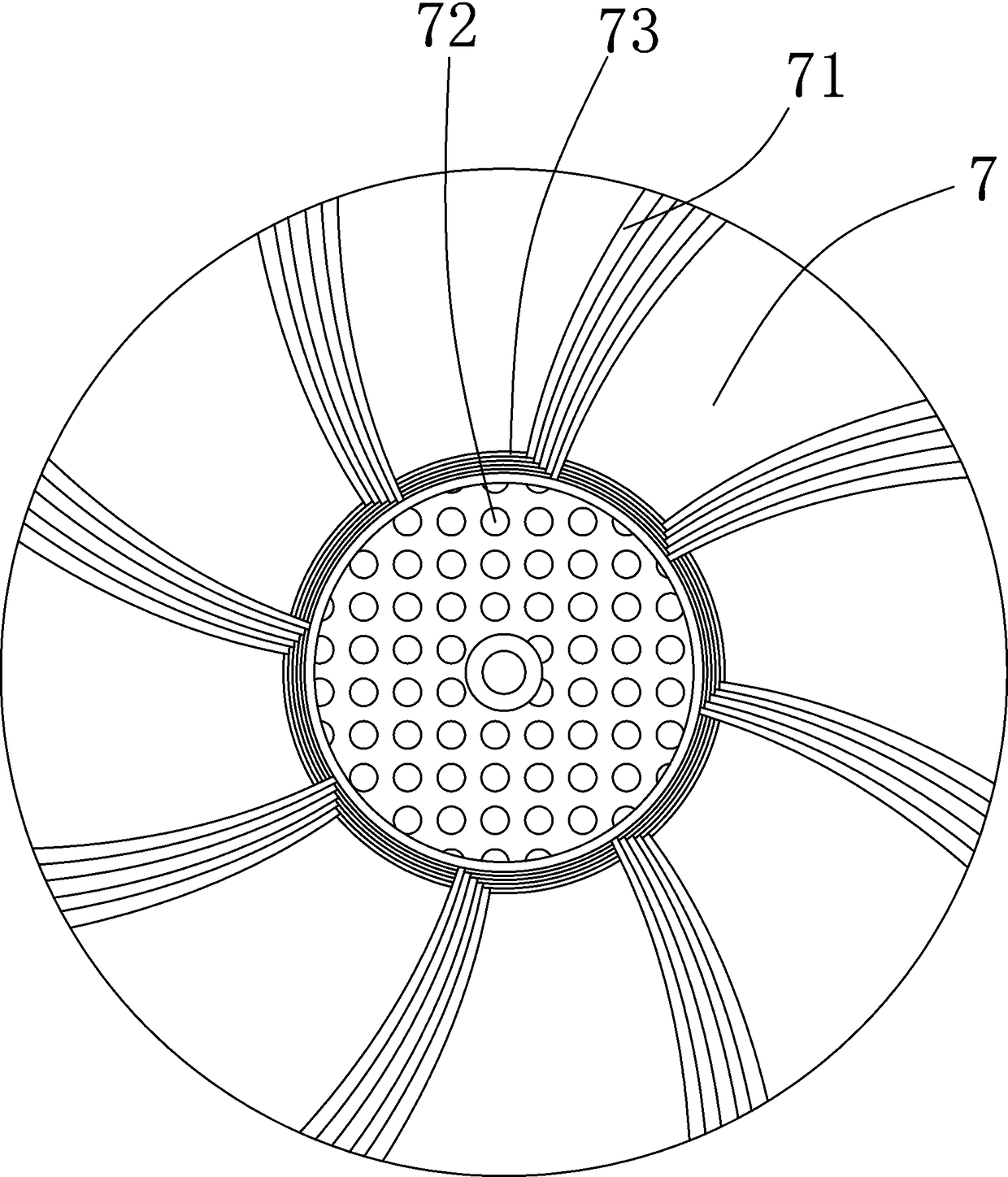

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 6 , an automatic soup stewing robot, including a support 1, a cylindrical stew pot 2, a conveyor belt 3, a heating device 4 and a control device 5, the bottom of the stew pot 2 is provided with an electric push rod 6, and the electric push rod The telescopic rod 61 of 6 extends into the bottom of the stewing pot 2, and the telescopic rod 61 is provided with some partitions 7, and the upper surfaces of some of the partitions 7 are uniformly provided with some railings extending outward along the center of the partition 7 71, the middle part of the partition 7 gradually slopes outward, the middle part of the partition 7 is provided with a through hole 72, the bottom of the electric push rod 6 is provided with a first motor 81, and the top of the stew pot 2 is hinged with a pot Cover 21, the pot cover 21 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com