A hydrolysis ammonia supply and denitrification system for power plants and its control method

A technology for ammonia supply and denitrification, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of fluctuation, unstable ammonia gas fluctuation, improper control methods, etc., and achieves low power consumption, high desulfurization rate, and energy saving. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

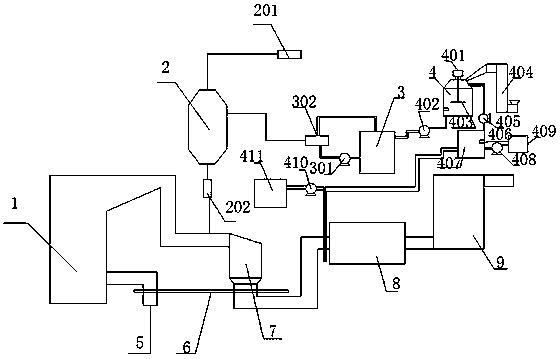

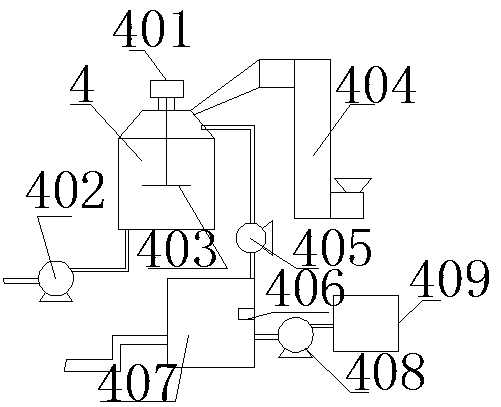

[0037] As shown in the figure, the specific implementation method is as follows:

[0038]A hydrolysis ammonia denitrification system used in a power plant, comprising an SCR reactor 7 and a dust collector 8 serially connected in series on the gas outlet pipeline of a boiler 1, and an air preheater is installed on the pipeline connected between the SCR reactor 7 and the dust collector 8. Heater 6, the pipeline of the air supply inlet 5 of the boiler 1 is connected with the air preheater 6 so as to preheat the air entering the boiler 1 by using the waste heat of the exhaust gas of the boiler 1, and also includes a controller for controlling the automatic operation of the whole system, The ammonia injection grid in the SCR reactor 7 is connected to the hydrolyzer 2, and the pipeline connected to the ammonia injection grid and the hydrolyzer 2 is provided with an adjustment module 202 for controlling the amount of ammonia gas fed into the hydrolyzer. The adjustment module 202 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com