On-line measurement method and system for bar negative deviation

A measurement method and measurement system technology, which is applied in the field of steel rolling, can solve the problems of large negative deviation control lag and poor accuracy, and achieve the effect of reducing requirements and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

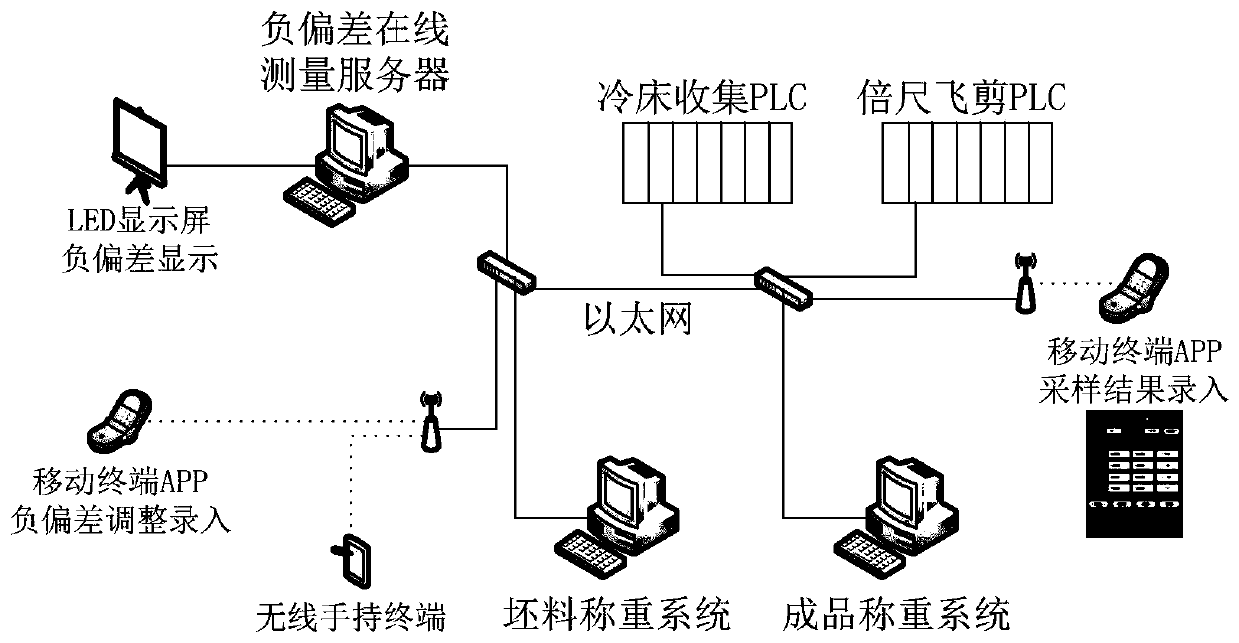

[0045] Such as figure 1 As shown, the bar negative deviation online measurement method of the present invention is used for bar and rebar negative deviation measurement, and the method includes:

[0046] Step A: Measure the actual weight value W of the billet at the entrance of the rolling mill Act , the unit is Kg; W Act It is the weighing value before being out of the furnace / rolling; this value can be obtained by weighing measurement before entering the furnace or out of the furnace or before rolling; the weighing out of the furnace can also be obtained by multiplying the length of the billet by the section and converting the specific gravity into weight;

[0047] Step B: Measure the actual total length L of the finished bar Act , the unit is m;

[0048] Step C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com