Onsite electric testing method for important mechanical parameters of friction type elevator system

A technology of mechanical parameters and hoists, applied in the direction of elevators, transportation and packaging, etc., can solve problems such as weighing and testing of huge mass and moment of inertia, potential safety hazards of the lifting system, and whether there are discrepancies in design parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

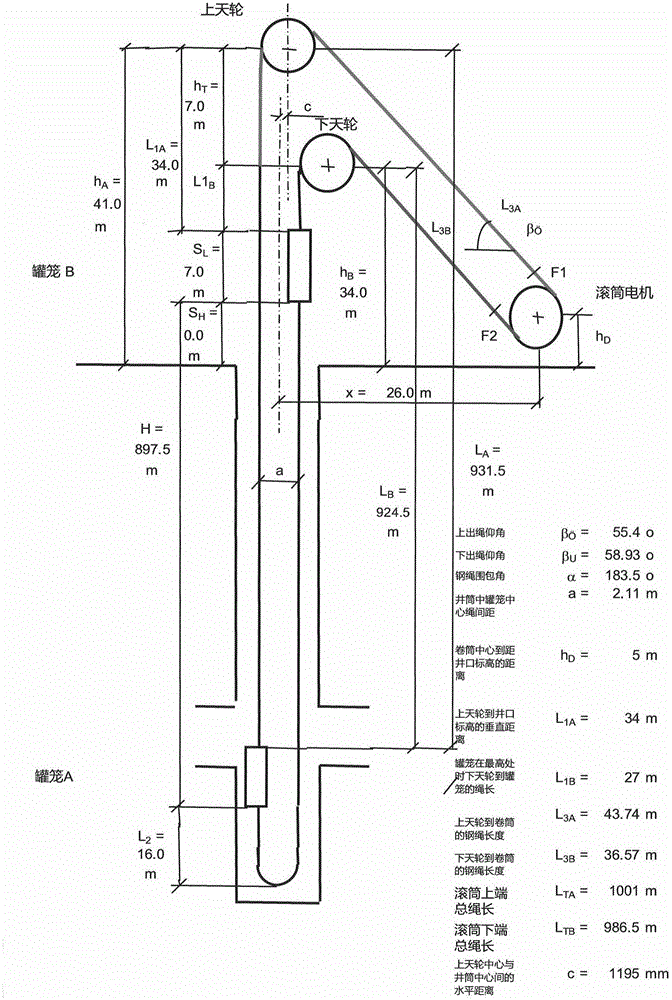

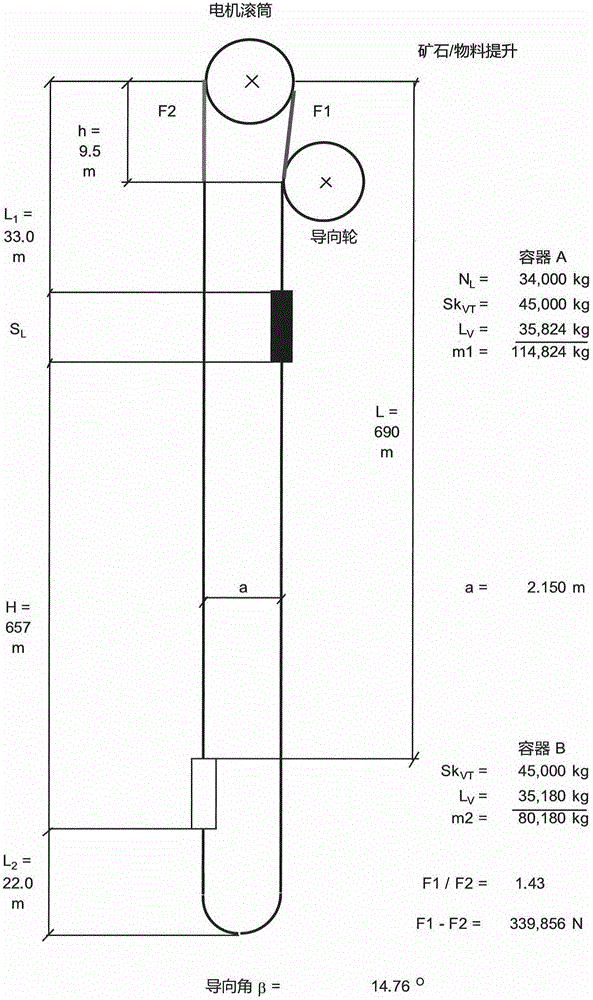

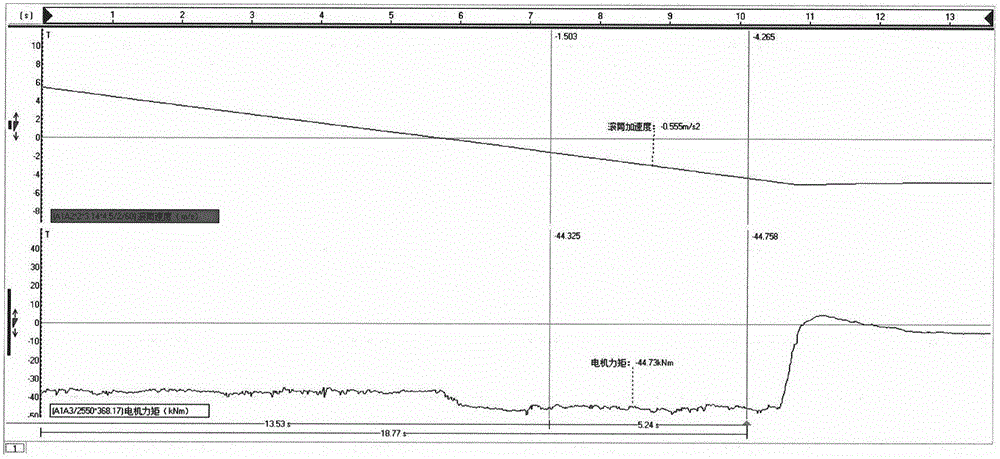

[0005] The present invention provides an automatic control system and an electric transmission system using a friction hoist, through precise control to make the hoist run under a specific working condition, record parameters such as motor torque, drum speed, and running displacement, and calculate the hoist The main mechanical parameters of the system. It is characterized in that: firstly, when the hoist is not hung with a rope, its motor and drum are assembled together, through precise control of the electric drive system of the motor, the motor and drum are accelerated to the rated speed of the hoisting system at a constant acceleration, and the motor torque and drum speed are recorded , use the formula to calculate the sum of the moment of inertia of the motor and the drum; after hanging the rope, the hoist runs back and forth between the bottom of the well and the wellhead at the rated lifting speed with no load, and records the torque of the motor, the speed of the drum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com