Full-suspension vibration avoiding type full-automatic washer dryer combo

A washing-extractor and full-suspension technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the complex operation of the shock-absorbing structure of the washing-and-washing machine, the small vibration of the washing-and-washing machine, and the inconvenience of installation Installation and other issues, to achieve the effect of enhanced elasticity, simple shock absorption, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

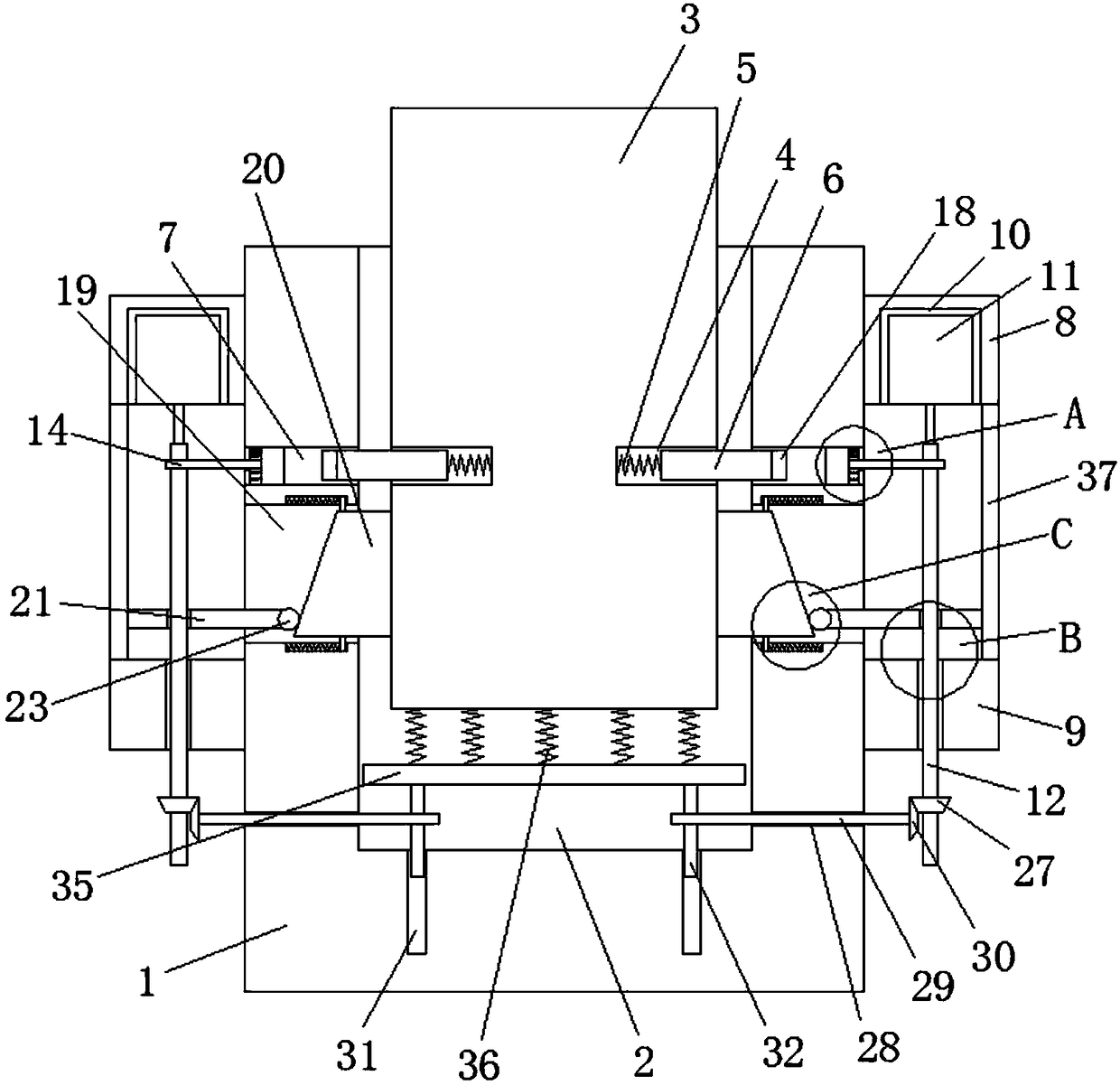

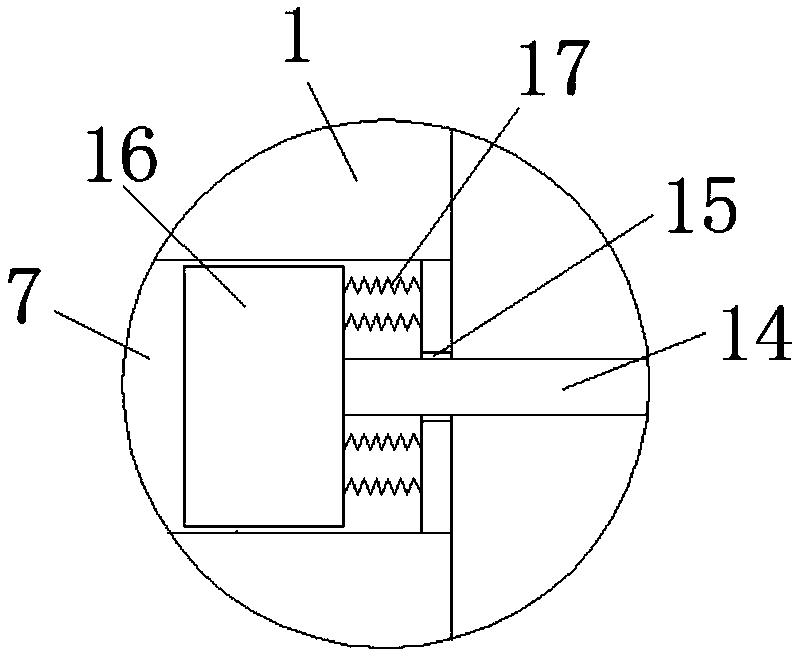

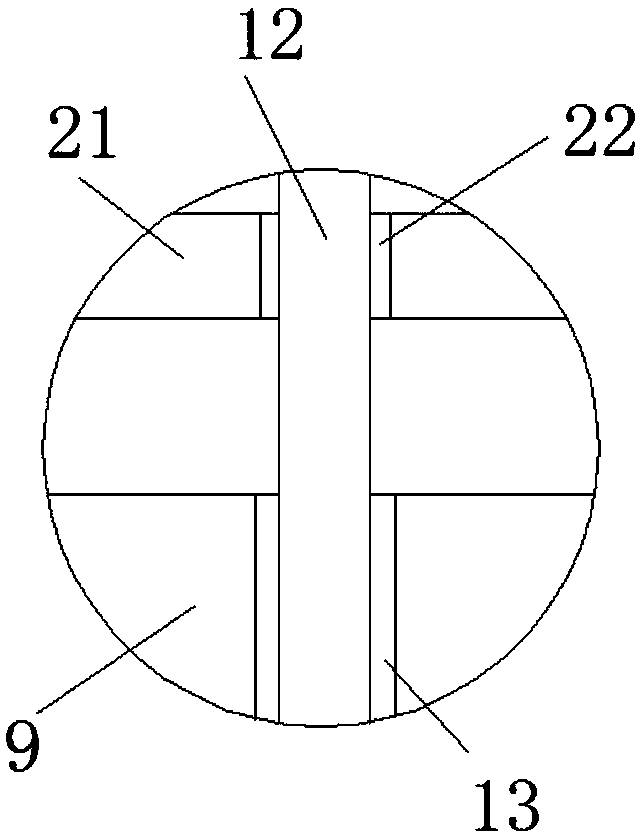

[0026] Reference Figure 1-5 In this embodiment, a full suspension vibration-proof automatic washing machine is proposed, which includes a mounting seat 1 and a first mounting groove 2 opened on the top of the mounting groove 1, and the washing machine body is installed in the first mounting groove 2 3. Both sides of the washing machine body 3 are provided with first sliding grooves 4, the inner walls of the two first sliding grooves 4 close to each other are welded with first springs 5, and the two first springs 5 are far away from each other. A first sliding plate 6 is welded at one end, and second sliding grooves 7 are provided on the inner walls of both sides of the first mounting groove 2. The sides of the two first sliding plates 6 far away from each other extend to the corresponding second sliding plates. A second magnet 18 is fixedly installed in the slot 7, a first fixing plate 8 is welded on both sides of the mounting base 1, and a second fixing plate 9 located belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com