Hydraulic leakage-proof control device

A control device and leak-proof technology, which is applied in fluid pressure actuation devices, fluid pressure actuation system testing, mechanical equipment, etc., can solve problems such as unsuitable harsh environments, equipment accidents, and high investment in large hydraulic equipment, and achieve significant Economic benefits, small scope, easy to find and handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

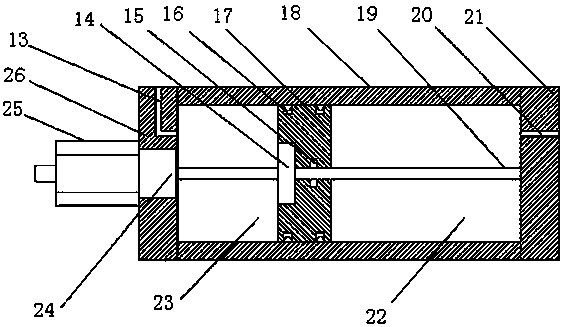

[0020] The invention includes a monitoring working part and an auxiliary part. The leakage preventer in the monitoring working part is used to monitor the amount of hydraulic oil in the hydraulic cylinder. When the hydraulic cylinder leaks, the monitoring working part will automatically cut off the connection between the hydraulic cylinder and the entire hydraulic system, so that the scope of the oil leakage accident will not expand. , Avoid hydraulic system shutdown and paralysis. The role of the auxiliary part is: to fill the leak preventer and the oil cylinder after the initial installation of the leak preventer; to replenish oil after the oil leakage of the pipeline or oil cylinder; to be a backup control system in case of emergency.

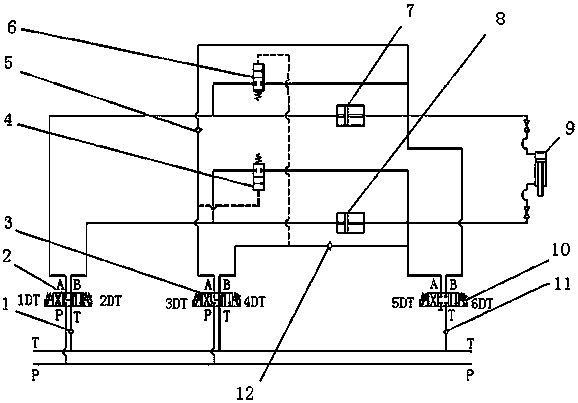

[0021] figure 1 It is shown that the monitoring work part is composed of the first one-way valve 1, the first three-position four-way reversing valve 2, the first leak preventer 7, and the second leak preventer 8. One external port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com