An automobile engine low pressure simulation tester

A technology for automobile engine and simulation testing, which is applied in the direction of internal combustion engine testing, etc., can solve the problems of high cost of low-pressure laboratory construction, maintenance and use, complex low-pressure simulation tester equipment, and long construction period, etc. The effect of stability, simple structure, and uniform air intake density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present application are clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

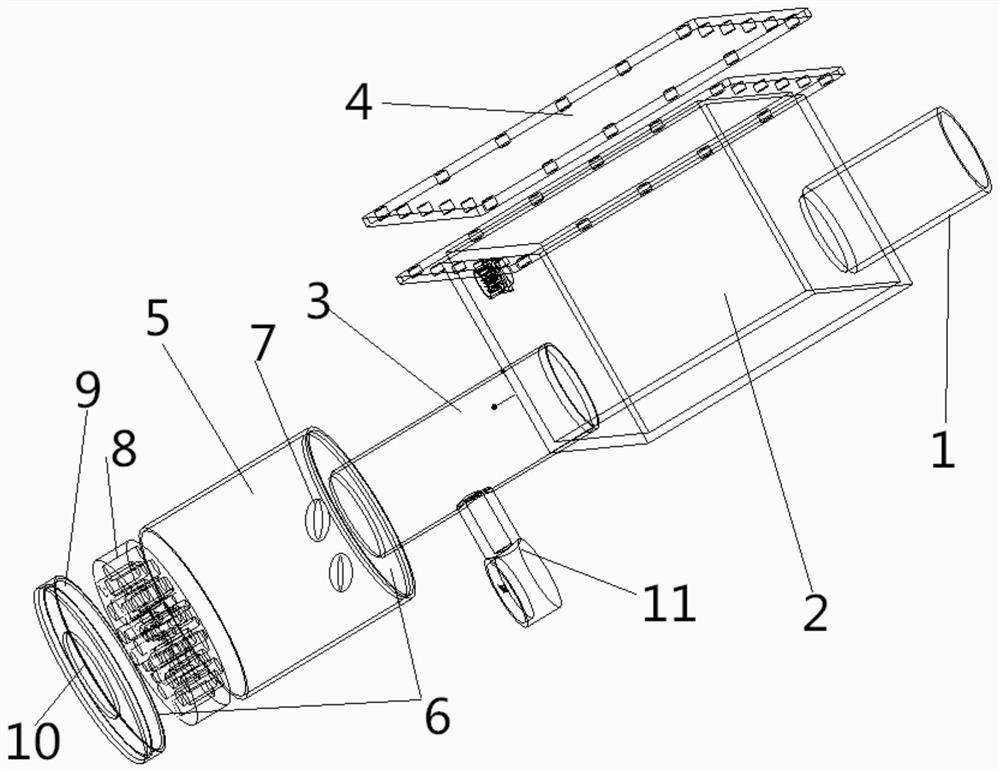

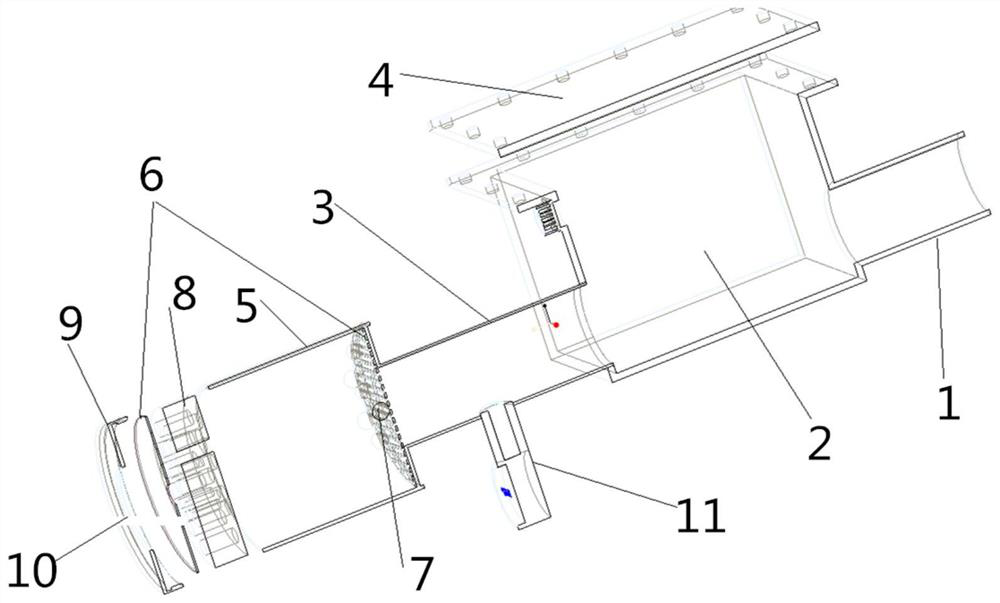

[0030] Such as figure 1 with figure 2 As shown, the present invention provides a low air pressure simulation tester for an automobile engine, which includes a control chamber 5, a pressure measuring piece 3 and a simulation chamber 2 sequentially connected in the direction from the air intake to the air outlet. The air outlet end of the simulation chamber 2 is provided with an air outlet pipe 1, and the air outlet pipe 1 is connected with the air inlet of the engine; the simulation chamber 2 is provided with a simulation chamber sealing cover 4, and the sealing cover 4 is fixed by screws, and has good sealing performance , before the test, the parts that need to be put into the simulation chamber 2 can be put in by opening the sealing cover 4 .

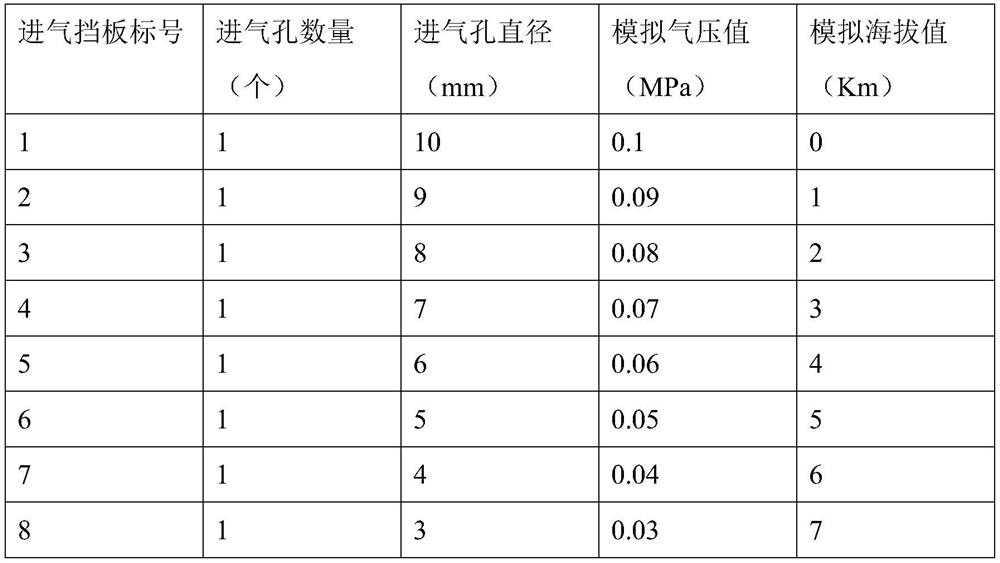

[0031] The air inlet end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com