High-altitude test clamp for deformation of transformer winding

A technology of transformer winding and high-altitude test, applied in the direction of measuring device casing, etc., can solve the problems of increasing operation safety risks, consuming manpower, material and financial resources, etc., and achieving the effect of avoiding high-altitude operations, increasing safety, and facilitating operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

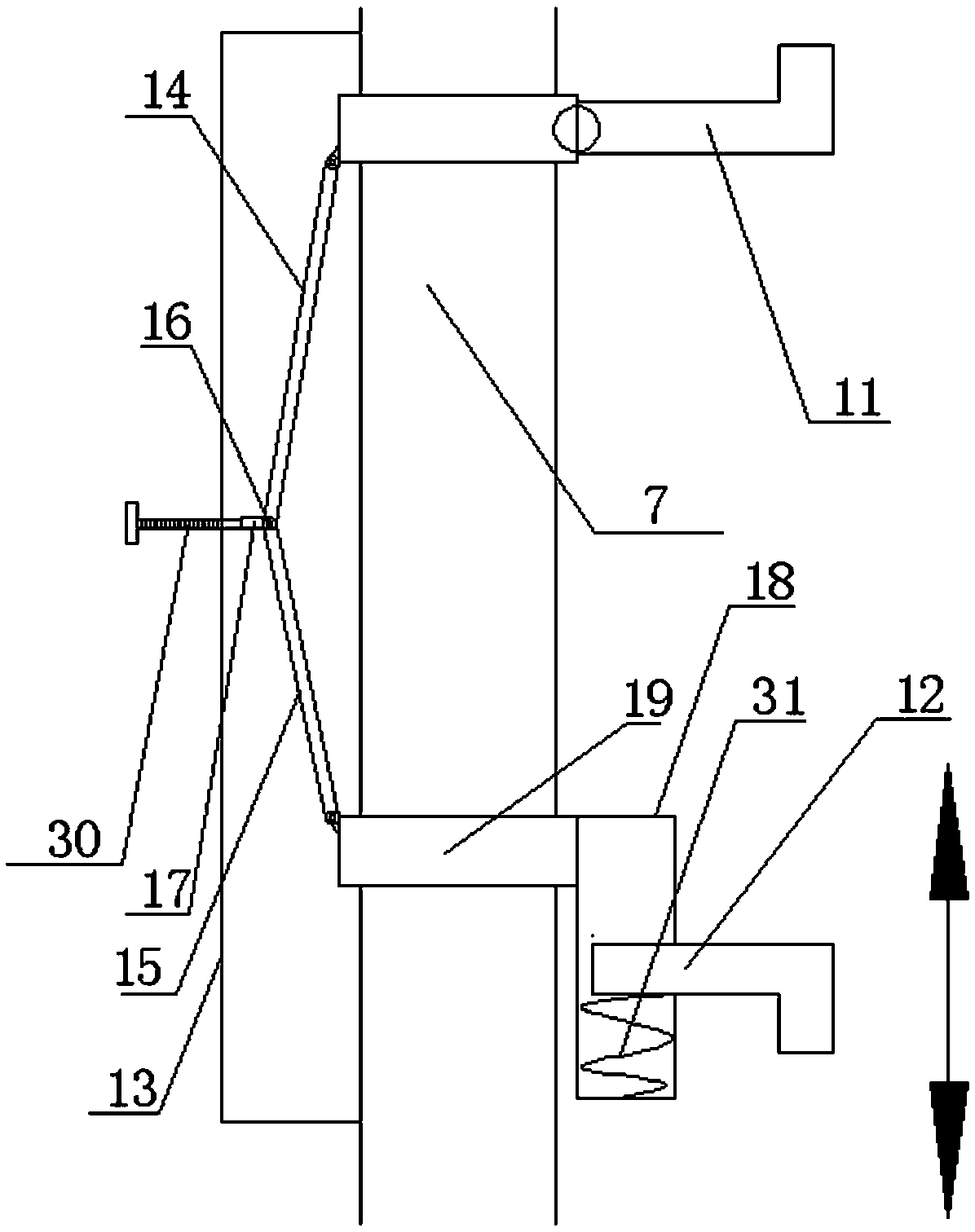

[0036] The present invention will be further described below in conjunction with accompanying drawing:

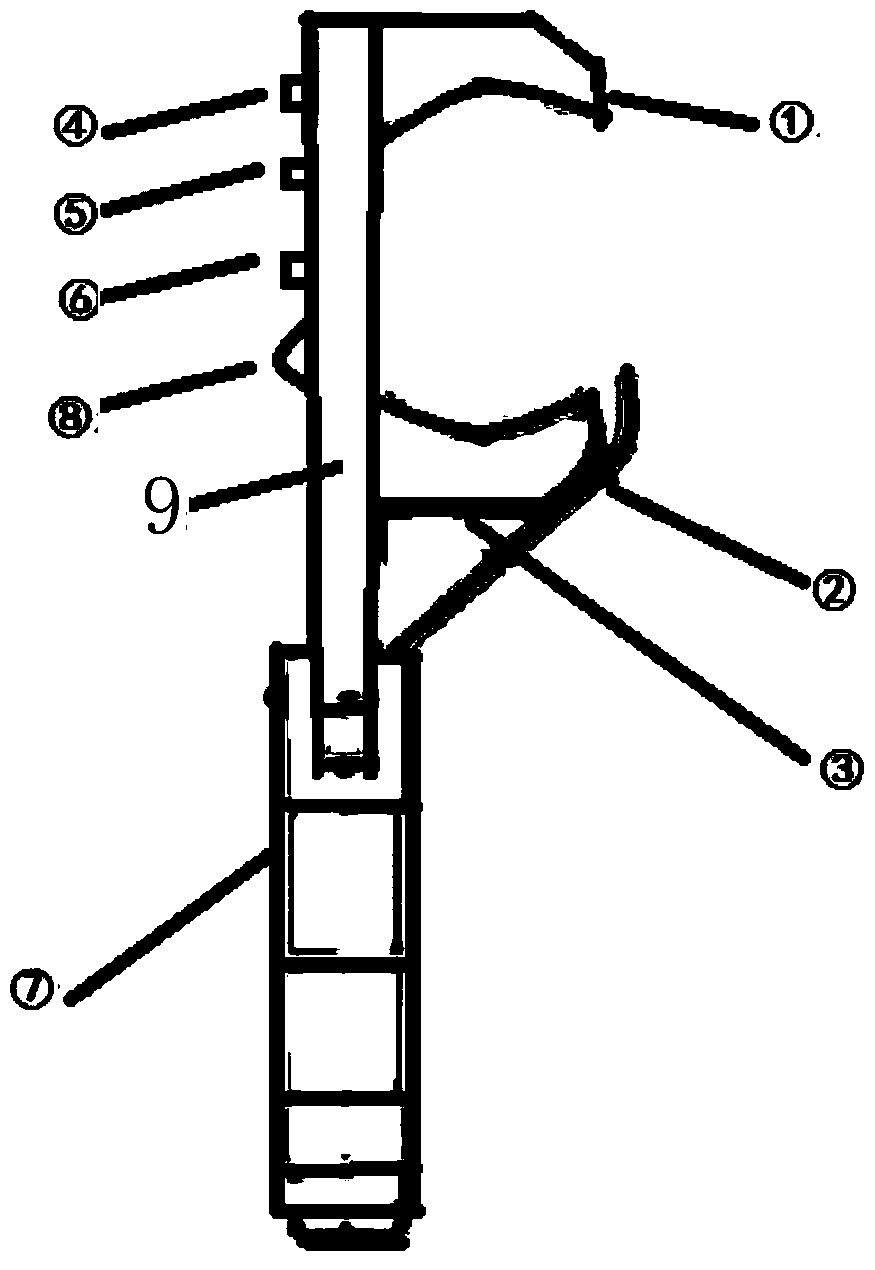

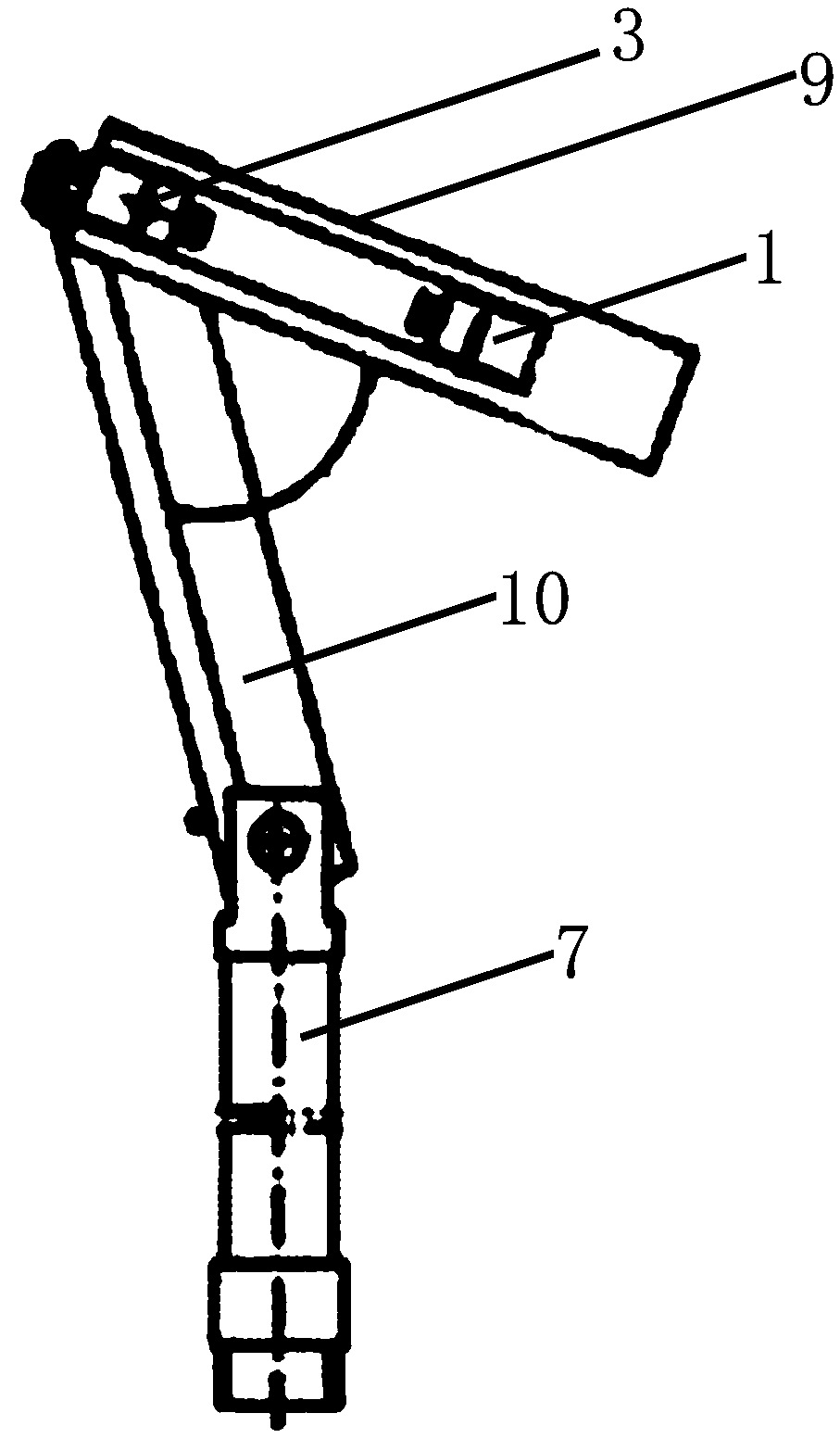

[0037] Such as figure 1 As shown, the present invention provides a special wiring pliers for transformer winding deformation high-altitude test based on the frequency response method. The wiring pliers include: upper jaw, lower jaw, guide rod, BNC signal terminal, BNC input terminal, shielding terminal, insulation Joystick.

[0038] The special-purpose wiring pliers are equipped with a BNC connector on its upper part.

[0039] The upper and lower jaws of the wiring pliers are connected by pulleys.

[0040] The guide rod adopts buckle mode.

[0041] The shielding end adopts a screw rod, and the shielding wire is fixed by a nut.

[0042] The insulating operating rod is made of resin material.

[0043]The transformer winding deformation high-altitude test clamp is characterized in that the test clamp includes a clamp head composed of an upper jaw (1) and a lower jaw (3), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com