Method for producing a hose connector with a pressure gauge for a pressure sensor

A pressure sensor, hose connector technology, applied in the direction of hose connection devices, pipes/fittings/fittings, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

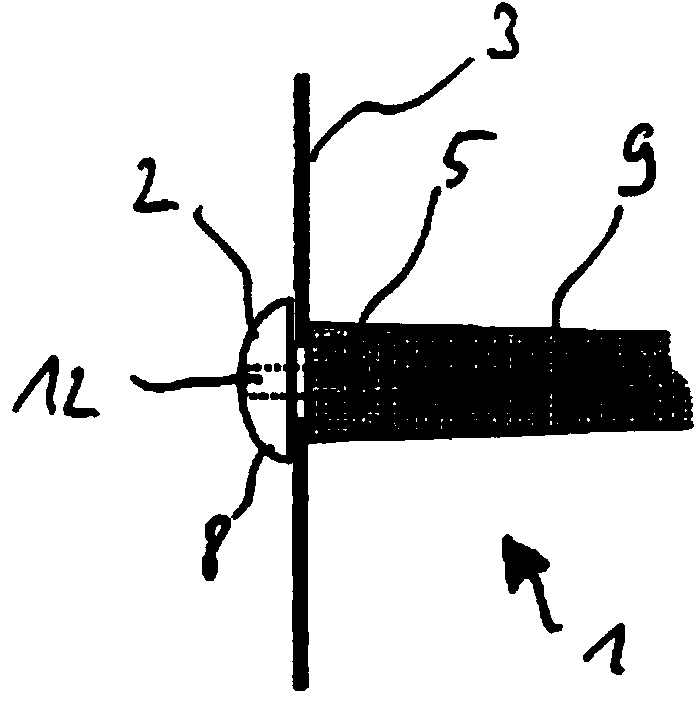

[0020] The same reference numbers in the figures indicate the same or equivalent elements.

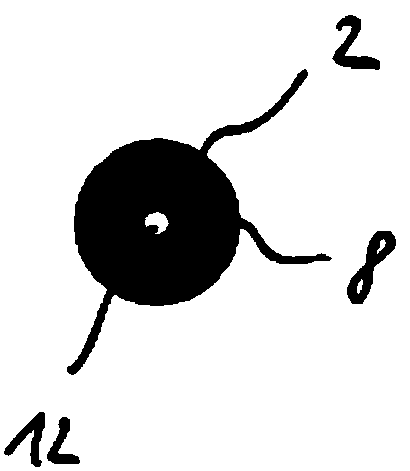

[0021] figure 1 is a schematic view of a hose coupling 1 manufactured in the wall 3 of the inlet nozzle shown according to the invention. figure 2 A top view of the rivet head 8 is schematically shown. This arrangement creates pressure measurement points.

[0022] The region of the rivet extension 5 thickened by the stretching of the mandrel of the blind rivet grips the previously inserted region of the tube 9 stably and securely.

[0023] The rivet head 8 of the blind rivet is located in the air flow region of the inlet nozzle. An air duct 12 passing through the head of the blind rivet forms the connection to the hose 9 . A pressure sensor may be connected to the hose (not shown).

[0024] Figure 3 to Figure 8 The individual steps of the method according to the invention are shown.

[0025] image 3 The wall 3 to be pierced for the sensor / hose connection is shown.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com