A rotating detonation combustor with unidirectional propagation of detonation waves

A combustion chamber and detonation wave technology, applied in the field of aerospace power, can solve the problem of uncontrollable detonation wave propagation direction, and achieve the effect of simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

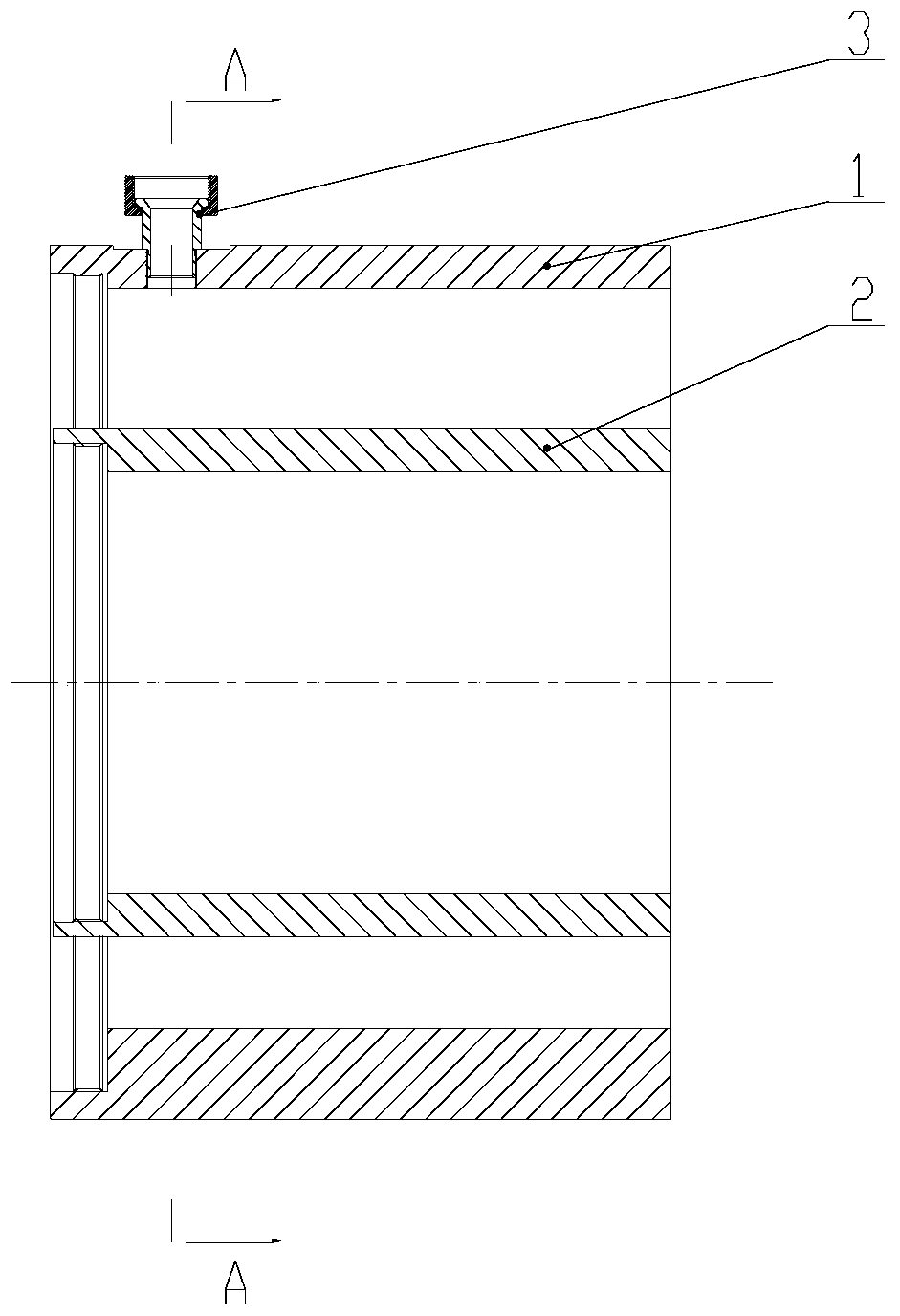

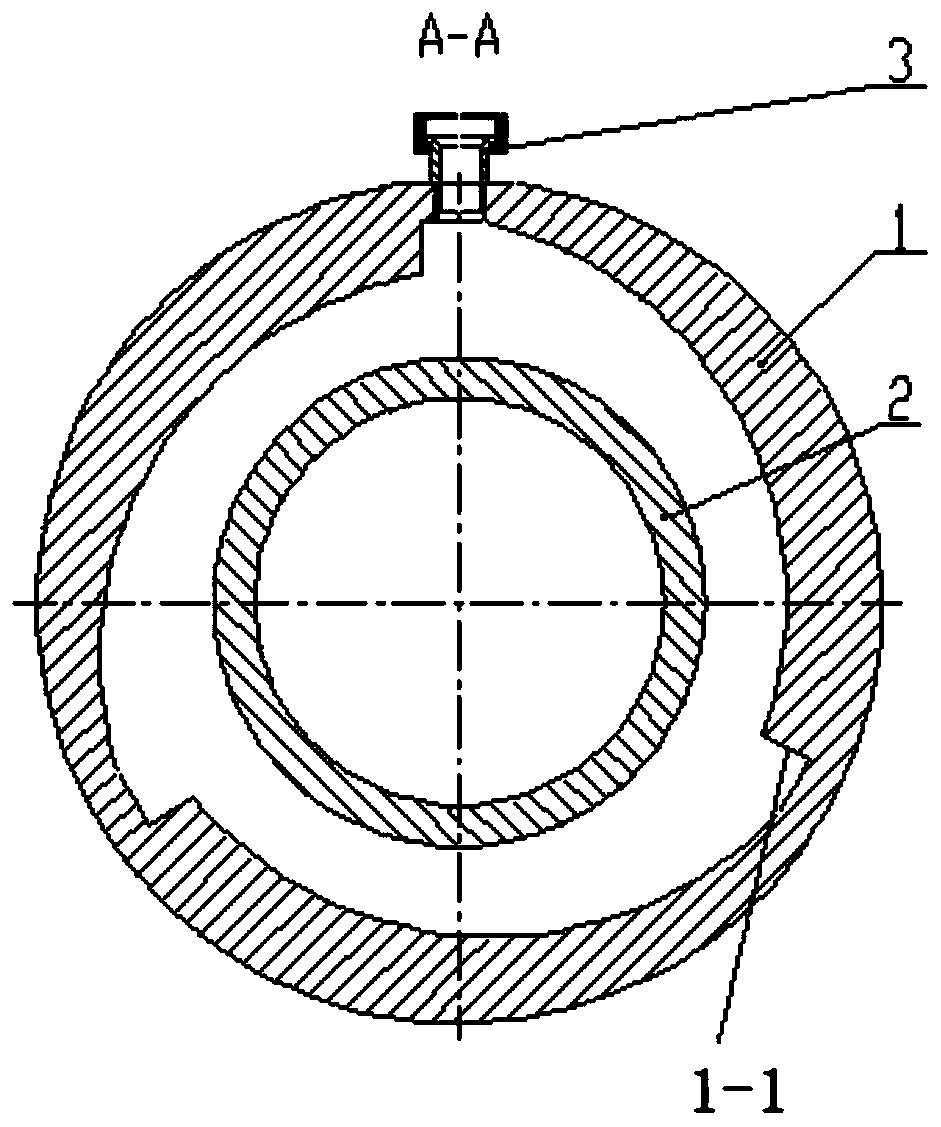

[0016] combine Figure 1-Figure 2 , a rotary detonation combustor of the present invention that allows detonation waves to propagate in one direction, comprising an outer ring 1 of the combustion chamber, an inner ring 2 of the combustion chamber, a mounting seat 3, and an igniter;

[0017] The combustion inner ring 2 is coaxial with the combustion outer ring 1; the outer wall surface of the combustion inner ring 2 is a cylindrical surface; the inner wall surface of the combustion outer ring 1 is a periodic tapering and sudden expansion surface, The number of cycles is n, n≥2, the radius of curvature of the inner wall of the tapered section gradually becomes smaller, and a step surface 1-1 is formed between the sudden expansion section and the next cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com