Compressor wheel

A technology of compressors and superchargers, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of air heating, low internal combustion engine power, etc., and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

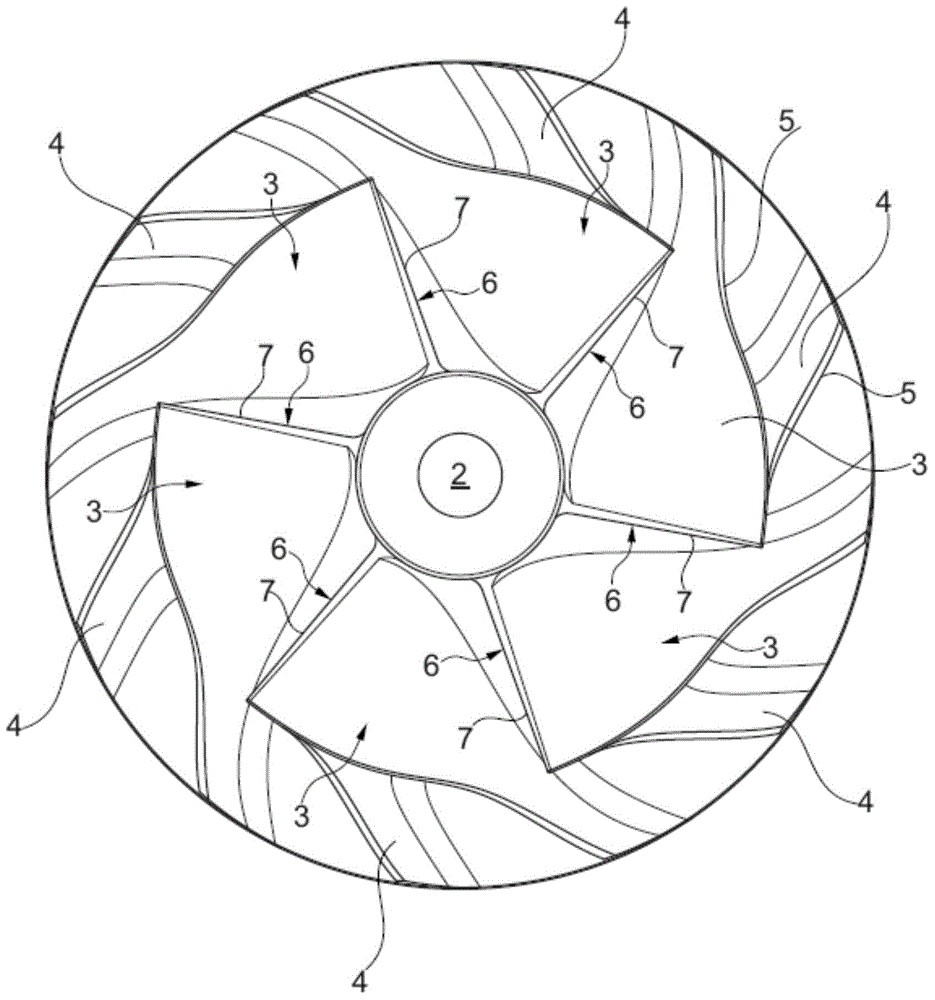

[0026] figure 1 The radial compressor wheel 1 shown in has a central shaft hole 2 by means of which the radial compressor wheel 1 can be arranged on the corresponding segment of the motor shaft, in the case of a turbocharger, Corresponding sections of the motor shaft connect the compressor wheel 1 to the turbine wheel in a rotatably fixed manner. During turbocharger operation, the turbine wheel is driven within the turbine housing by the exhaust gas flow of the internal combustion engine and then drives the radial compressor wheel 1 . In the illustrated embodiment, the compressor wheel 1 has six main blades 3 arranged in each case between auxiliary blades 4 . All blades 3 and 4 have a contoured edge 5 whose shape matches the internal contour of a compressor shroud, not shown, which receives the radial compressor wheel 1 . Thus, the contour of the edge 5 and the inner surface of the inner shroud match each other so that a "sealing gap" as close as possible is formed.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com