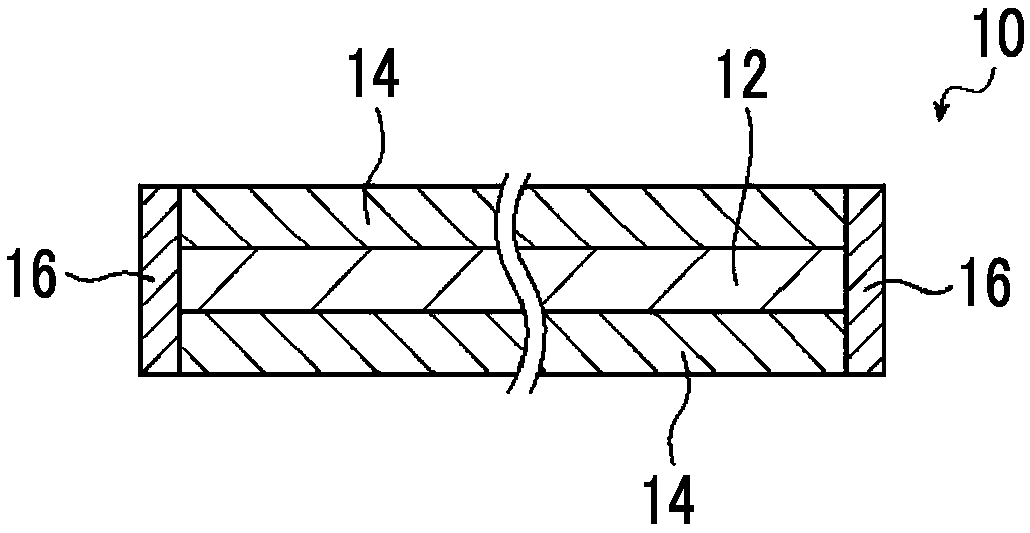

Laminate film

A technology of laminated film and laminated body, applied in the direction of layered products, layered product processing, synthetic resin layered products, etc., can solve problems such as quantum dot degradation, and achieve the effect of preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

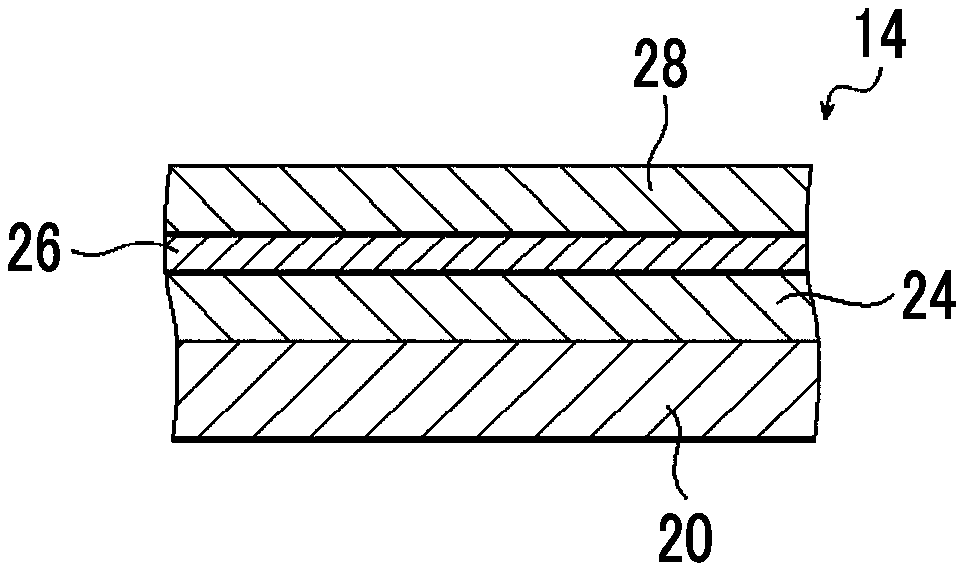

Method used

Image

Examples

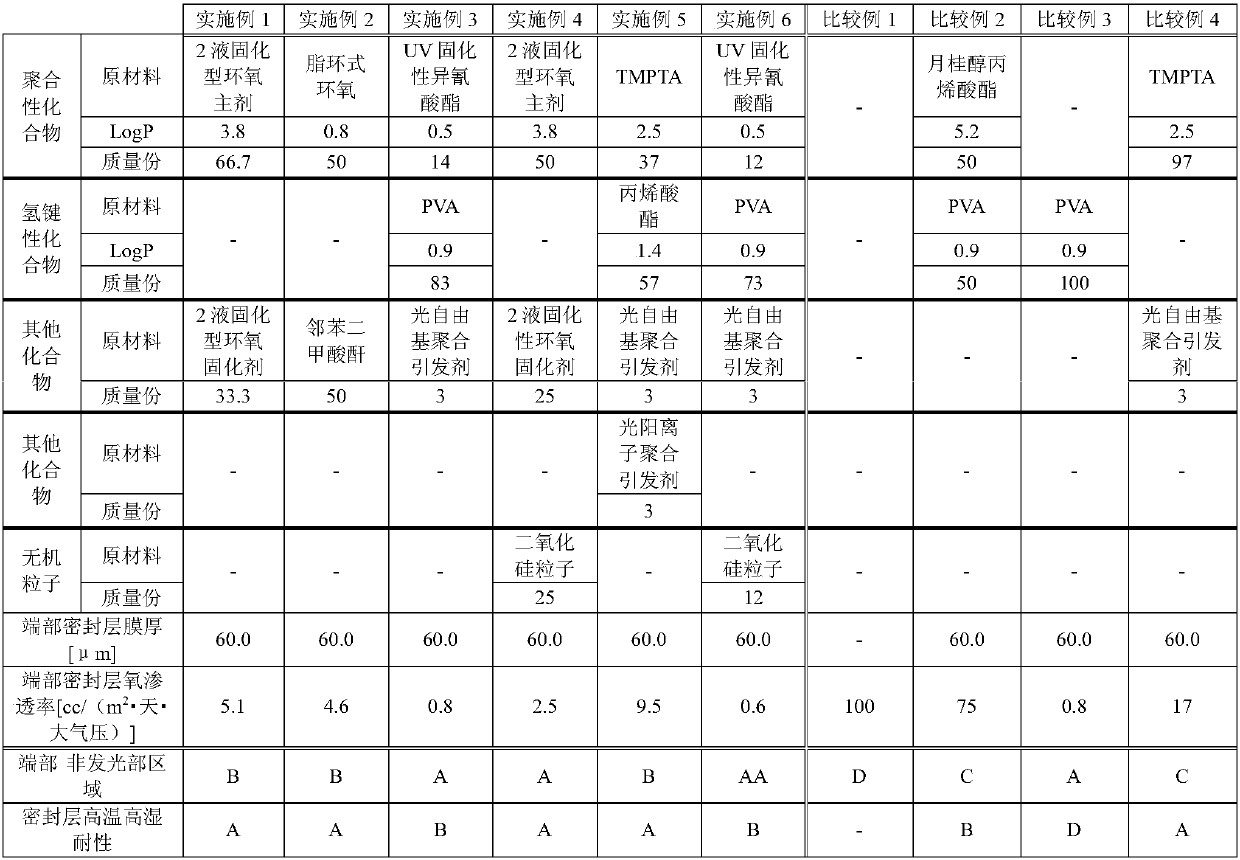

Embodiment 1

[0254] As the composition for forming the end face sealing layer 16, a composition having the following composition in solid content was prepared. In addition, a composition is mass parts when the whole solid content is made into 100 mass parts.

[0255] · 66.7 parts by mass of 2-component main ingredient of curable epoxy compound (polymerizable compound, degree of hydrophilicity logP=3.8, manufactured by Henkel Japan Ltd., LOCTITE E-30CL)

[0256] · 33.3 parts by mass of 2 liquid curing agent for curing epoxy compound (manufactured by Henkel Japan Ltd., LOCTITE E-30CL curing agent)

[0257] This composition was applied by dripping to the entire end surface of the stacked laminated body of 1000 sheets, dried and cured at 80° C. for 10 minutes, thereby forming the end surface sealing layer 16 .

[0258] Thereafter, each laminated body was peeled off, and the end face sealing layer 16 was formed on the end face of the laminated body in which the gas barrier layer 14 was laminat...

Embodiment 2

[0263] The laminated film 10 was produced in the same manner as in Example 1 except that the solid content of the composition forming the end face sealing layer 16 was the composition shown below.

[0264] 50 parts by mass of an alicyclic epoxy compound (polymerizable compound, degree of hydrophilicity logP=0.8, manufactured by Daicel Chemical Industries Ltd., CELLOXODE 2021P)

[0265] 50 parts by mass of phthalic anhydride

[0266] The oxygen permeability of the end face sealing layer 16 was measured in the same manner as in Example 1. As a result, the oxygen permeability was 4.6cc / (m 2 ·day·atmospheric pressure).

Embodiment 3

[0268] The laminated film 10 was produced in the same manner as in Example 1 except that the solid content of the composition to be the end face sealing layer 16 was the composition shown below.

[0269] ・14 parts by mass of UV curable isocyanate compound (polymerizable compound, degree of hydrophilicity logP=0.5, manufactured by Showa Denko Co., Ltd., Karenz moi)

[0270] ・Polyvinyl alcohol (hydrogen bonding compound, degree of hydrophilicity logP=0.9, manufactured by KURARAY CO., LTD., PVA117H) 83 parts by mass

[0271] 3 parts by mass of photoradical polymerization initiator (manufactured by BASF Corporation, Irgacure 184)

[0272] In addition, in this example, after coating and drying the composition to be the end face sealant layer 16, ultraviolet rays were irradiated (accumulated irradiation dose was about 800 mJ / cm 2 ), thereby curing the composition, thereby forming the end face sealing layer 16.

[0273] With the same method as Example 1, the oxygen permeability of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com