Novel soot-formation-preventing SCR denitration device

An anti-dusting, SCR reactor technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of rectifying grid fouling, easy wear and damage of catalyst, etc., achieve uniform distribution of flue gas, avoid The effect of flue gas deviation, reduction of reducing agent consumption and catalyst damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

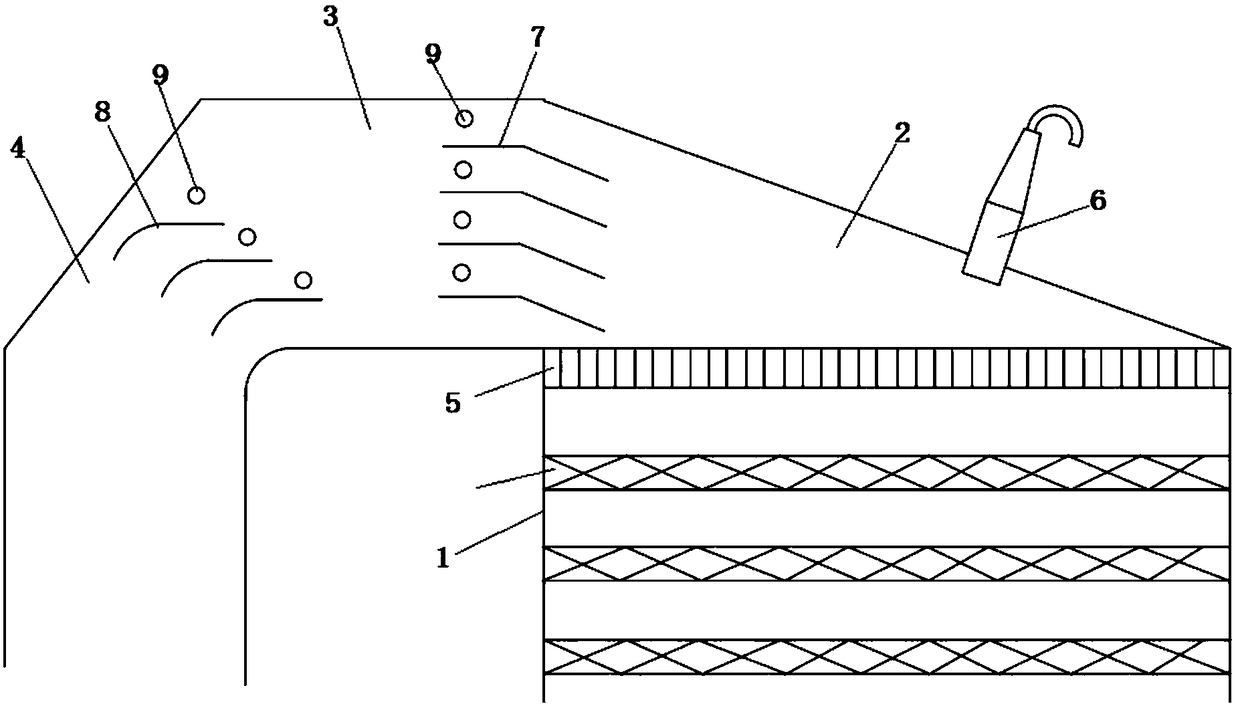

[0018] A new type of anti-accumulation SCR denitrification reaction device, including an SCR reactor body 1, an inlet mouth 2, a horizontal flue 3 and a diversion flue 4, the inlet mouth 2 is slope-shaped, and the lower end of the inlet mouth 2 is set on the SCR The reactor body 1 is above the inlet and communicates with the SCR reactor body 1 , the upper end of the inlet mouth 2 communicates with the horizontal flue 3 , and the horizontal flue 3 communicates with the turning flue 4 .

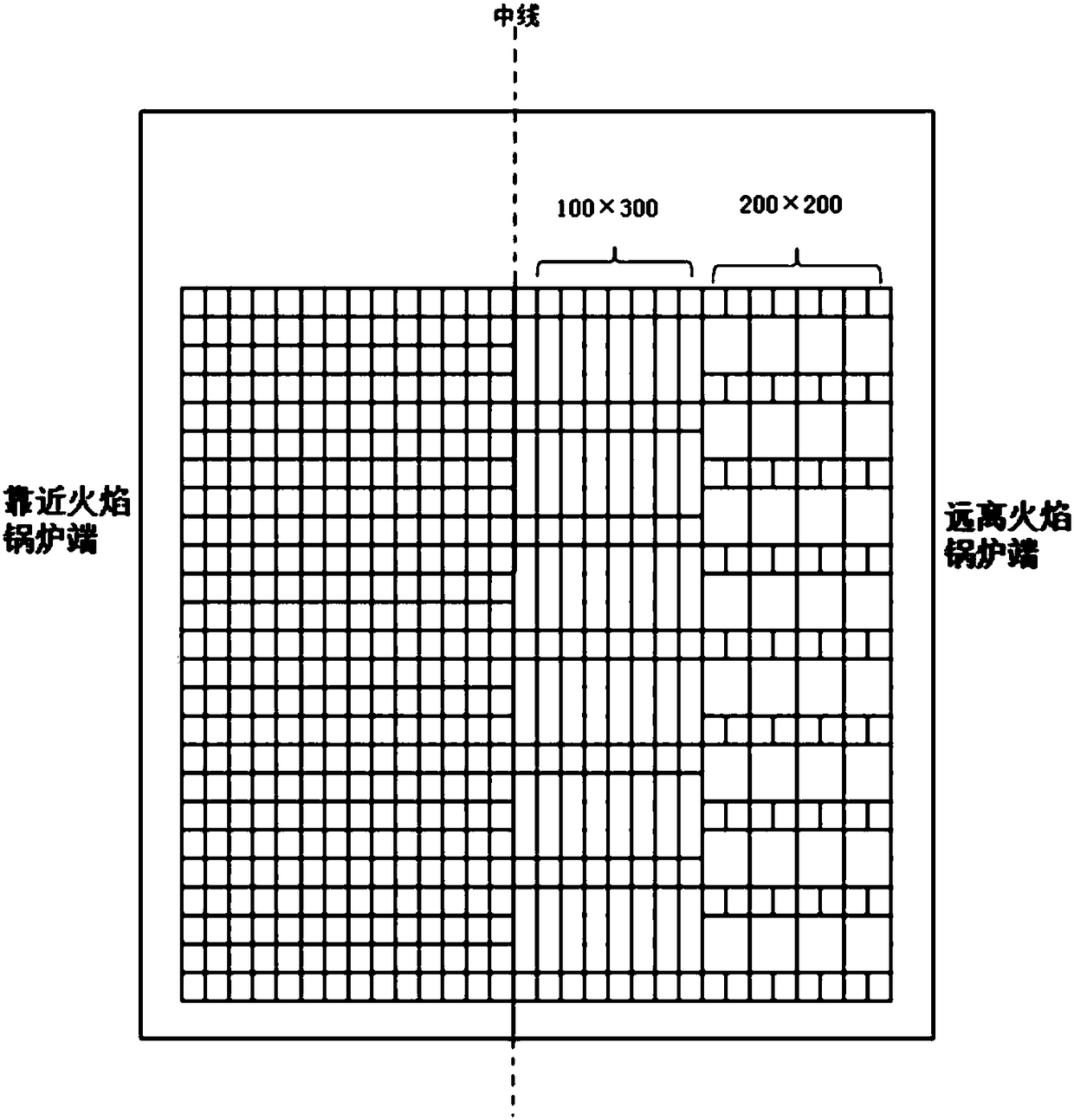

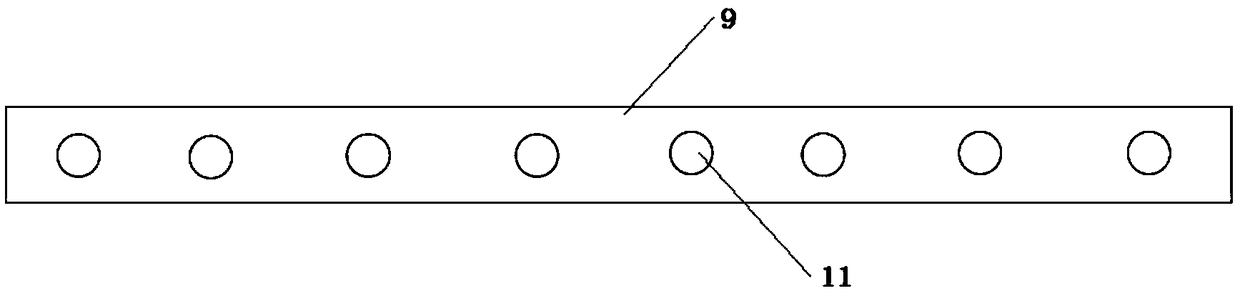

[0019] It also includes five rectifying grids 5, the five rectifying grids 5 are arranged at the entrance of the SCR reactor body 1 along the width direction of the SCR reactor body 1, and the rectifying grids 5 are away from the grid at one quarter of the flame boiler end. The grids are arranged alternately along the width direction of the SCR reactor body 1 according to the hole spacing of 100×100mm and 200×200mm. The method is arranged alternately along the width direction of the SCR reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap