A preparation method of shape-memory polyurethane micro-nanocapsules and its driving method

A driving method and polyurethane technology, applied in the field of functional polymers, can solve problems such as the inability to effectively encapsulate drug molecules, control the release rate of drugs, and deliver drugs to targeted organs, and achieve biocompatibility and reliability. The effect of degradability, large deformation, and fast shape recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

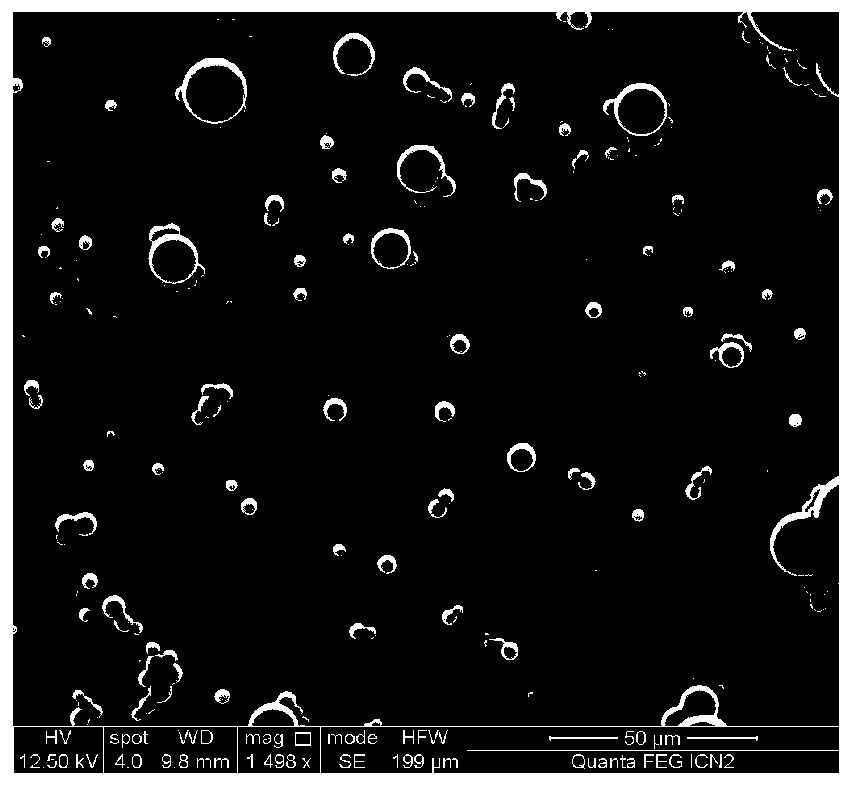

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing shape-memory polyurethane micro-nanocapsules and its thermal driving method, which specifically includes the following steps:

[0030] 1. The isocyanate Soluble in the oil phase system of dioctyl terephthalate, stir at room temperature until completely dissolved to obtain an isocyanate solution; dissolve polyethylene glycol (molecular weight 4000) in the water phase system, the water phase system is polyvinyl alcohol (PVA) (86%-89% degree of polymerization, medium molecular weight) an aqueous solution with a mass concentration of 0.1%-5%, stirred at room temperature until uniformly dispersed to obtain a polyethylene glycol solution.

[0031] 2. Pour the isocyanate solution and polyethylene glycol solution obtained in step 1 into a beaker according to the molar ratio of isocyanate to polyethylene glycol 2:1, and stir for 5 minutes at a speed of 10,000 rpm to obtain a uniform emulsion; Pour it into a three-necked flask, pu...

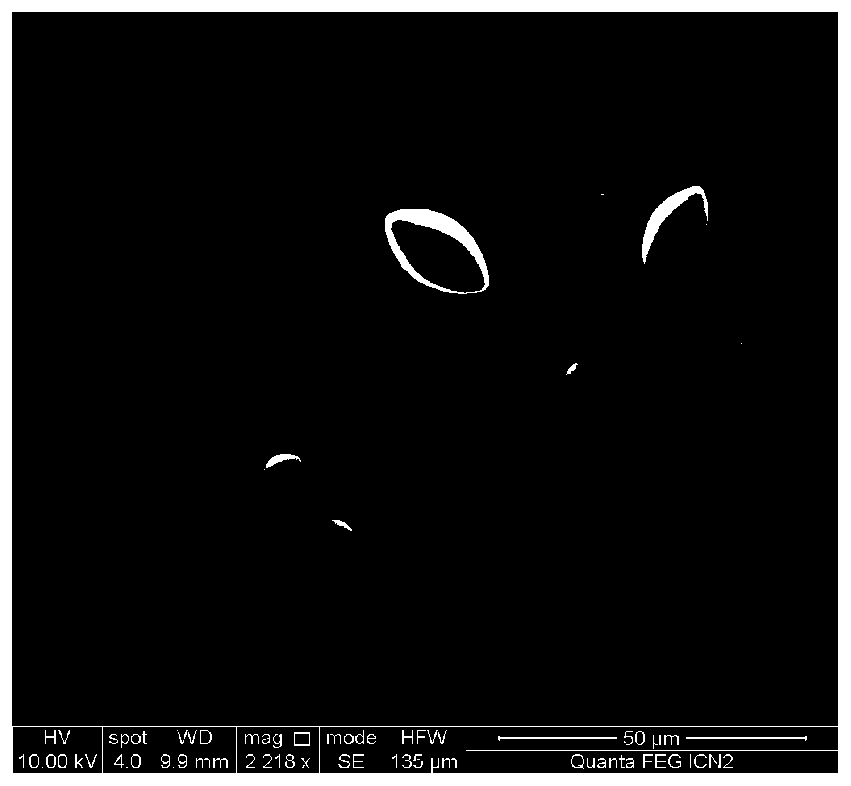

Embodiment 2

[0036] This embodiment provides another method for preparing shape-memory polyurethane micro-nanocapsules and its thermal driving method, which specifically includes the following steps:

[0037] 1. The isocyanate Soluble in the oil phase system of dioctyl terephthalate, stir at room temperature until completely dissolved to obtain an isocyanate solution; dissolve polyethylene glycol (molecular weight 4000) in the water phase system, the water phase system is polyvinyl alcohol (PVA) (86%-89% degree of alcoholysis, medium degree of polymerization) an aqueous solution with a mass concentration of 0.1%-5%, stirred at room temperature until uniformly dispersed to obtain a polyethylene glycol solution.

[0038]2. Pour the isocyanate solution and polyethylene glycol solution obtained in step 1 into a beaker according to the molar ratio of isocyanate to polyethylene glycol 2:1, and stir for 5 minutes at a speed of 10,000 rpm to obtain a uniform emulsion; Pour it into a three-necked...

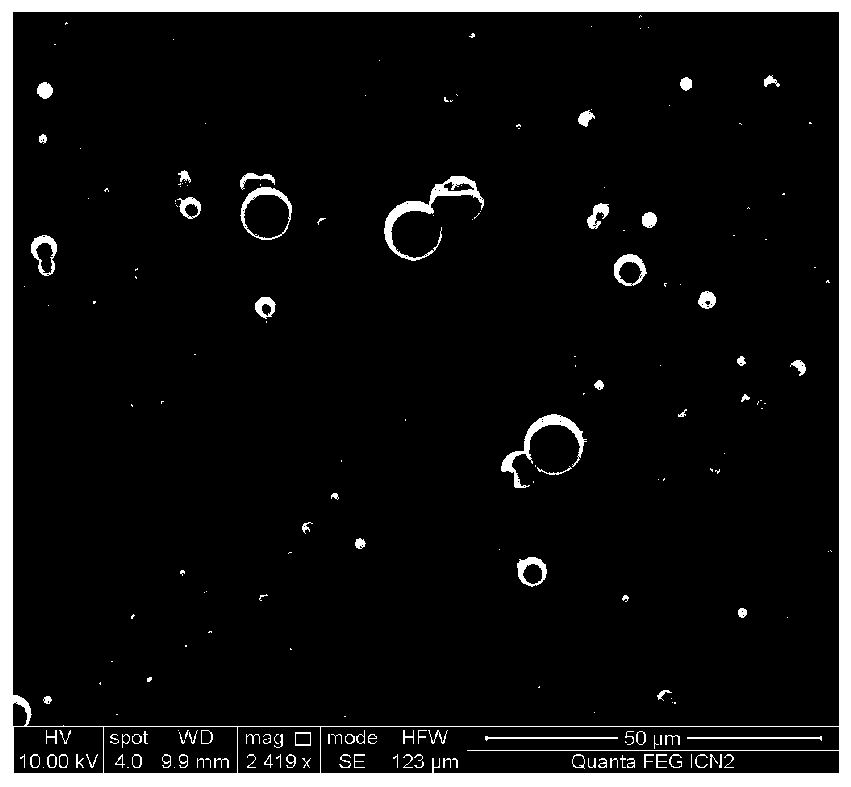

Embodiment 3

[0043] This embodiment provides another method for preparing shape-memory polyurethane micro-nanocapsules and its thermal driving method, which specifically includes the following steps:

[0044] 1. The isocyanate Soluble in the oil phase system of dioctyl terephthalate, stir at room temperature until completely dissolved to obtain an isocyanate solution; dissolve polyethylene glycol (molecular weight 4000) in the water phase system, the water phase system is polyvinyl alcohol (PVA) (86%-89% degree of alcoholysis, medium degree of polymerization) an aqueous solution with a mass concentration of 0.1% to 5%, stirred at room temperature until uniformly dispersed to obtain a polyethylene glycol solution;

[0045] 2. Pour the isocyanate solution and polyethylene glycol solution obtained in step 1 into a beaker according to the molar ratio of isocyanate to polyethylene glycol 6:1, and stir for 5 minutes at a speed of 5000 rpm to obtain a uniform emulsion; Pour it into a three-neck...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com