A kind of hydrogel for soil improvement and its preparation method and application

A soil improvement and hydrogel technology, applied in the fields of application, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of no obvious advantages and complicated preparation process, saving energy consumption and chemical reagent costs, and large-scale application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take 0.5 parts by weight of the concentrated prehydrolyzate of the pulp mill as a solvent, the content of soluble hemicellulose in the solvent is 4%, add 0.5 parts by weight of water to the solvent to dilute it twice, add 0.05 parts by weight of acrylic acid, and use KOH The neutralization ratio of acrylic acid was adjusted to 70%, and 0.001 part of N,N dimethylbisacrylamide was added, mixed in the reactor, and heated to 70°C. At the same time, after adding 0.001 parts by weight of ammonium persulfate and 0.001 parts by weight of dimethylethylenediamine, sealed and reacted for 2 hours to obtain a dark red hydrogel product, each gram of the product can absorb 30 grams of deionized water or 21 grams of tap water.

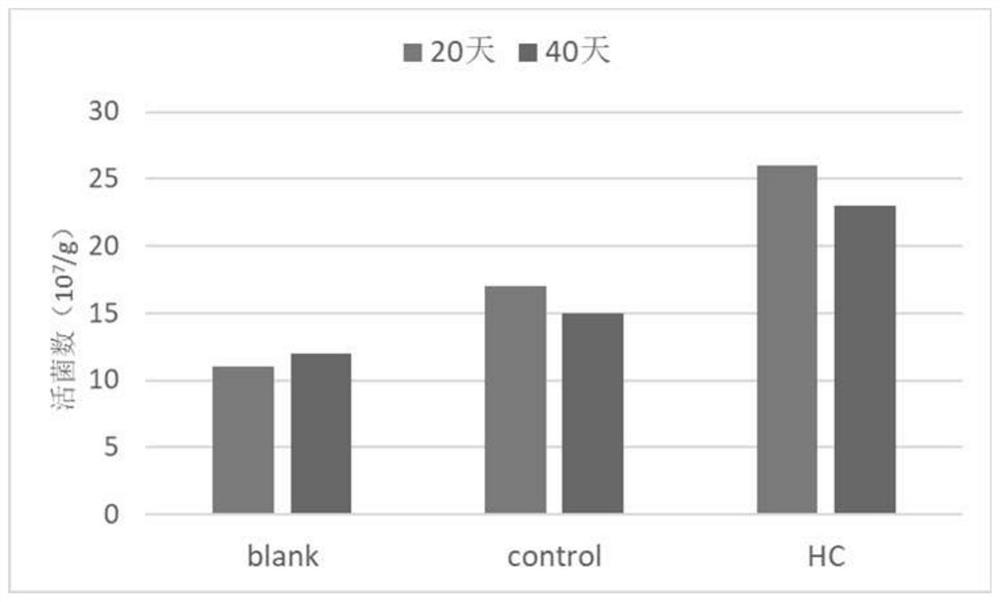

[0043] The hydrogel product is mixed with the fermented liquid of nitrogen-fixing bacteria rotunda at a weight ratio of 1:100, and then mixed with high-speed stirring equipment and then mixed with sterilized peat to obtain a water-containing solid microbial prod...

Embodiment 2

[0046] Heat 0.5 parts by weight of the alkaline hemicellulose mucus recovered from alkali squeezed in a viscose fiber factory to above 80° C. to dissolve it, add water to dilute it twice, and adjust the hemicellulose concentration to 4%. Add 0.05 parts by weight of acrylamide and 0.001 parts of N,N dimethylbisacrylamide and mix them in the reactor, add 0.001 parts by weight of ammonium persulfate and 0.001 parts by weight of dimethylethylenediamine, and seal at 70°C After reacting for 2 hours, a deep red alkaline hydrogel product was obtained. Each gram of product can absorb 45 grams of deionized water or 32 grams of tap water.

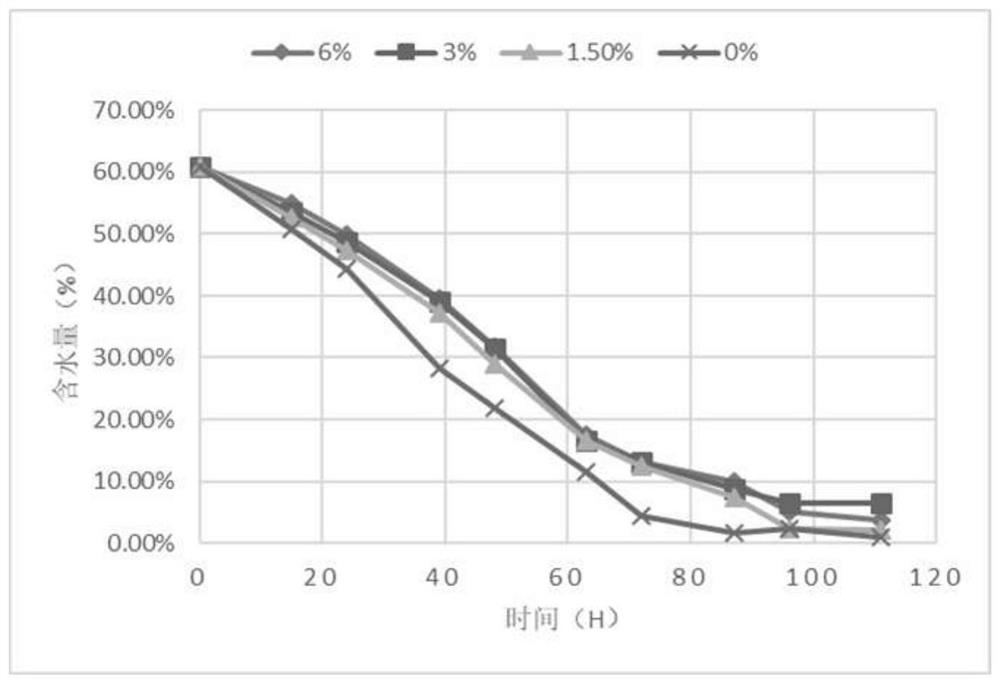

[0047] The resulting hydrogel product is mixed with decomposed sheep manure (pH alkaline) according to the method of the above-mentioned embodiment 1 to adjust the acid compacted soil, and the mixed material is added to the acid compacted soil (see figure 2 ).

[0048] In laboratory tests, when the addition amount was 1.5%, it could effectively red...

Embodiment 3

[0050] Dilute 0.5 parts by weight of the alkaline hemicellulose mucus recovered from alkali squeezed alkali in the viscose fiber factory with water, adjust the hemicellulose concentration to 4%, adjust the pH value to 2.5 with concentrated phosphoric acid, and the mucus becomes milk Yellow suspension, after reacting in a sealed reactor at 150°C for 30 minutes, a red hemicellulose solution was obtained. Using this solution as a solvent, the same method as in Example 1 was used to prepare a hydrogel product, and each gram of the product could absorb 40 grams of deionized water or 28 grams of tap water. The hydrogel product and Bacillus coagulans fermentation broth are mixed at high speed according to the weight ratio of 1:50 to obtain a viscous liquid bacterial agent product, which can be used to improve saline-alkali soil, and the addition of hydrogel can improve the growth and metabolism of microorganisms It provides a slightly acidic humid environment, which is more conducive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com