Combined steel casing for rotary drilling of cast-in-place pile in backfilled soil and construction method thereof

A steel casing and combined technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficult processing, inconvenient transportation, heavy steel casing, etc., and achieve low production cost, reliable connection, splicing safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

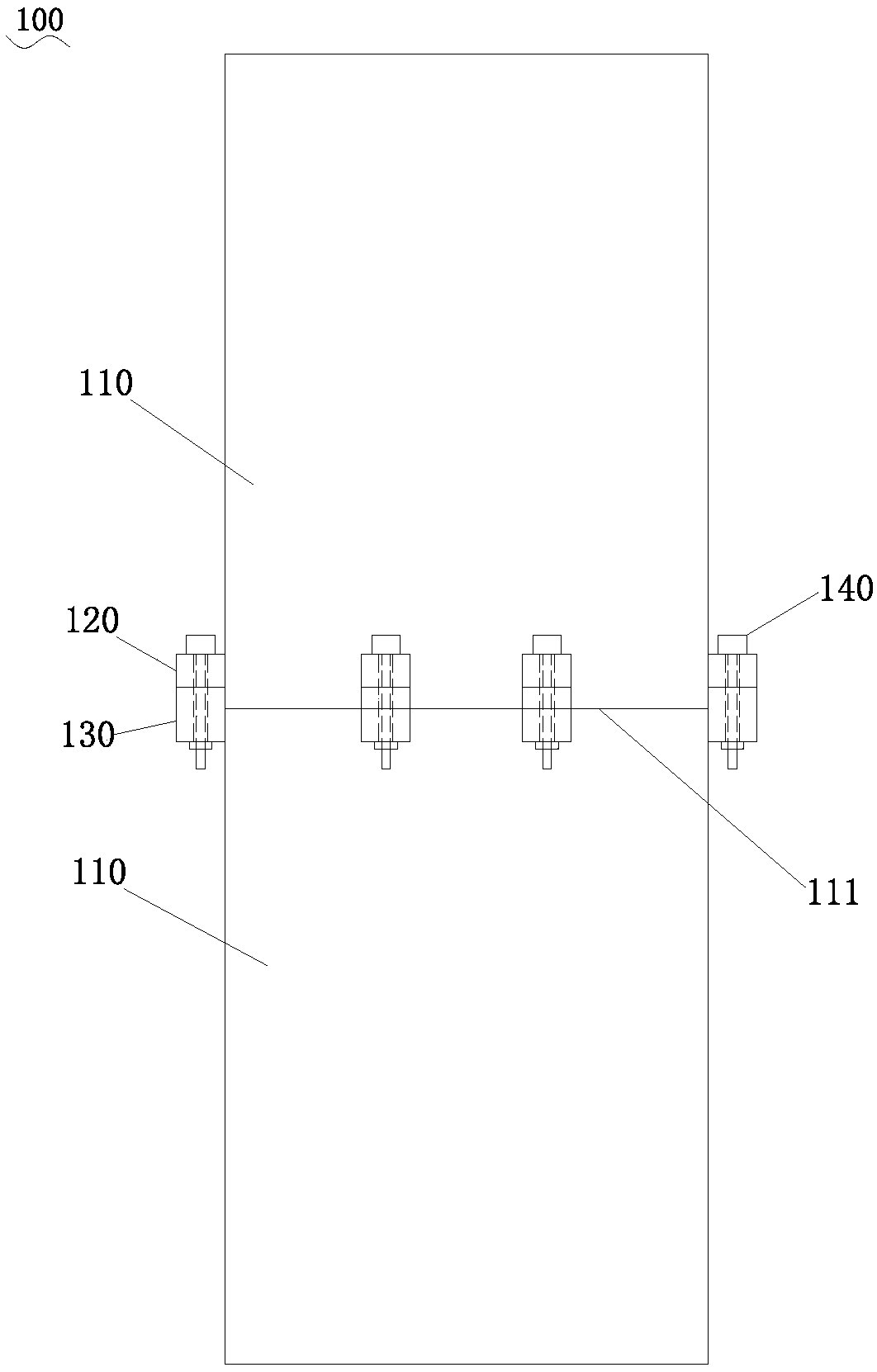

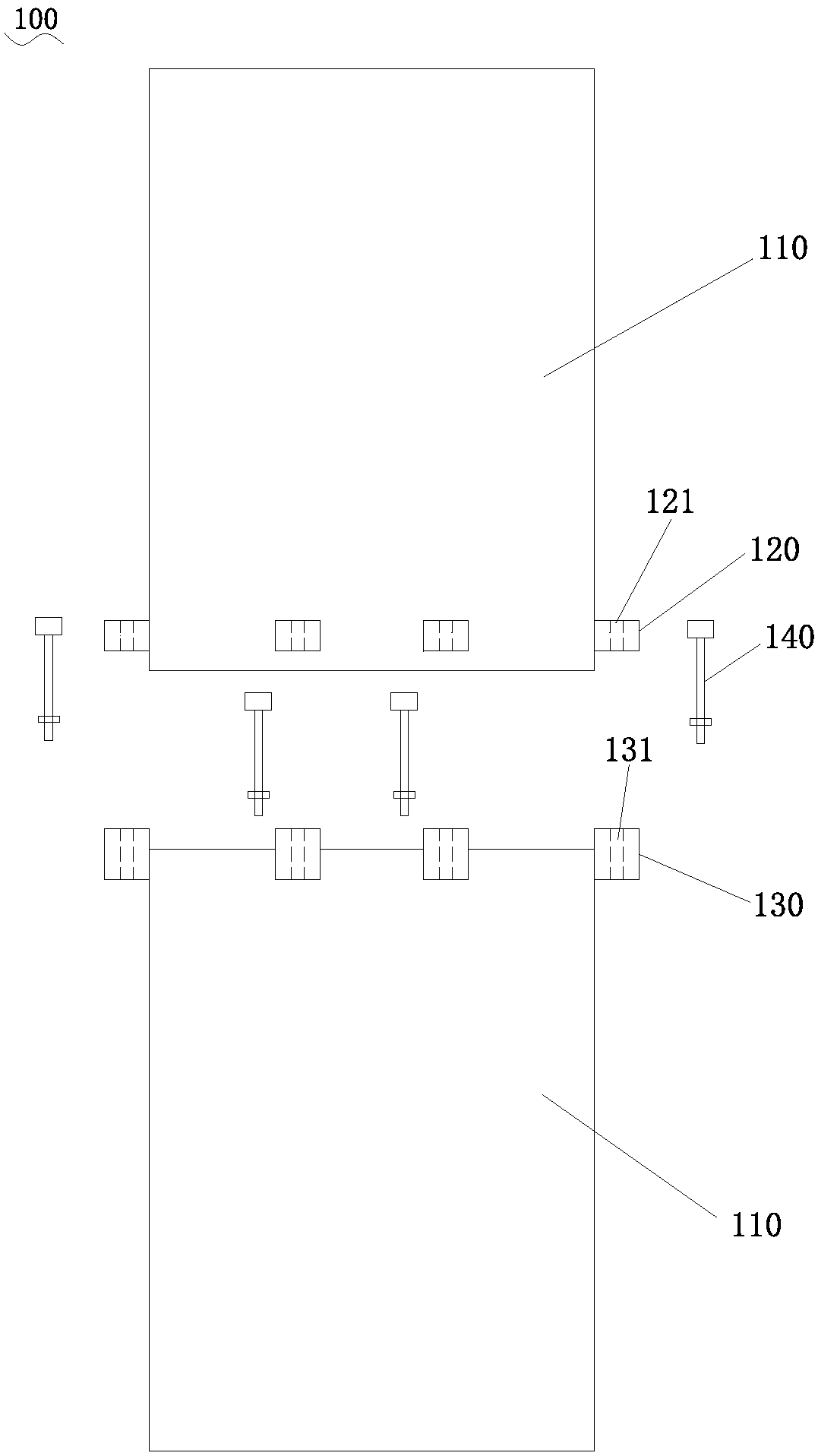

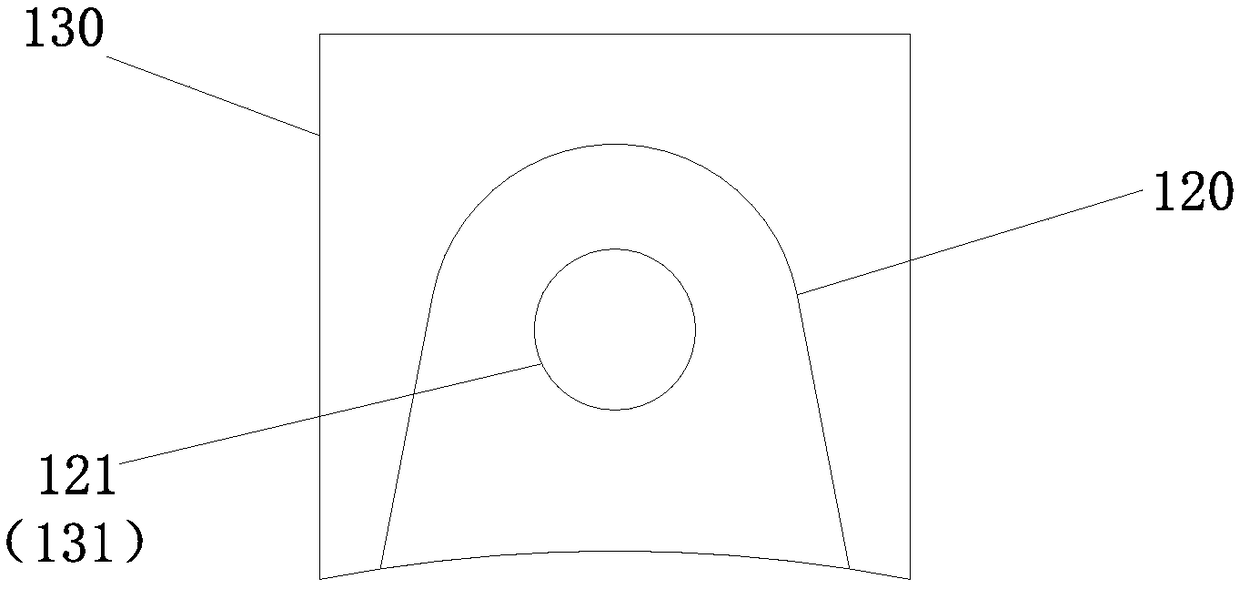

[0032] see figure 1 with figure 2 As shown, the combined steel casing 100 for backfill rotary-dug cast-in-place piles provided in this embodiment includes two steel casing units 110, the two steel casing units 110 are spliced up and down, and the steel casing above the splicing joint 111 The outer surface of the lower port of the casing unit 110 is provided with several upper connecting lugs 120, and the outer surface of the upper port of the steel casing unit 110 below the splicing seam 111 is provided with several lower connecting lugs matching the upper connecting lugs 120 130 , each pair of upper connecting lugs 120 and lower connecting lugs 130 is respectively provided with a first connecting hole 121 and a second connecting hole 131 , which are connected by bolts 140 . As an example, the combined steel casing 100 with a length of 6m is welded on site by two steel casing units 110 with a length of 3m. The steel casing unit 110 is made of 10mm manganese steel. The con...

Embodiment 2

[0039] The present invention also provides a construction method of the combined steel casing for the backfill rotary excavation cast-in-situ pile in Embodiment 1, the following is combined with the attached Figure 1 to Figure 4 The construction method is further described, specifically including the following steps:

[0040]S1. The steel casing unit 110 of the combined steel casing 100 is prefabricated in the factory, and the upper connection ear plate 120 with the first connection hole 121 and the lower connection ear plate 130 with the second connection hole 131 are welded, and transported to the construction site . Preferably, each section of steel casing unit 110 is numbered according to the construction sequence, and the lower port of the first section of steel casing unit 110 and the upper port of the last section of steel casing unit 110 are not welded with ear plates.

[0041] S2. Level the surface soil in the area to be constructed, set the line to locate the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com