Sealing oil cavity socket

A technology for sealing oil chambers and sockets, applied in engine components, machines/engines, gas turbine devices, etc., can solve the problems of increased maintenance times, prone to resonance, and large space occupied by the positioning seat, so as to overcome the inaccurate positioning and increase the The effect of oil storage and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

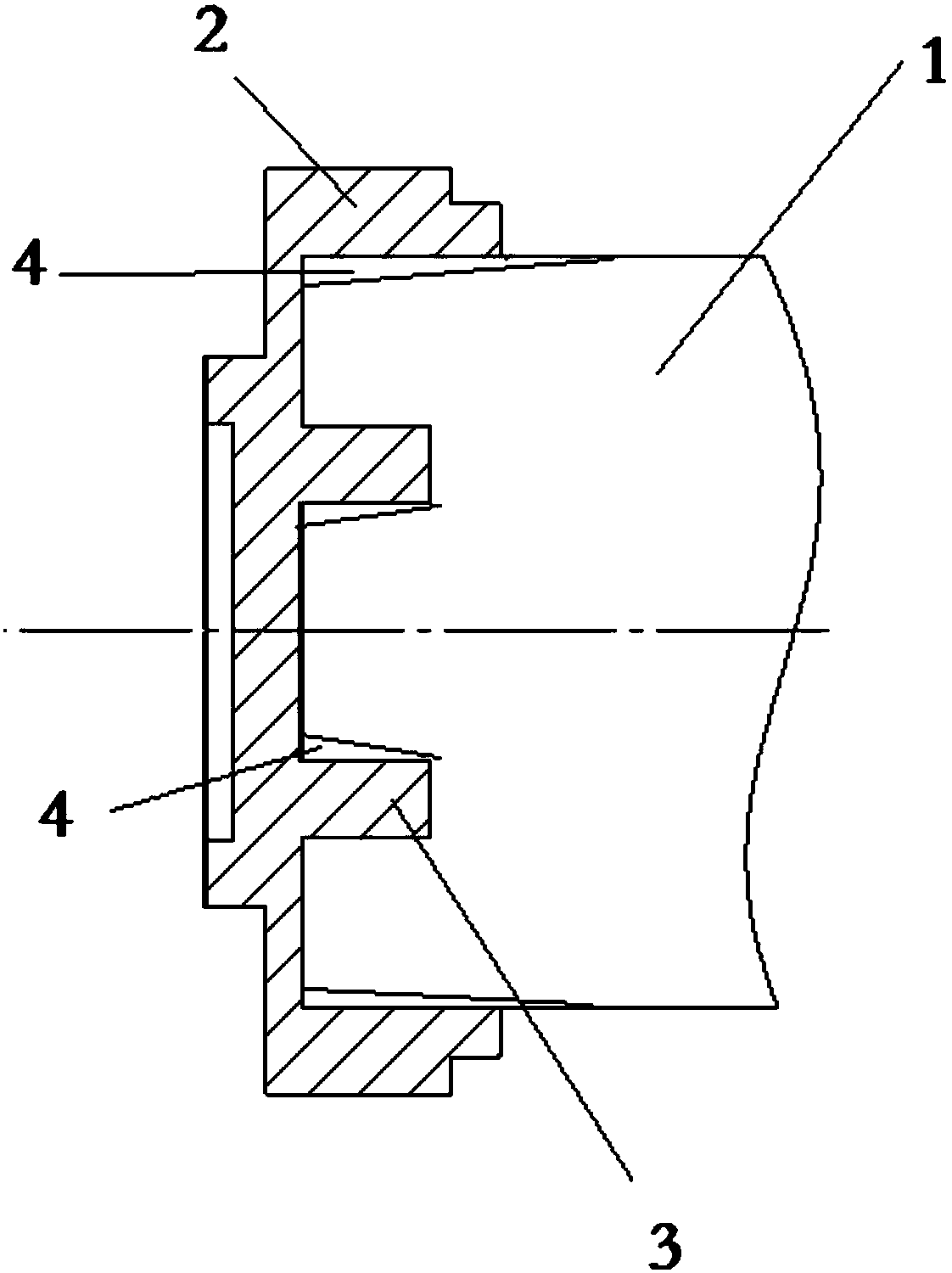

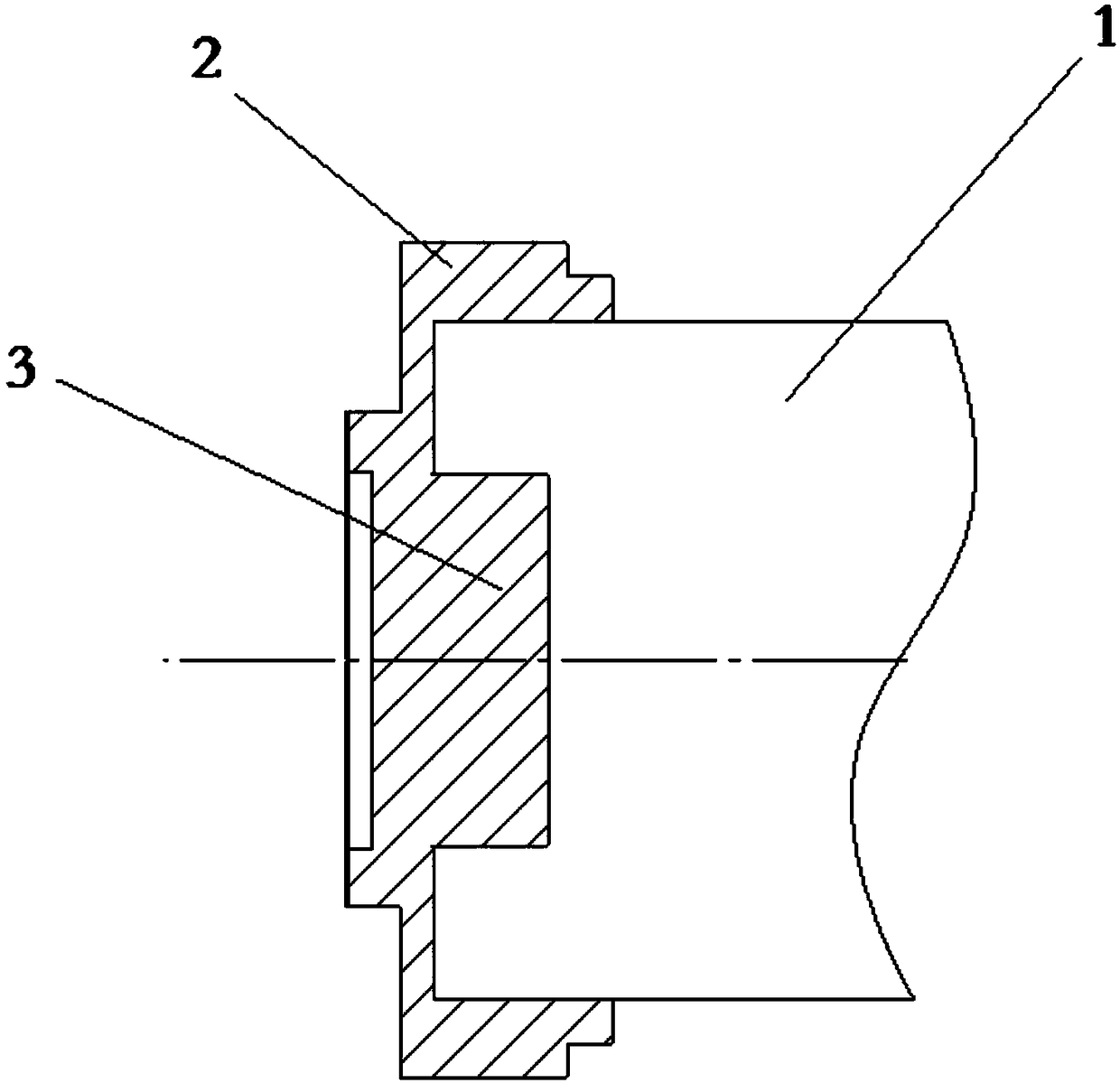

[0008] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, it includes an annular base 2, a positioning seat 3 is arranged in the middle of the base 2, and the positioning seat 3 is annular, and the inner side of the positioning seat 3 is provided with a tapered seat lining 4; the inner side of the annular base A tapered seat liner 4 is also provided; the bottom of the sealed oil chamber 1 is provided with a corresponding tapered surface.

[0009] The sealing seat lining material can be soft metal, such as copper; high temperature resistant rubber products can also be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com