Large extended atomization cone angle oil throwing plate structure

A technology of atomization cone angle and oil thrower, which is applied in combustion methods, lighting and heating equipment, continuous combustion chambers, etc., and can solve problems such as oil and gas mixing in the flame tube, small fuel atomization cone angle, and long flame tube , to achieve the effect of strengthening oil and gas mixing, improving combustion efficiency and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] For the baffle combustion chamber using the oil thrower, the present invention adds a swirl structure on the basis of the hole-type oil thrower, and tests the oil thrower to expand the atomization cone angle of the oil thrower. The swirling flow structure increases the residence time of the fuel in the flame tube, strengthens the mixing of oil and gas, improves the combustion efficiency and shortens the axial length of the flame tube.

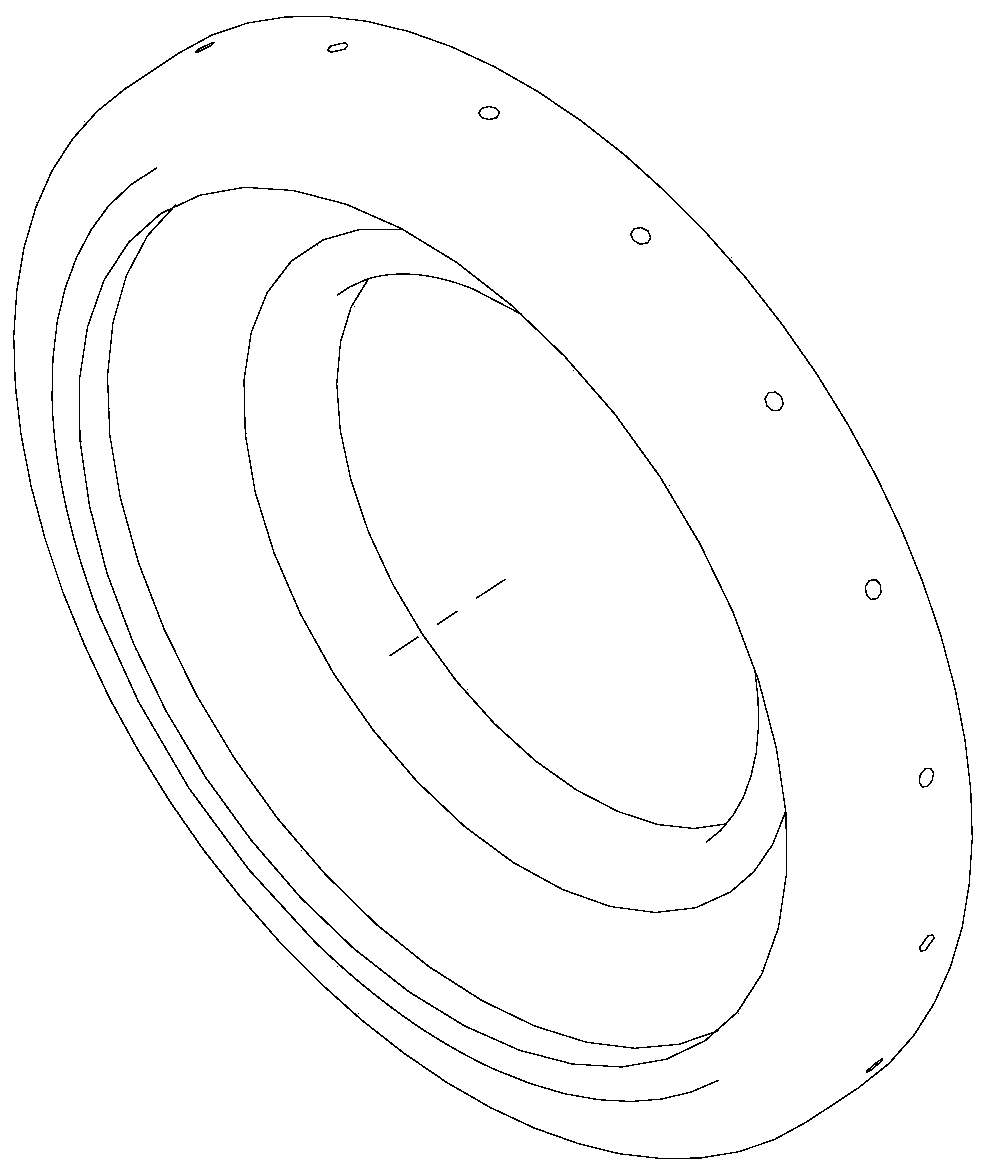

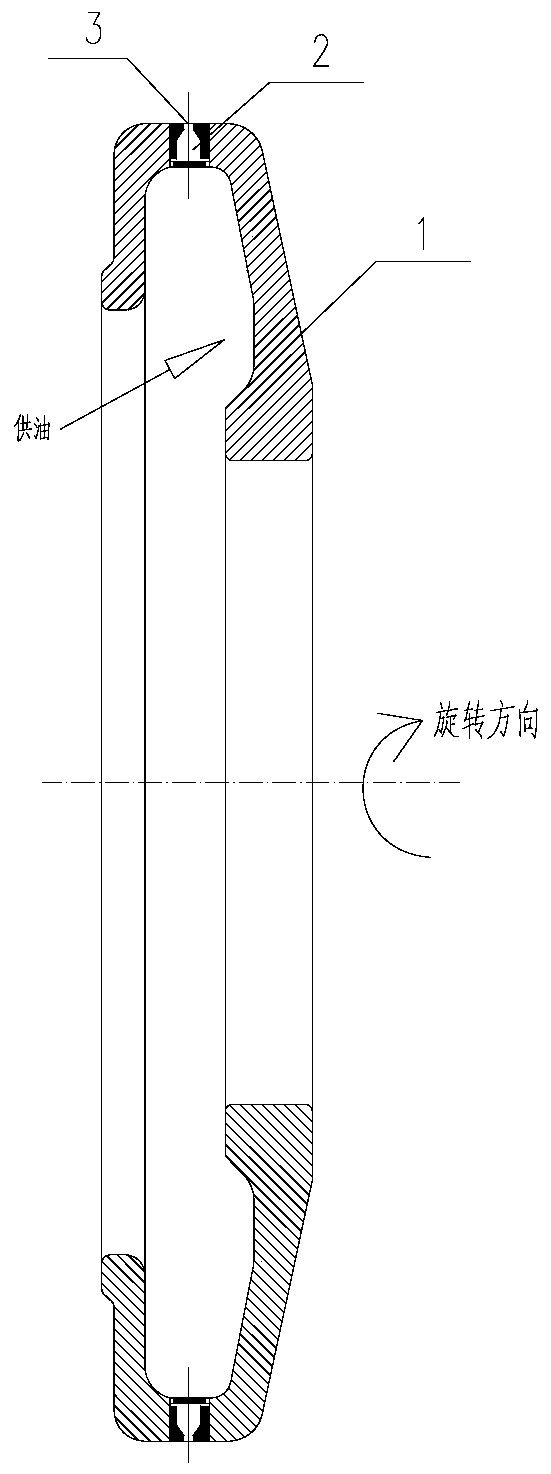

[0029] In order to solve the problems of the prior art, the present invention provides a large extended atomization cone angle oil throwing pan structure, such as figure 1 and figure 2 As shown, it includes: oil thrower 1, swirl chamber 2, fuel nozzle 3; the direction of air fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com