Workshop humidity control device

A workshop and cabinet technology, applied in the field of industrial humidity control, can solve problems such as short circuit of electronic components, affecting the performance of electronic components, etc., to achieve the effect of saving water resources and enhancing the effect of humidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

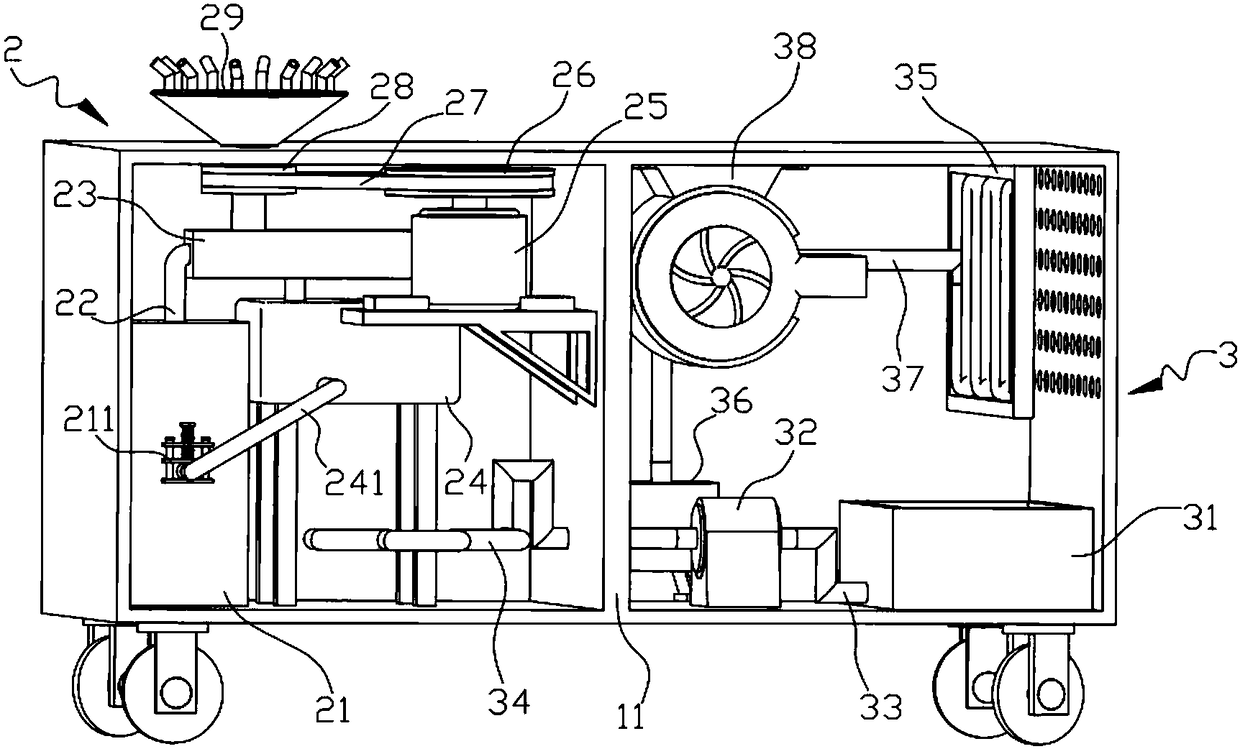

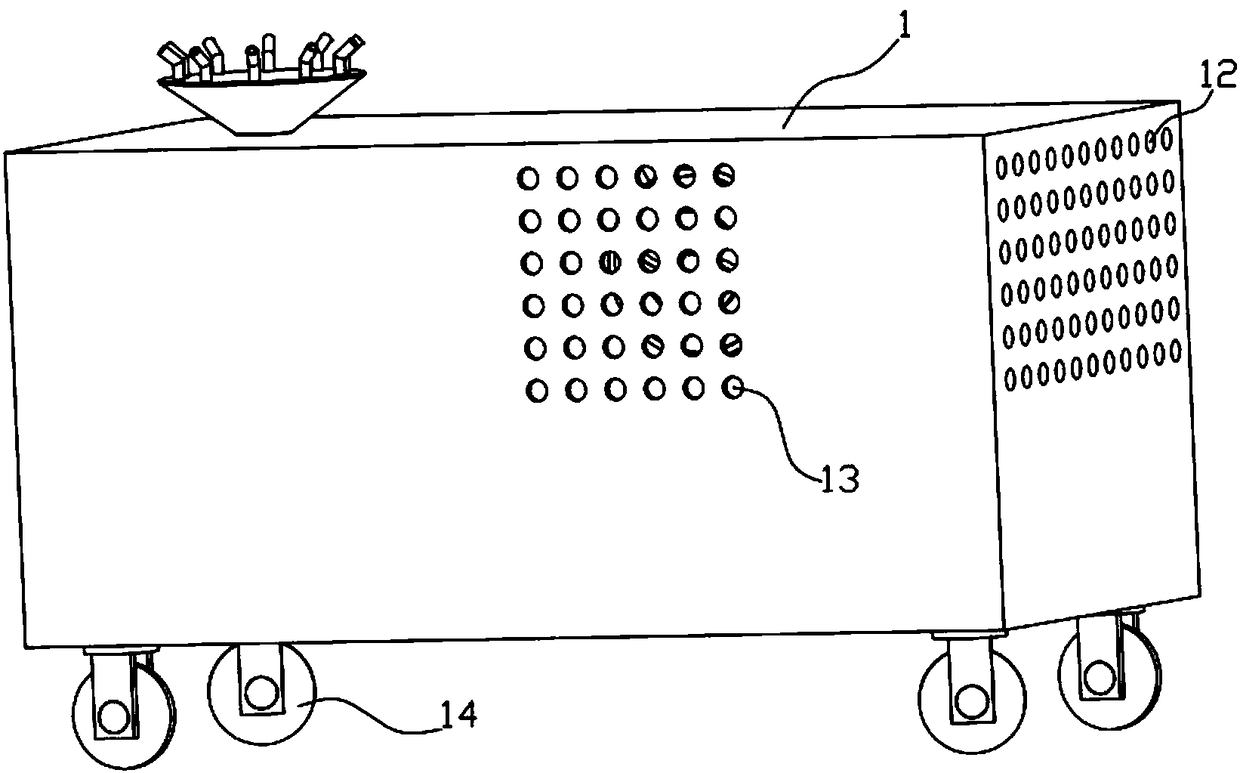

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0025] A humidity control device for a workshop, including a box body 1, a humidification mechanism 2 and a dehumidification mechanism 3, wherein a heat insulation board 11 is arranged inside the box body 1, and the heat insulation board 11 divides the box body 1 into two chambers, one of which is The humidification mechanism 2 is installed, and the dehumidification mechanism 3 is installed in the other chamber. One side of the box body 1 is provided with a number of air inlet holes 12, the other side of the box body 1 is provided with a number of air outlet holes 13, and the lower side of the box body 1 is equipped with four Universal wheel 14, wherein:

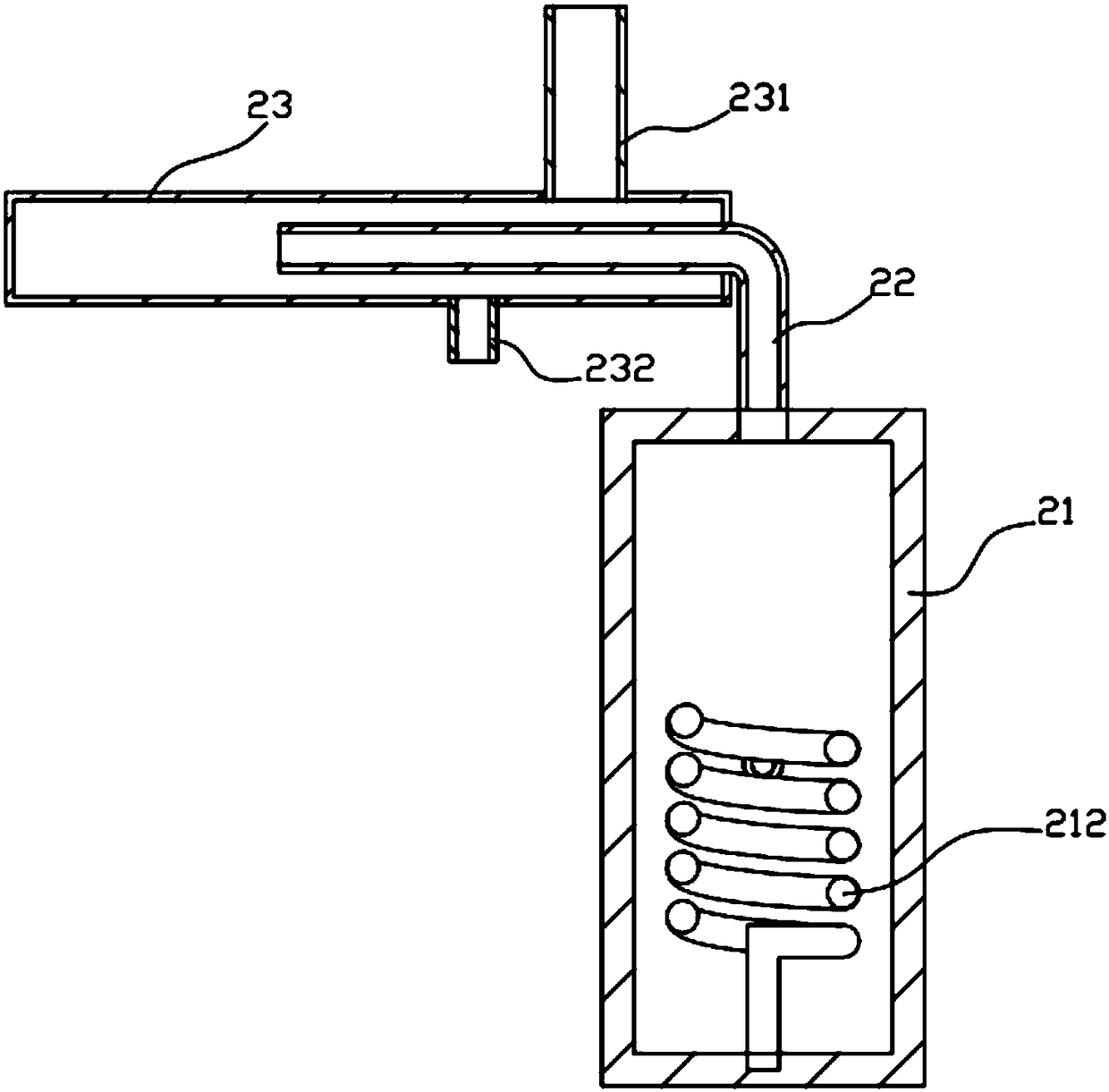

[0026] Humidifying mechanism 2, it comprises heating box 21, steam pipe 22, condensing pipe 23, condensed water tank 24, motor 25, driving pulley 26, belt 27, driven pulley 28 and steam nozzle 29, and heating box 21 is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com