Performance Characterization Method of Stainless Steel Elbows Used in Power Plant Boilers

A power station boiler, stainless steel technology, applied in the direction of strength characteristics, instruments, test material hardness, etc., can solve problems such as leaking and bursting pipe accidents, and achieve the effect of improving operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

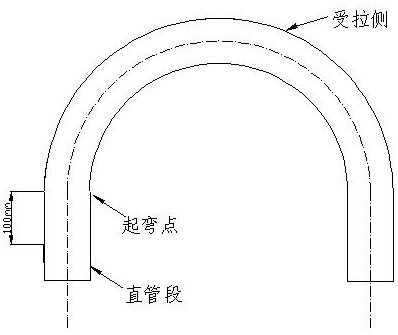

[0021] A method for characterizing the performance of stainless steel elbows used in power plant boilers. The method mainly uses the hardness difference method to characterize the performance of the elbows. The method includes the following steps:

[0022] (1) The substance to be characterized is a bent pipe for a power station boiler, and the said bent pipe for a power station boiler is made of stainless steel.

[0023] (2) After the bending pipe is processed, due to the processing hardness, the hardness value of the tensile side of the bending pipe will increase, and the hardness difference method is used to characterize the performance of the bending pipe used in the power plant boiler, wherein the hardness difference value is obtained by the power plant boiler. It is obtained by subtracting the hardness value of the tension side of the bend from the hardness value of the straight pipe section.

[0024] (3) Use a Leeb hardness tester for hardness measurement without damagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com