Arc extinguishing spray pipe for gas generating and arc extinguishing device

An arc extinguishing device and arc extinguishing technology, used in electrical components, high-voltage air circuit breakers, electrical switches, etc., can solve problems such as poor circuit contact, strong impact force, skin arc burns, etc., to improve equipment safety and reduce airflow. Impact force, the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and beneficial effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

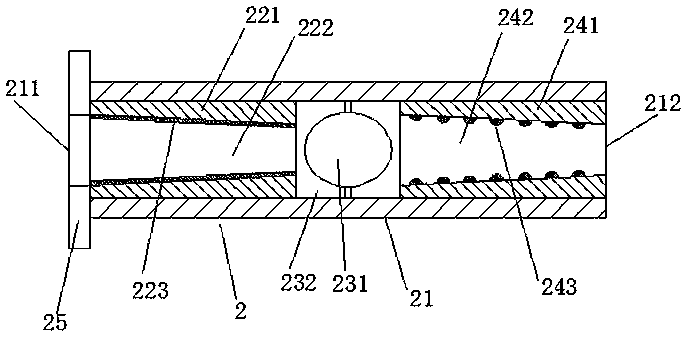

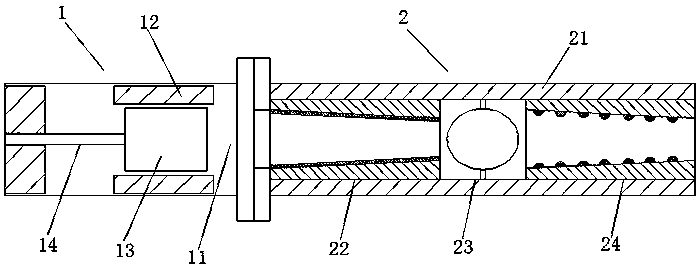

[0022] As shown in the figure, an arc extinguishing nozzle for a gas generation arc extinguishing device, the arc extinguishing nozzle 2 is arranged at the port of the gas injection hole 11 of the arc extinguishing chamber 1 in the arc extinguishing device, and the arc extinguishing nozzle 2 It includes an insulating sleeve 21 and an air inlet 211 and an air outlet 212 arranged on both sides of the insulating sleeve. The inner cavity of the pipe 21 is provided with a diversion chamber 22, a choke chamber 23 and a buffer chamber 24 sequentially along the air inlet 211 to the air outlet 212;

[0023] Specifically analyze the structure of the diversion chamber 22: the diversion chamber 22 includes a heat-insulation inner sleeve I221 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com