Full-automatic investment wax injection device

A fully automatic, wax injection technology, applied in the field of investment casting, can solve the problems of low production efficiency and increase labor intensity, and achieve the effect of strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

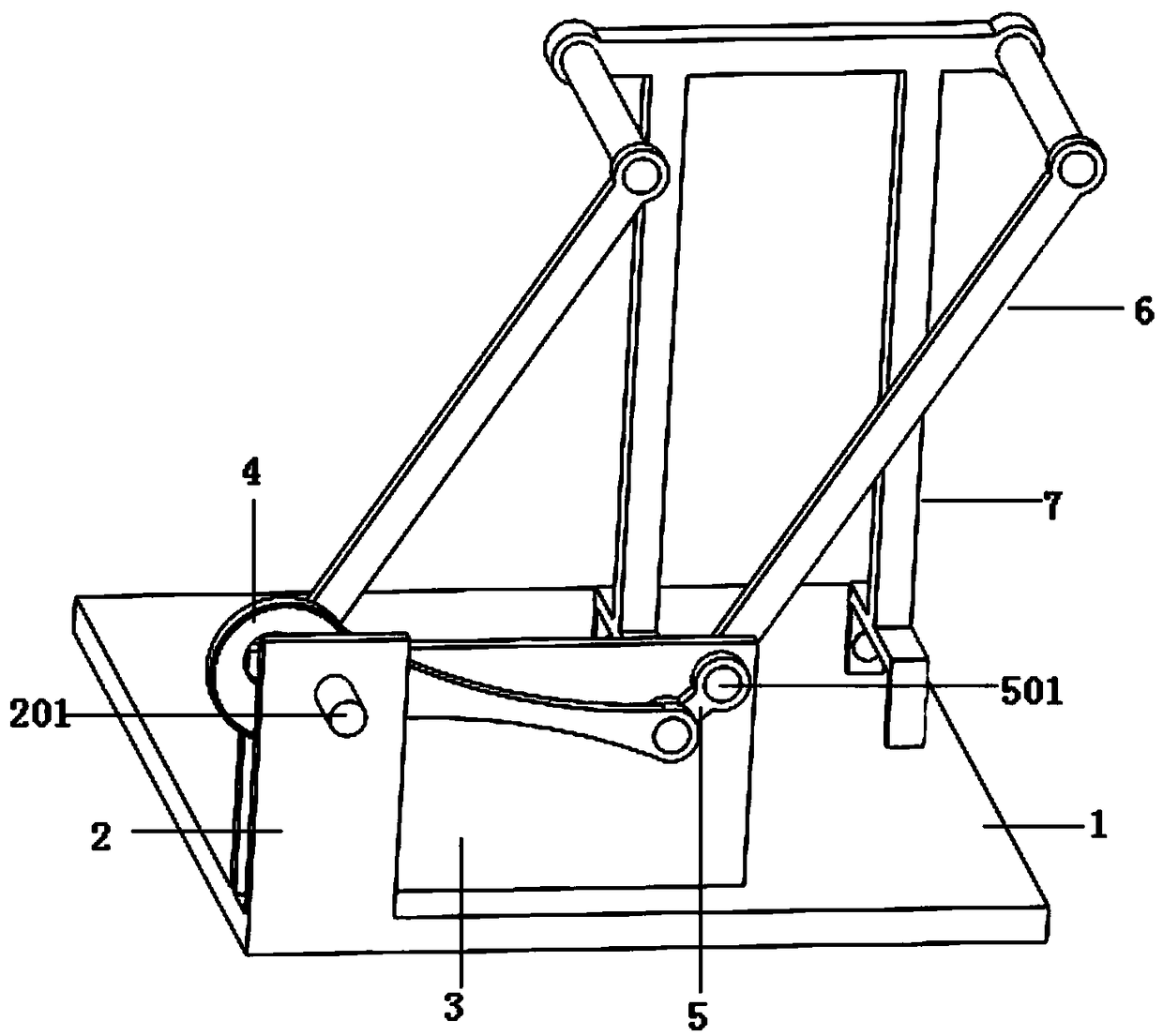

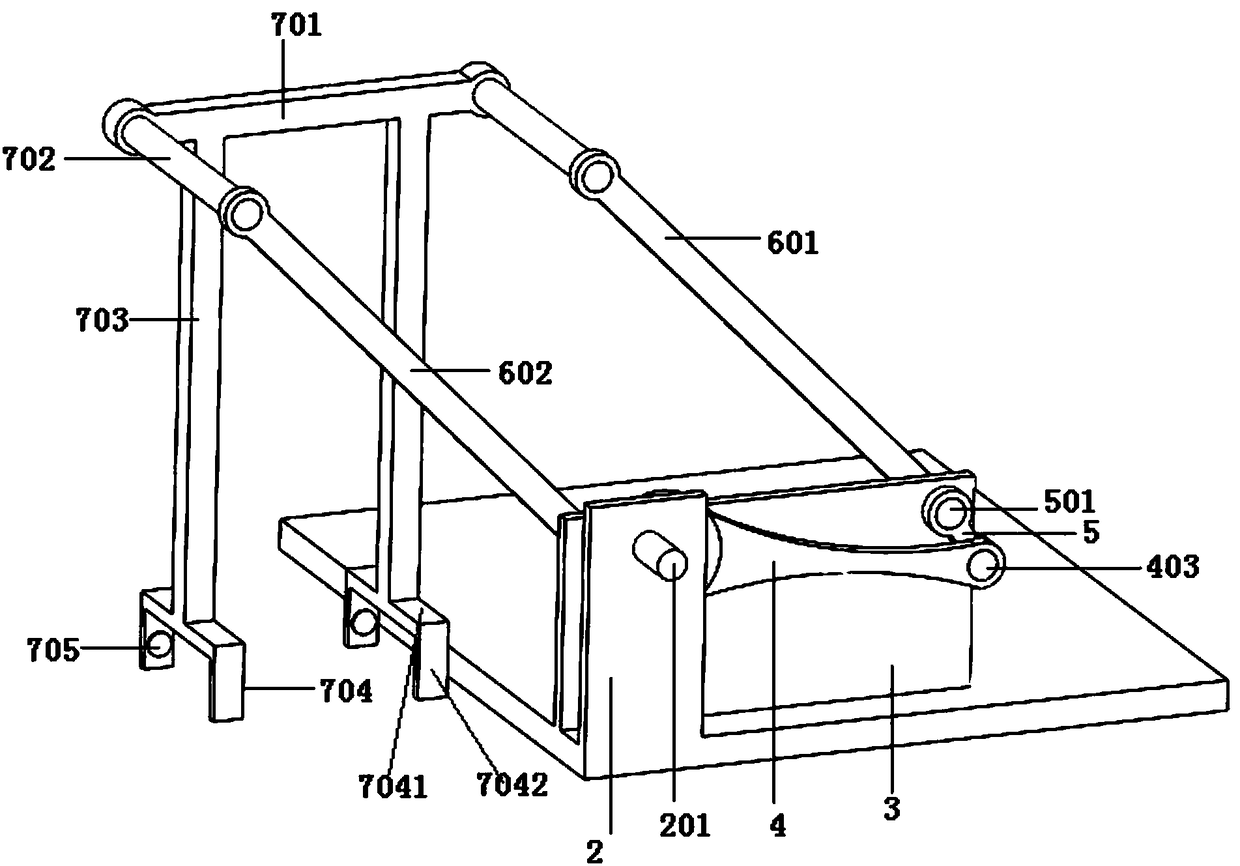

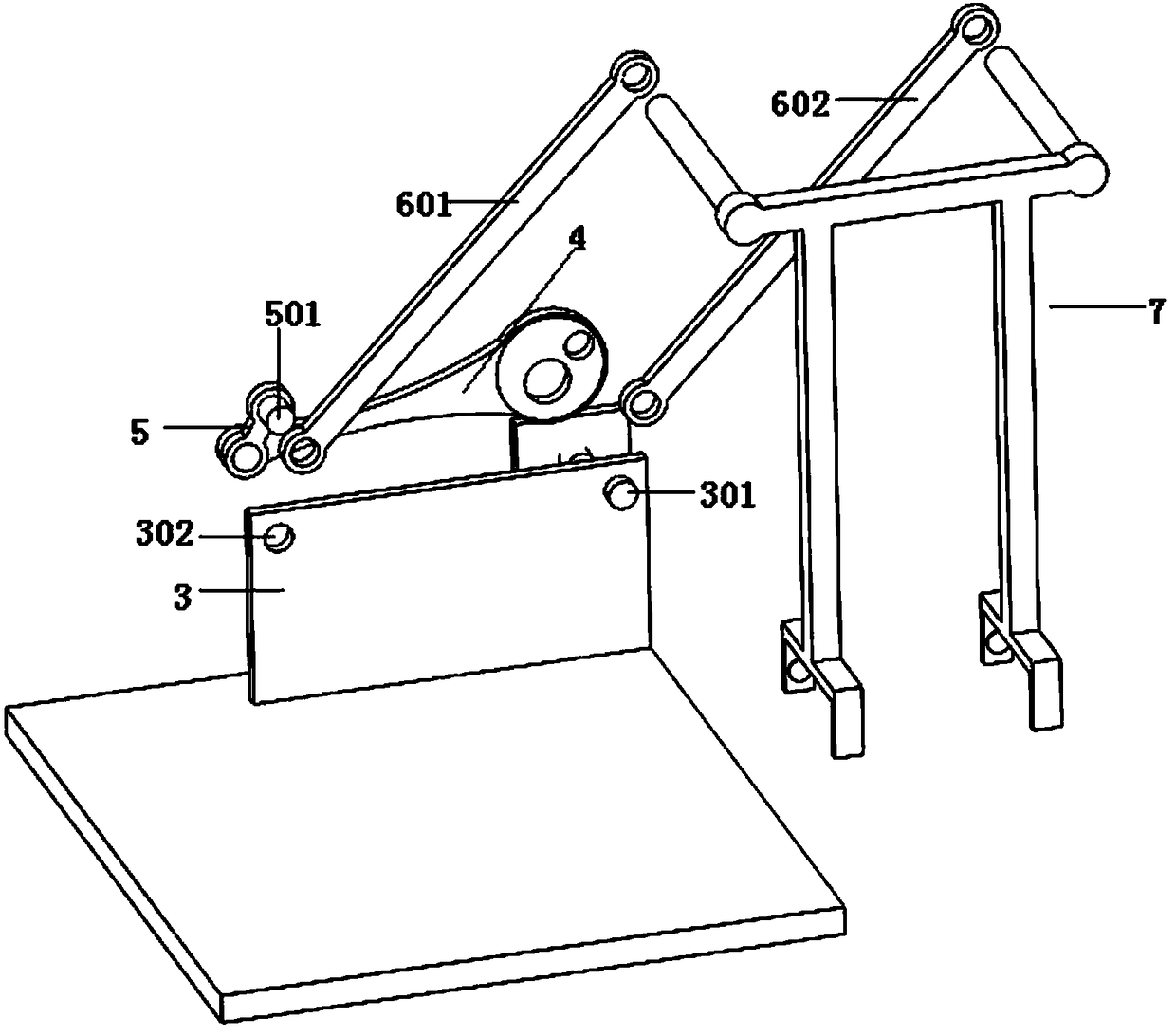

[0020] A fully automatic investment wax injection device, such as figure 1 , figure 2 and image 3 As shown, it includes a transportation manipulator, which is fixed on a horizontal wax injection platform 1. One side of the wax injection platform 1 is connected to the input conveyor belt, and the other side is connected to the output conveyor belt. The input conveyor belt transfers the wax mold base. On the wax injection platform 1, after the wax mold base is injected on the wax injection platform 1, the wax mold base after wax injection is taken and placed on the output conveyor belt by the transportation manipulator, and then transported to the next casting process through the output conveyor belt, The continuous production process of investment casting can be realized without manpower replacement of casting equipment;

[0021] The transportation manipulator includes a first positioning plate 2 and a second positioning plate 3 that are vertically distributed and oppositel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com