Engine water pump cover bolt filling device

A technology for filling devices and water pump covers, which is applied in manipulators, program-controlled manipulators, metal processing, etc., can solve problems such as increased production costs and production time, inability to meet mass production requirements, and low work efficiency, so as to reduce labor intensity and manufacture Cost, ingenious structural design, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

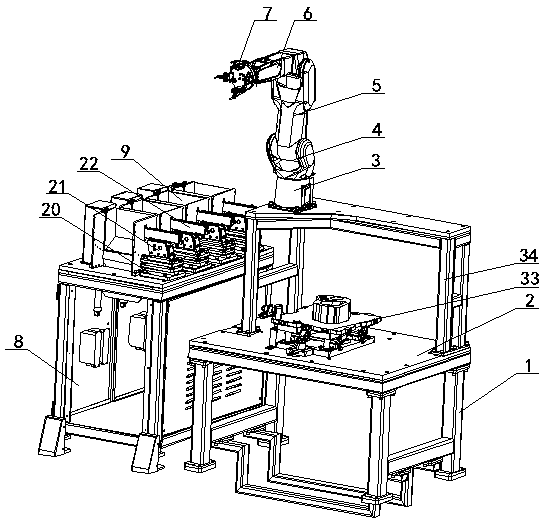

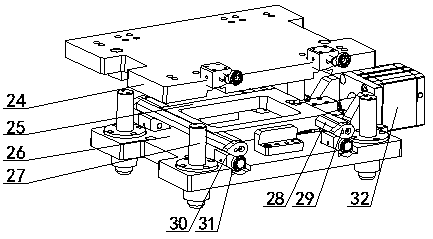

[0017] Embodiment 1: as figure 1 , 2 Shown, a kind of engine water pump cover bolt filling device, described device comprises frame 1, is provided with installation platform 2 in the middle part of described frame 1, is provided with positioning lifting mechanism on described installation platform 2, in described One side of the upper end surface of the frame 1 is provided with a bracket 34 , a handle mechanism is arranged on the support 34 , and a bin device is arranged outside the frame 1 and corresponding to the handle mechanism.

[0018] Wherein, the handle mechanism includes a base 3, on which a first arm 4, a second arm 5 and a third arm 6 that are movably connected in turn are arranged, and one end of the first arm 4 is movable with the base 3 connected, a handle 7 is provided at one end of the third arm 6 .

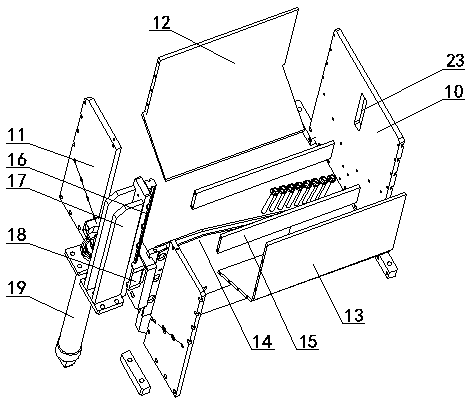

[0019] Further, the silo device includes a cabinet 8, and a plurality of rectangular silos 9 are arranged side by side on the upper end surface of the cabinet 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com