Multi-layer investment casting combination suspension fixture

A multi-level, investment technology, applied in the field of investment casting, can solve the problems of inconvenience in picking and placing castings, expanding storage space, occupying space, etc., to achieve the effect of convenient and convenient placement, satisfying load space, and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

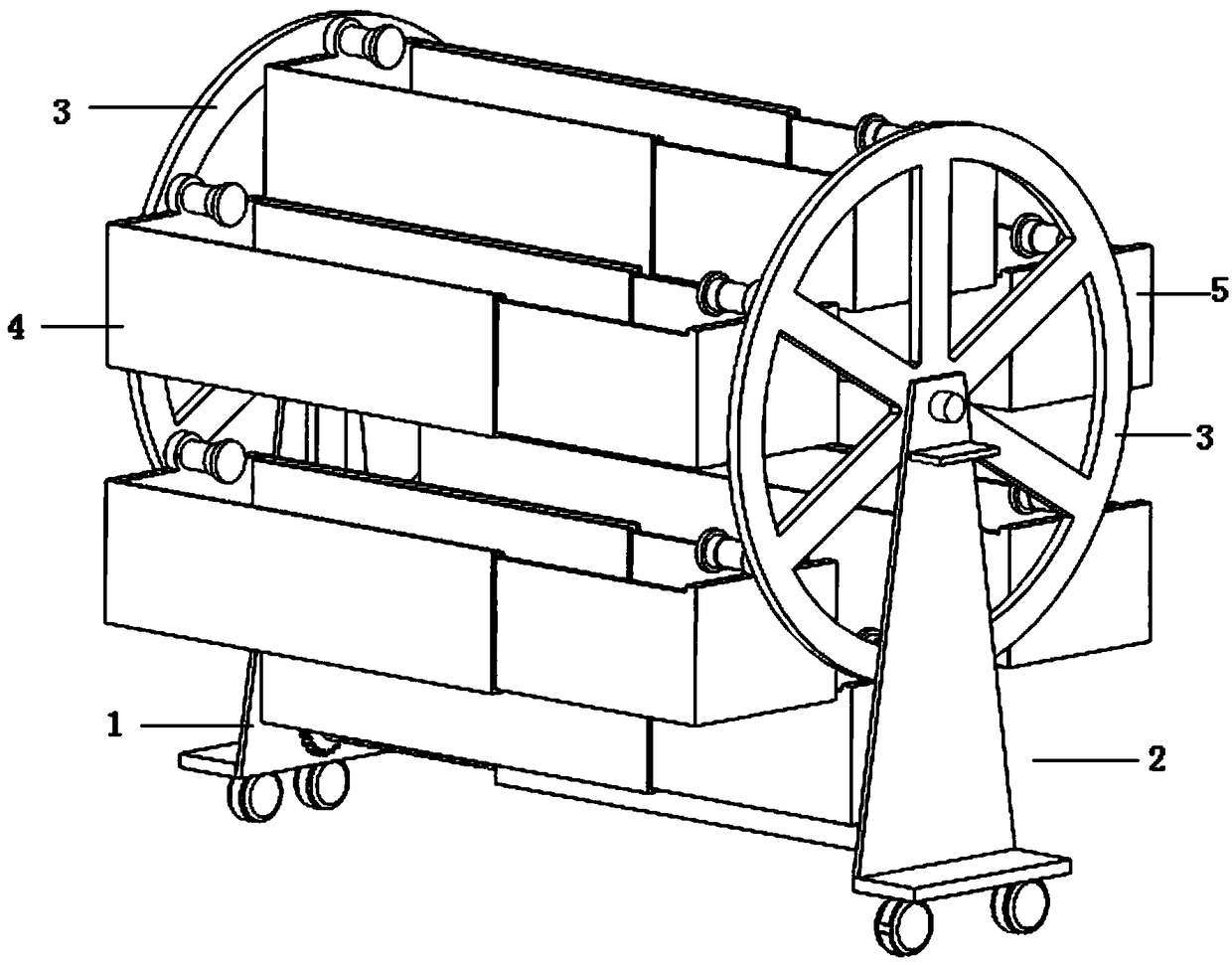

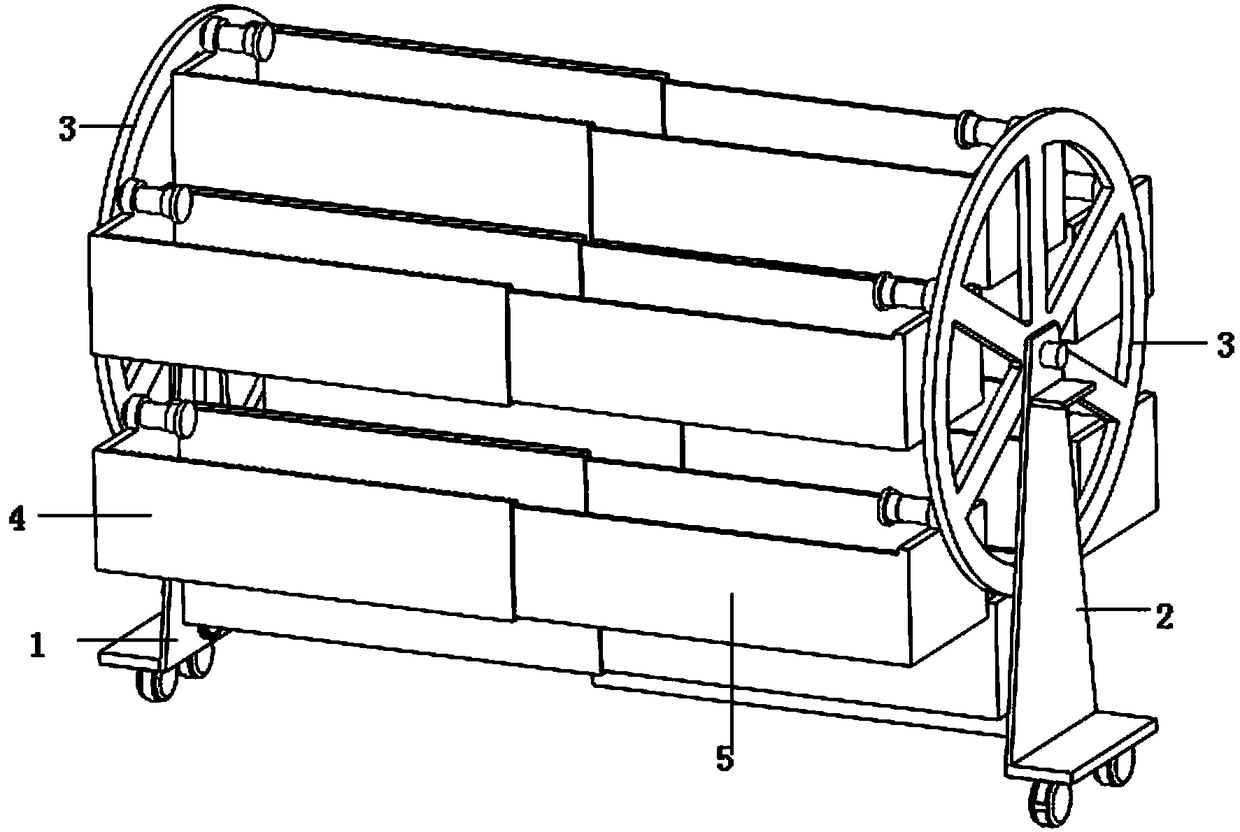

[0026] A multi-level investment casting combined suspension tooling, such as figure 1 with figure 2 As shown, a first support mechanism 1 and a second support mechanism 2 are included, and a rotation fixing mechanism 3 is installed and fixed on the first support mechanism 1 and the second support mechanism 2, and the rotation of the first support mechanism 1 and the second support mechanism 2 A first carrying mechanism 4 and a second carrying mechanism 5 are mounted on the fixing mechanism 3 at equal angles respectively, and the first carrying mechanism 4 is plugged and fixed in the second carrying mechanism 5;

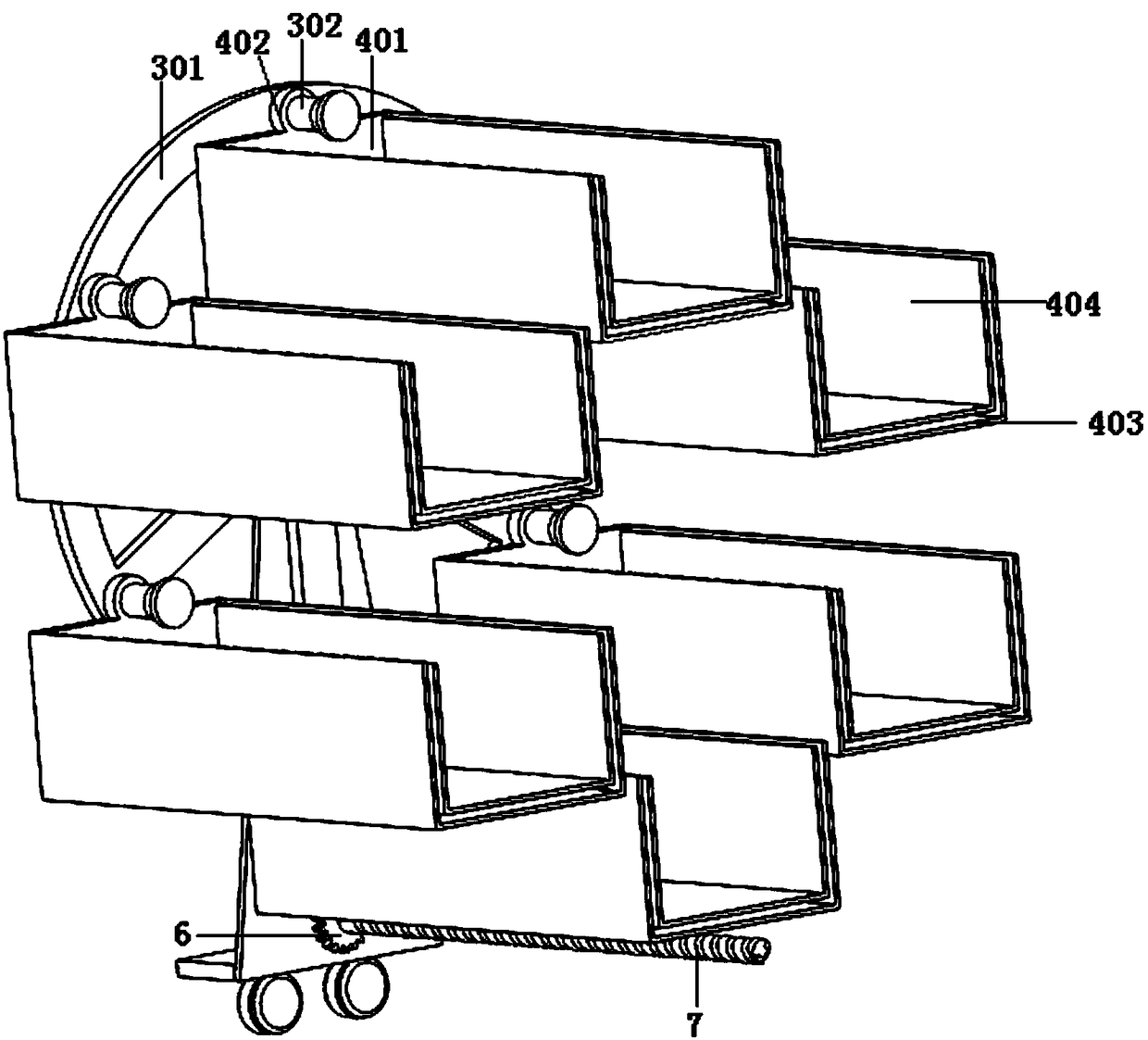

[0027] Such as image 3 , Figure 4 , Image 6 with Image 6 As shown, the first support mechanism 1 includes a first base plate 101 and a vertically distributed first support plate 102 fixed on one side of the surface of the first base plate 101. The top end of the side wall of the first support plate 102 is fixed with a first A rotating shaft 105, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com