Air conditioner manifold branch air pipe production method and mold adopted by air conditioner manifold branch air pipe production method

A production method and air pipe technology, which is applied in the production of air-conditioning branch pipes and the field of molds used, can solve the problems of easy deformation of air-conditioning branch pipe blanks, the inability to perform ultrasonic welding, and high production costs, so as to save storage and transportation links , high yield and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

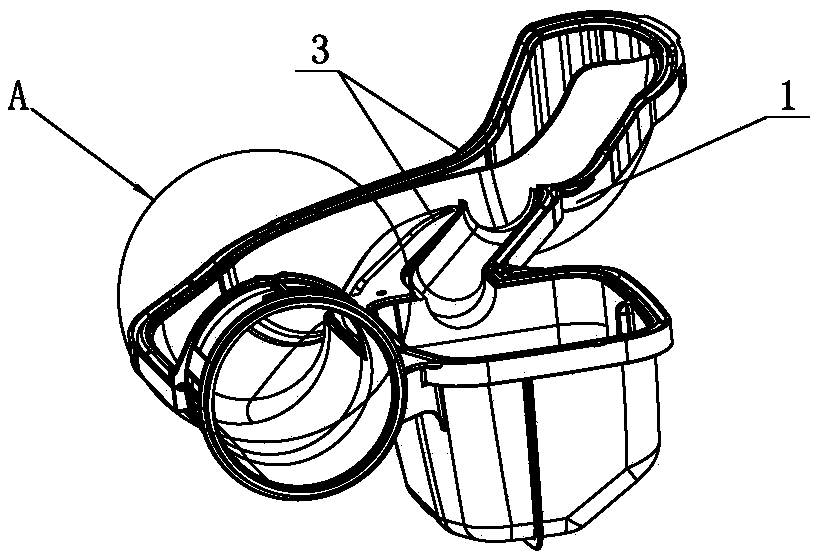

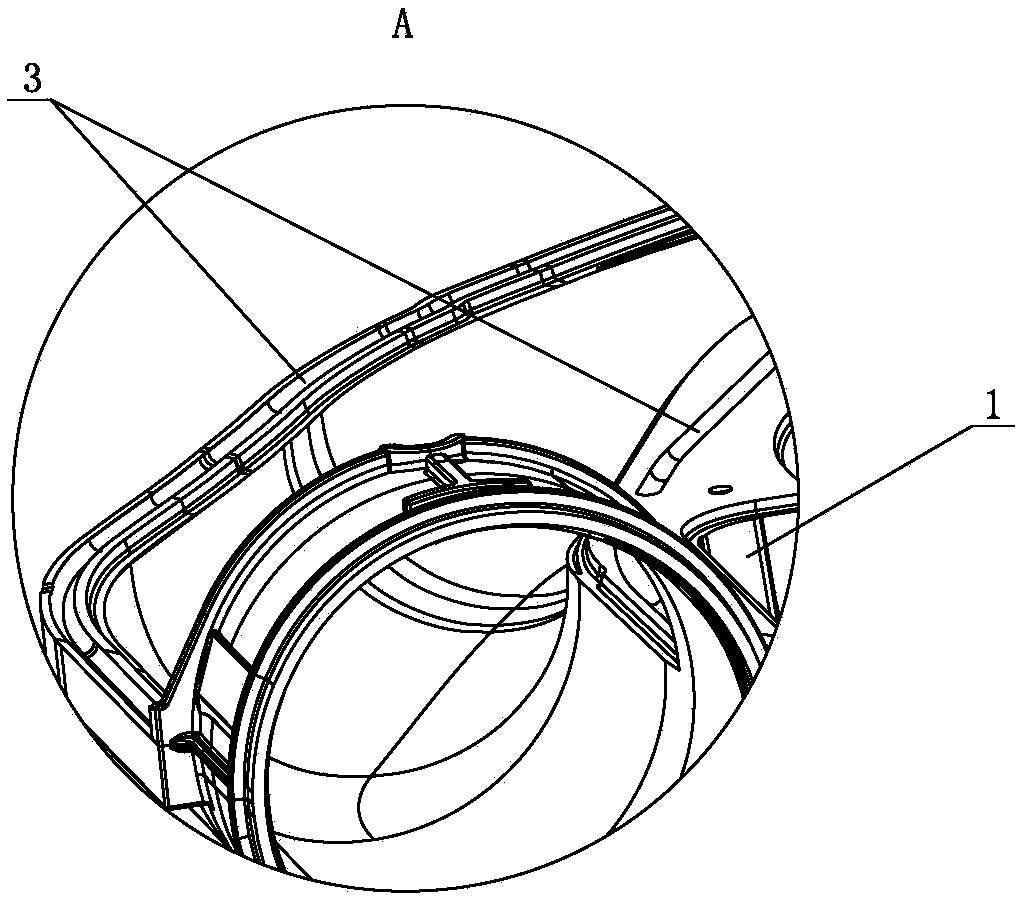

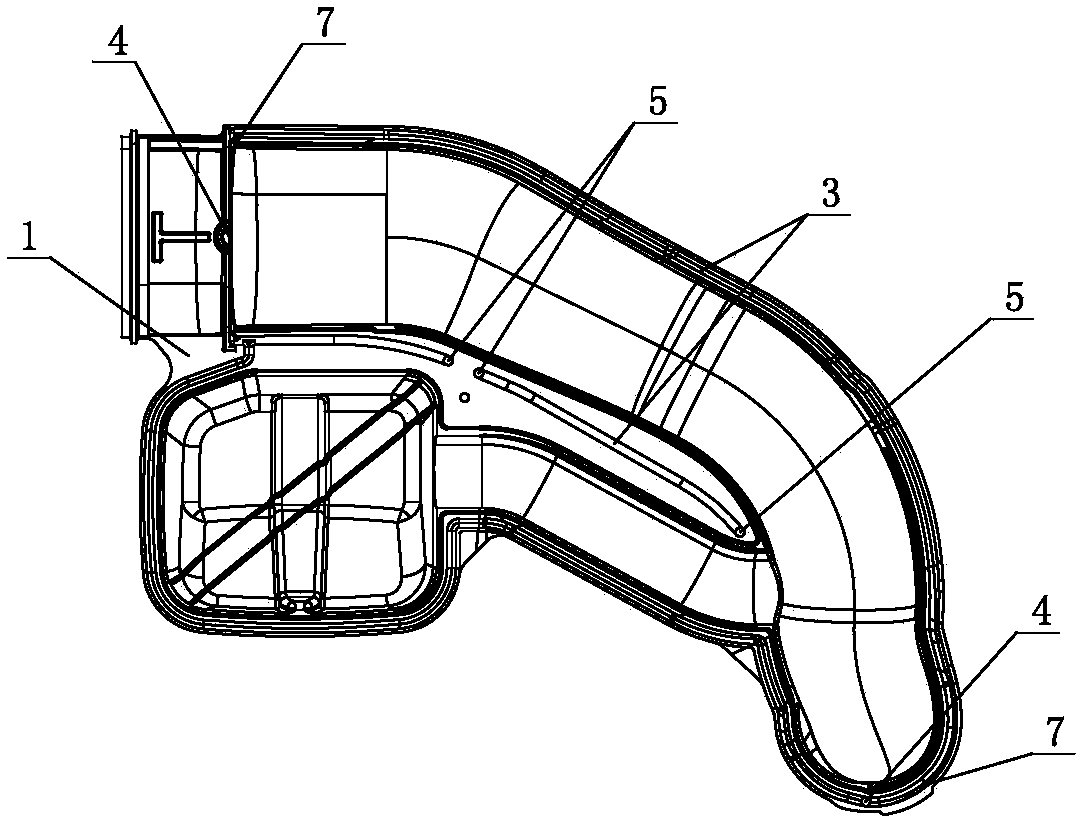

[0033] Such as Figure 1-6 As shown, the present invention provides a kind of air-conditioning bronchial production method,

[0034] The air-conditioning branch manifold is divided into a first blank 1 and a second blank 2 along the thickness direction, and the first blank 1 and the second blank 2 are injection molded respectively. First, the first blank 1 and the second blank 2 of the air-conditioning branch There are elongated grooves 3 on the bonding surface and the bonding surface of the second blank 2 and the first blank 1, and the groove 3 on the first blank 1 is opposite to the groove 3 on the second blank 2 Arrangement, the bonding surface of the first blank 1 and the middle part of the second blank 2 is also provided with a strip-shaped groove 3, and the two ends of the groove 3 positioned on the bonding surface of the middle part are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com