Method for direct ink-jet printing of short channel electrodes

An inkjet printing, short channel technology, applied in the direction of copying/marking method, printing, etc., can solve the problem of poor droplet ejection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

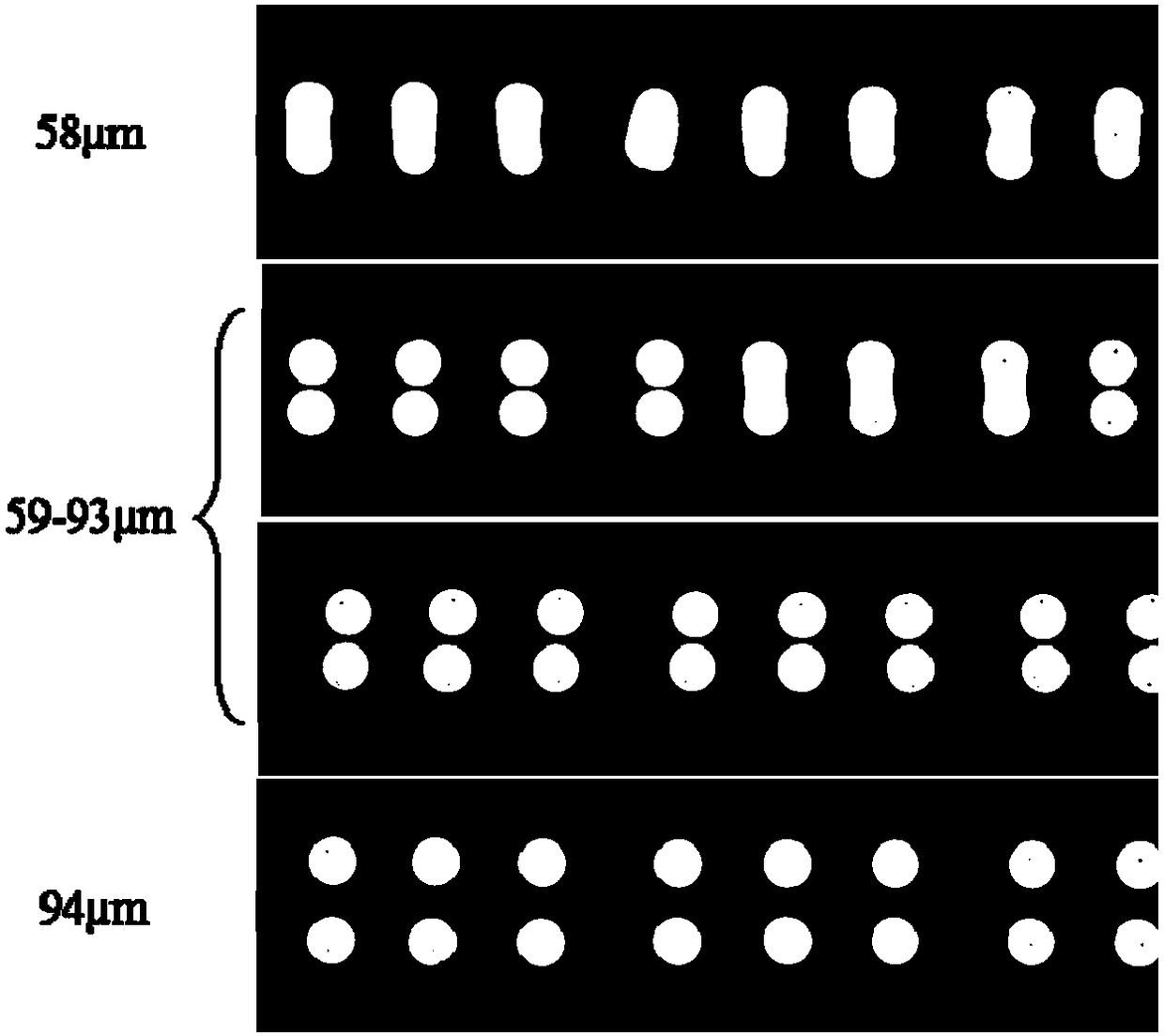

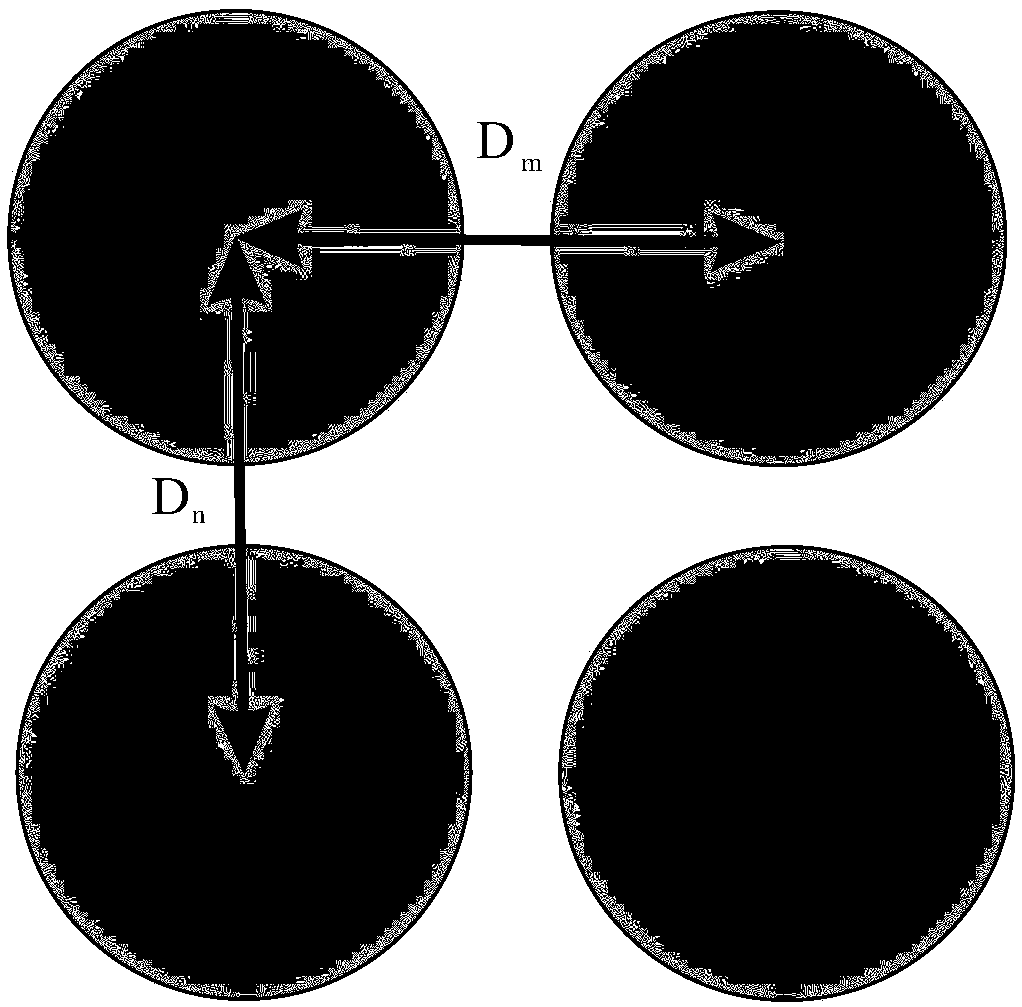

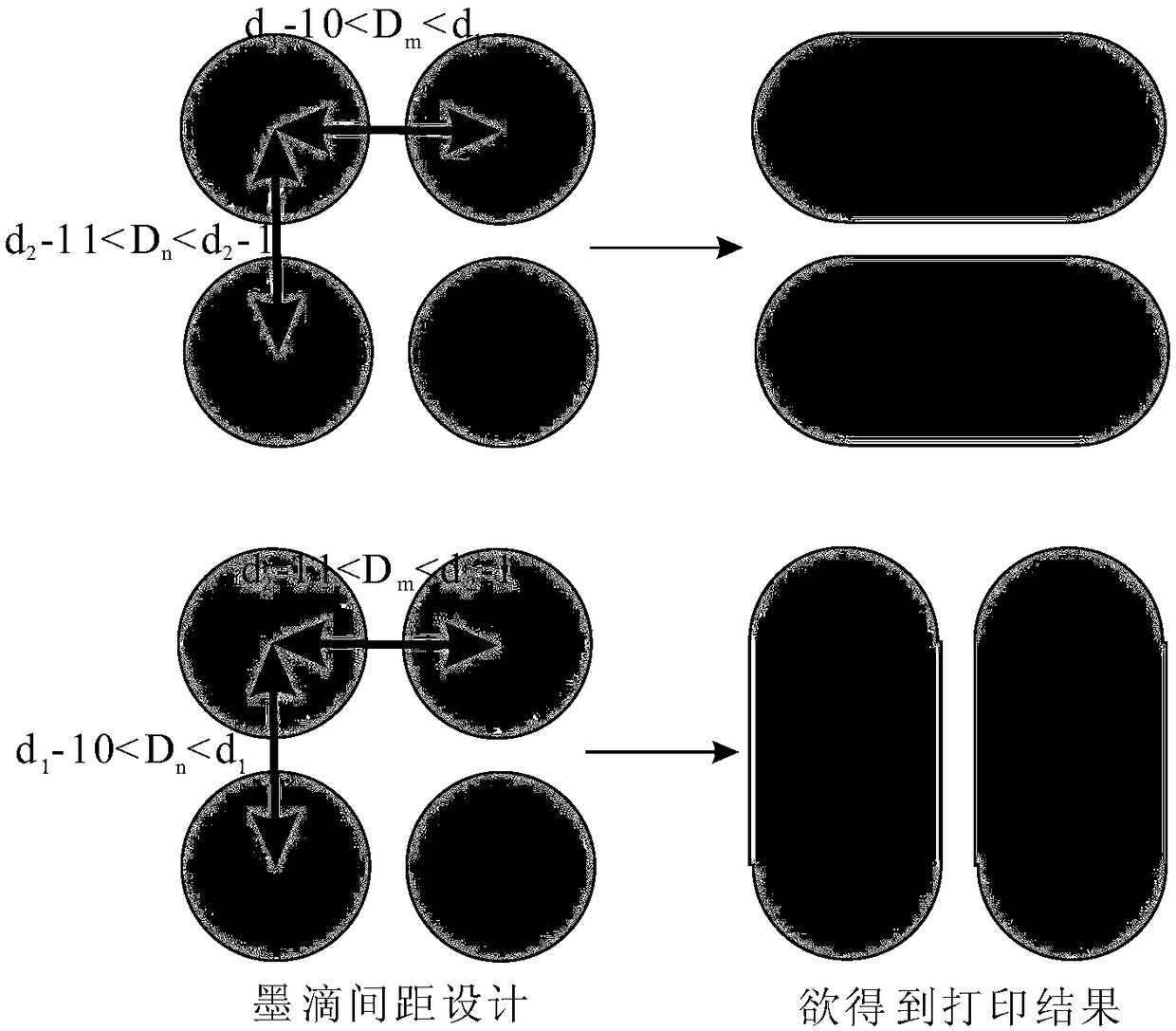

[0033] 1.1. Use granular silver ink (DGP-45LT-15C, Advanced Nano Products, South Korea) for droplet printing. Two droplets are used as a group to print droplet groups with different spacing. The distance between two adjacent droplets is at Between 58 and 94 μm (multiple groups of droplets with different spacing can be printed for easy observation), the printing parameters are: droplet spacing of 35 μm, ejection rate of 2m / s, substrate temperature of 30°C, and nozzle temperature of 30°C. The fusion rule of two printing droplets perpendicular to the printing direction changes with the increase of the droplet spacing as follows: figure 1 Shown: When the distance between droplets is 58μm (d 1 ) or less, the droplets are all fused; the droplet spacing is between 59 and 93 μm, and the droplets are separated, but at a small droplet spacing, the droplets merge sometimes; the droplet spacing is 94 μm (d 2 ) above, the droplets are all separated, and the distance between the droplets i...

Embodiment 2

[0041] 1, Figure 4 shown with 1.1 ( figure 1) with the same inkjet printing conditions (ink and printing parameters), and the marked value is the droplet distance. The obtained results prove that according to the steps described in Example 1 of the present invention, the short channel electrodes obtained parallel to and perpendicular to the printing direction can be repeated.

Embodiment 3

[0043] 1. Use granular silver ink (DGP-45LT-15C, Advanced Nano Products, South Korea) for short-channel electrode array printing. The printing parameters are: droplet spacing 35μm, jetting speed 2m / s, substrate temperature 30°C, nozzle temperature 30°C, d 1 = 58 μm, d 2 = 94 μm. at minimum d 1 、d 2 Starting from the set value of -1, gradually expand the range within a deviation of 10 μm, with a step size of 1 μm, to find the value that can print short channel arrays. Dm = 53 µm, Dn = 90 µm.

[0044] like Figure 5 As shown, all the channel lengths are less than 10 μm, and the channels are smooth. Figure 5 The SEM photo of B proves that there are no stray solute particles in the middle of the channel, and there is no possibility of short circuit between electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com