A Gear Pump with Reduced Power Loss

A power loss and gear pump technology, applied in the field of machinery, can solve the problems of reducing the working reliability of gears, shortening the service life of gears, and aggravating gear wear, so as to improve tempering stability and tempering temperature, eliminate quenching stress, and improve The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

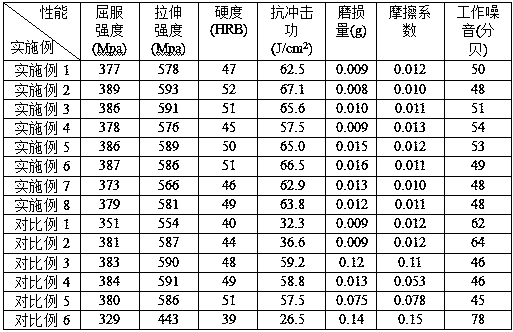

Examples

Embodiment 1

[0029] The gear pump for reducing power loss in this embodiment includes a casing and a gear, and the gear includes a gear base and a wear-resistant layer coated on the gear base.

[0030] Among them, the gear matrix includes the following components by mass percentage: 0.15%C, 0.17%Si, 0.50%Mn, 0.80%Cr, 0.6%Ni, 0.5%Cu, 0.1%Ag, 0.1%Gd, 0.01%P, 0.01% %S, 0.03% Mo, 5.5% silicate whiskers, 3.6% porous calcium carbonate, the balance is Fe, the length of silicate whiskers is 5-10μm, the aspect ratio is 20-35, the porous calcium carbonate The particle size is 2-5μm, and the pore size is 20-38nm.

[0031] The thickness of the wear-resistant layer is 6 μm, which is formed by coating the gear substrate with wear-resistant emulsion. The wear-resistant emulsion includes the following components in mass percentage: 36% PVC emulsion, 5.0% nano-Si 3 N 4 , 6.3% chromium oxide, 7.0% silane coupling agent, 10% porous chitosan microspheres, 0.3% active agent lecithin, the balance is distilled...

Embodiment 2

[0034] The difference from Example 1 is that the gear matrix in this example includes the following components by mass percentage: 0.2%C, 0.28%Si, 0.7%Mn, 0.9%Cr, 0.8%Ni, 0.6%Cu, 0.3%Ag, 0.2%Gd, 0.02%P, 0.02%S, 0.06%Mo, 6.5% silicate whiskers, 4.3% porous calcium carbonate, the balance is Fe, the length of silicate whiskers is 5-10μm, the aspect ratio 20-35, the particle size of porous calcium carbonate is 2-5μm, and the pore size is 20-38nm.

Embodiment 3

[0036]The difference from Example 1 is that the gear matrix in this example includes the following components by mass percentage: 0.2%C, 0.28%Si, 0.7%Mn, 0.9%Cr, 0.8%Ni, 0.6%Cu, 0.4%Ag, 0.2%Gd, 0.02%P, 0.02%S, 0.06%Mo, 6.5% silicate whiskers, 4.3% porous calcium carbonate, the balance is Fe, the length of silicate whiskers is 5-10μm, the aspect ratio 20-35, the particle size of porous calcium carbonate is 2-5μm, and the pore size is 20-38nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com