Pumping unit brake assembly

A pumping unit and assembly technology, which is applied in the field of pumping unit brake assembly, can solve the problems of difficult pumping unit shutdown attitude adjustment again, difficult adjustment of pumping unit shutdown attitude, poor attitude adjustment accuracy, etc., to achieve saving Remove the brake safety device, avoid the car from slipping, and ensure the effectiveness of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

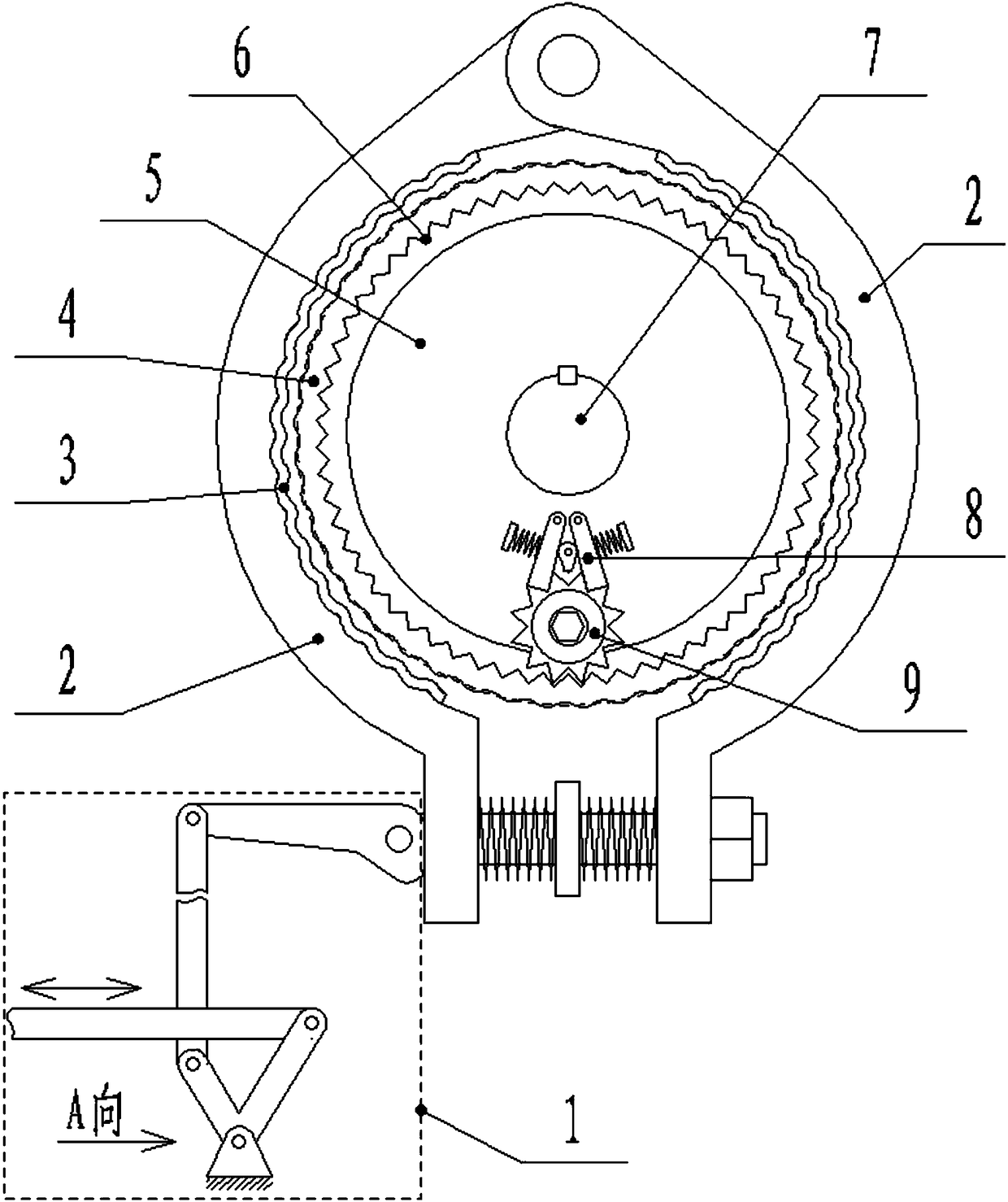

[0017] The present invention will be further described below in conjunction with accompanying drawing:

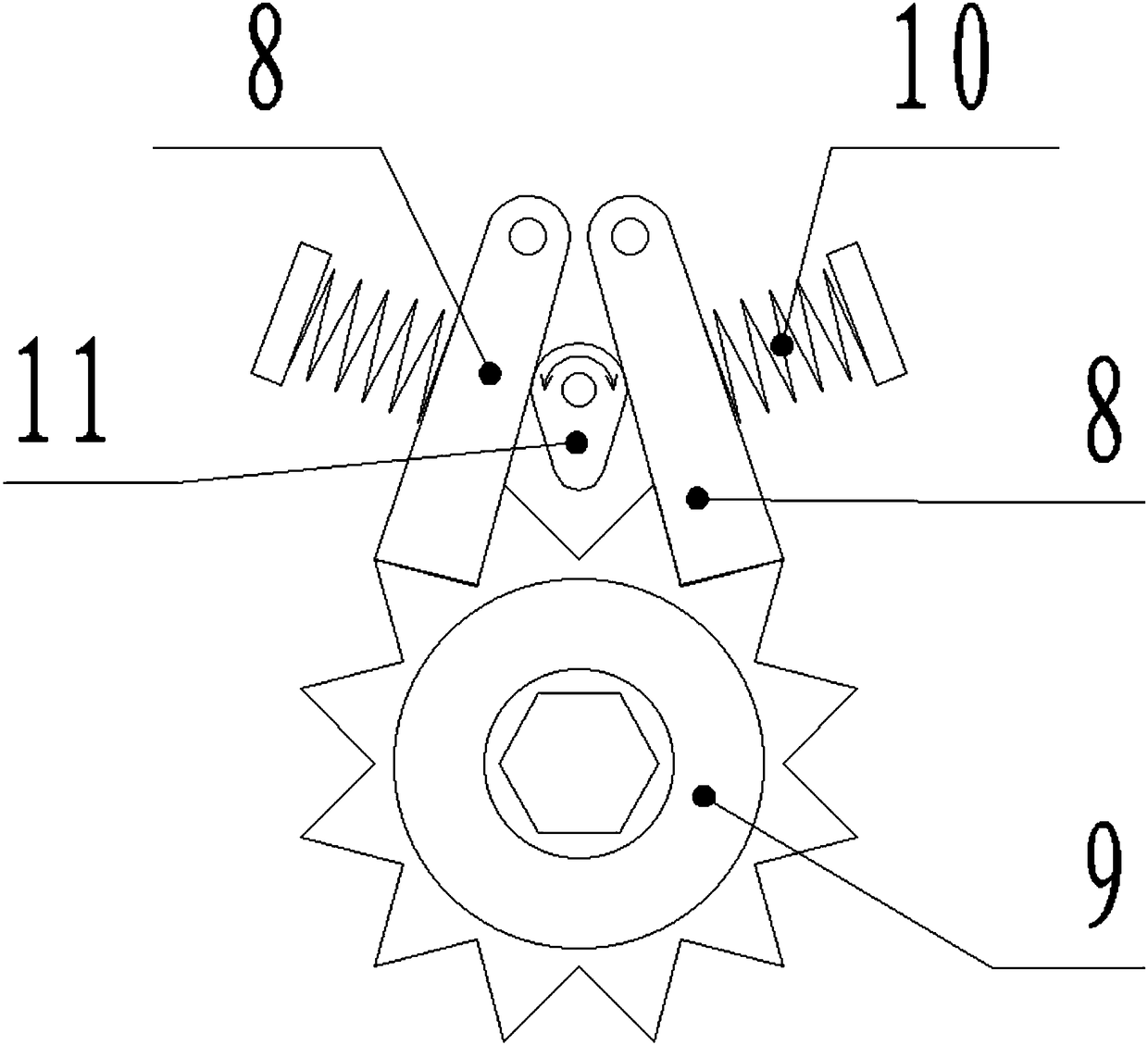

[0018] The present invention includes a brake unit and a link control mechanism 1, the brake unit is provided with a brake wheel and a clamp arm 2, the brake wheel is fixedly installed on the brake shaft 7 that needs to be braked, and there are two clamp arms 2 , the two clamp arms 2 are hingedly connected to form a ring structure with an opening, and the inner side of the clamp arm 2 is fixed with a brake pad 3. When braking, the two clamp arms 2 will brake from the outside under the drive of the linkage control mechanism 1. The wheel is locked to achieve the braking of the brake wheel, that is, the braking of the pumping unit. The above are common structures in the prior art, and will not be repeated here.

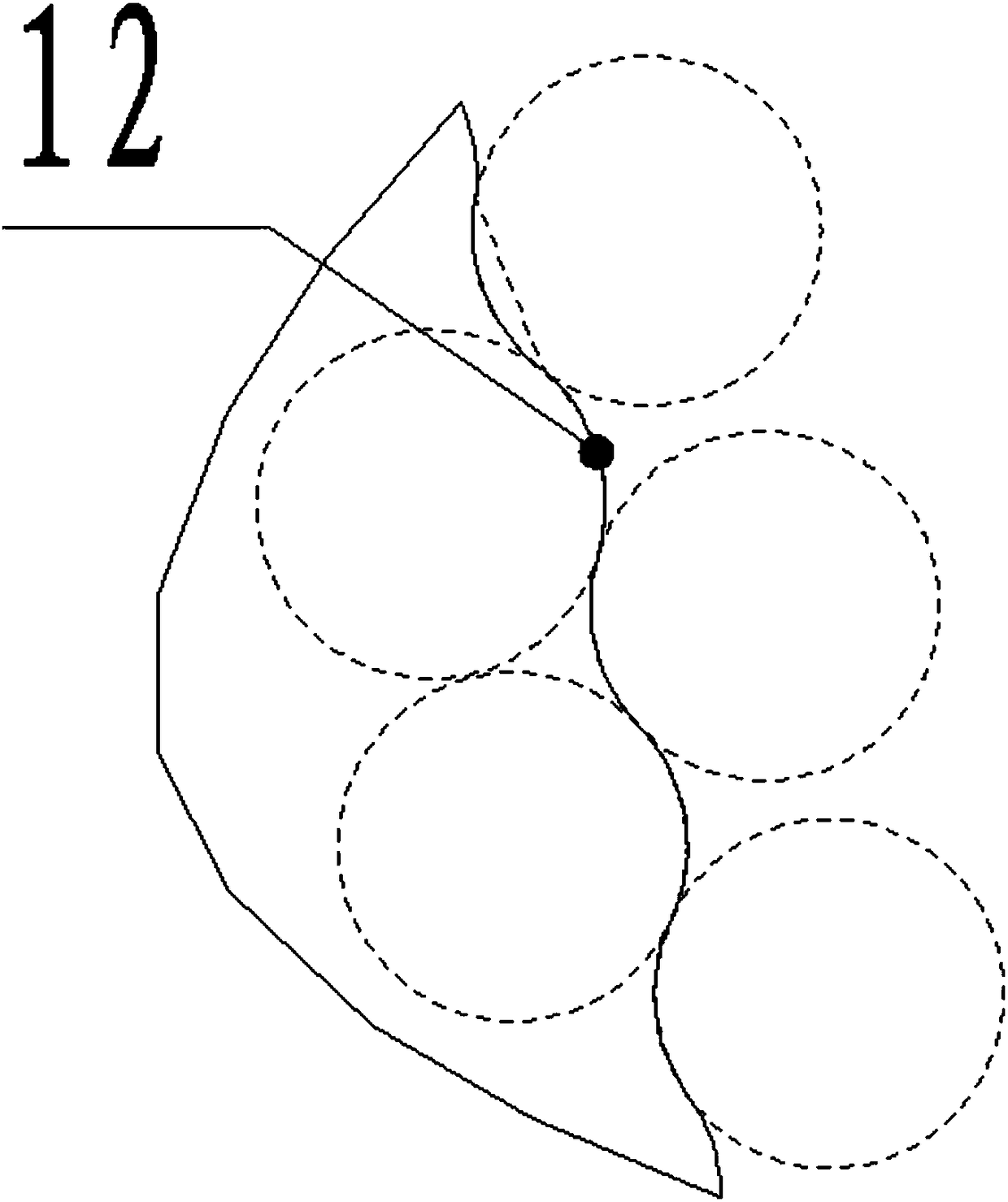

[0019] The brake wheel is divided into inner ring 5 and outer ring 4. The outer ring 4 is sleeved on the inner ring 5 and can rotate around the axis of the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com