A six-degree-of-freedom low-frequency vibration active-passive isolation mechanical device

A low-frequency vibration and mechanical device technology, applied in mechanical equipment, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of limiting the vibration isolation level of the vibration isolation mechanism, and it is difficult to satisfy the vibration isolation device at the same time, so as to achieve enhanced vibration isolation effect , few parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

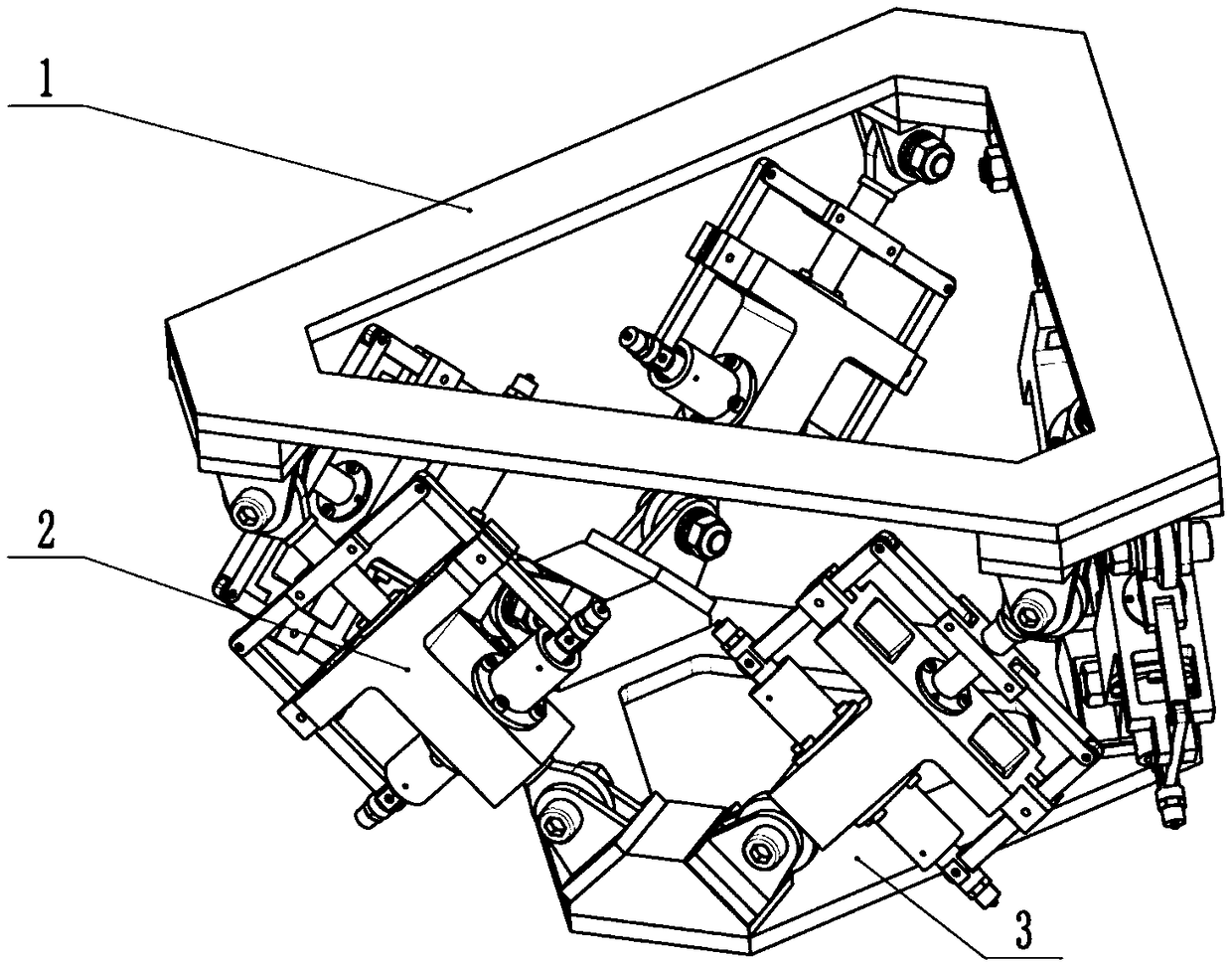

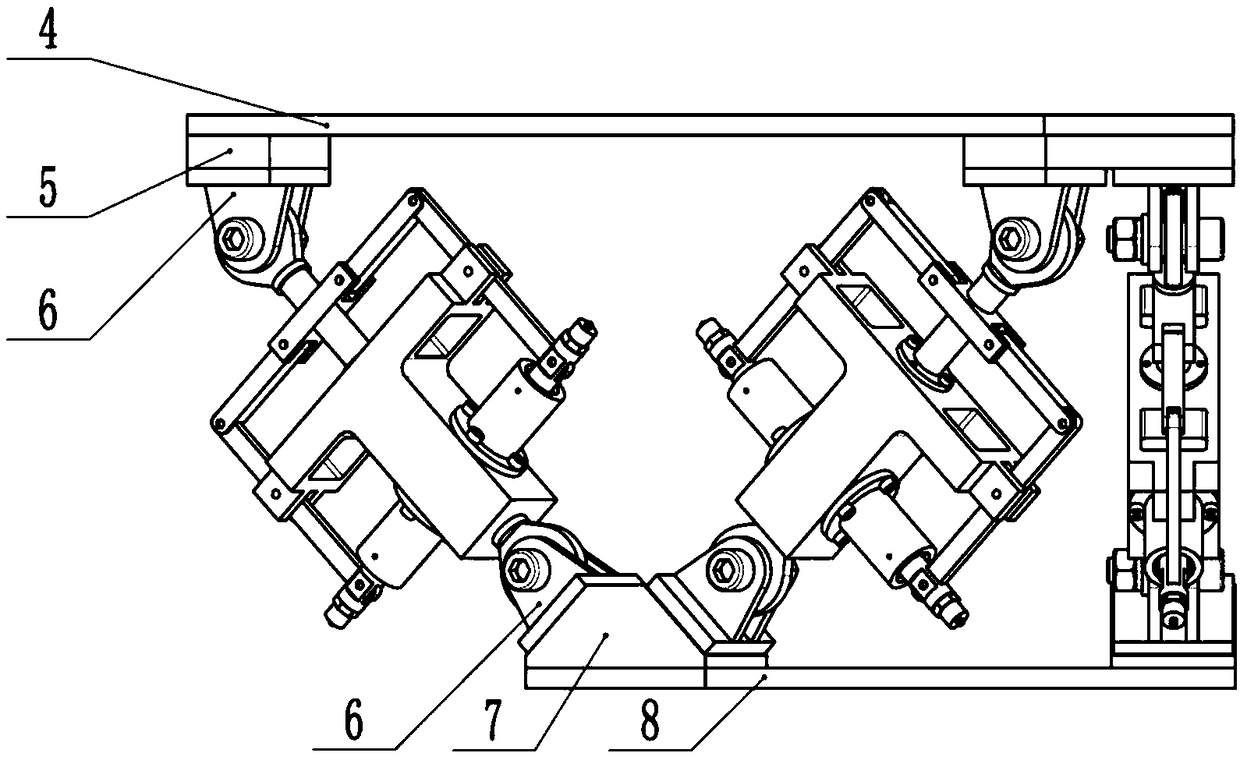

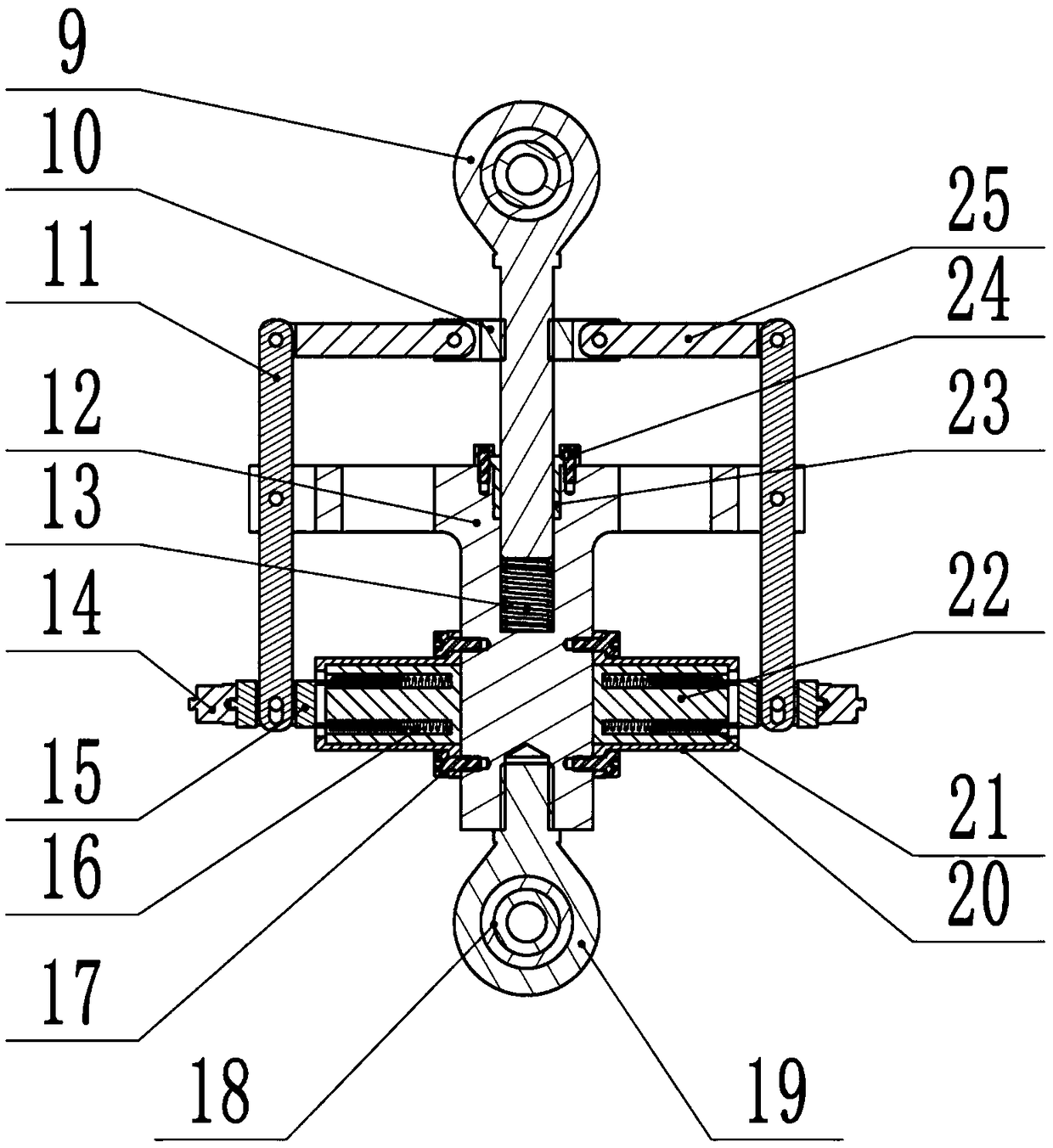

[0037] Such as figure 1 , figure 2 As shown, the present invention is a six-degree-of-freedom low-frequency vibration active and passive isolation mechanical device, which includes a stage 1 , a vibration isolation unit 2 and a base 3 .

[0038] The vibration isolation unit 2 is connected to the stage 1 and the joint bearing support 6 on the base 3, the stage 1 is a platform for placing and fixing high-precision loads, and the base 3 is for connecting and fixing the vibration isolation unit 2 Foundation.

[0039] The stage 1 includes a fixed plate 4, an upper connecting block 5 and a joint bearing support 6, the fixed plate 4 is a hexagonal flat structure, the three long sides are equal in length, the three short sides are equal in length, and the upper connecting block 5 is Hexagonal structure, three upper connecting blocks 5 are respectively fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com