Two-gear transmission mechanism based on gear ring drive

A transmission mechanism and ring gear technology, applied in the transmission field, can solve the problems of small friction force and reduce the transmission efficiency of the transmission mechanism, and achieve the effects of reducing friction loss, compact structure and good practical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

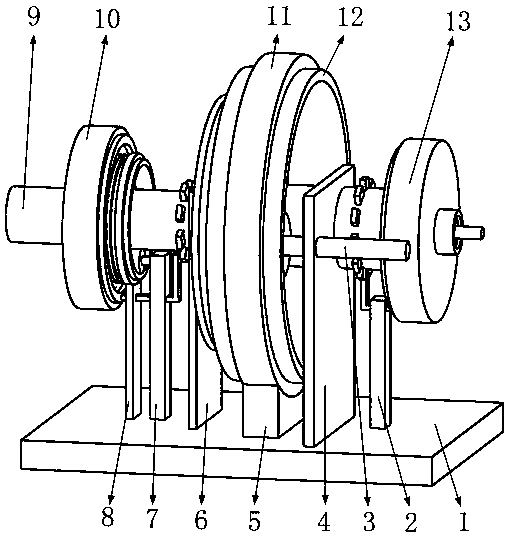

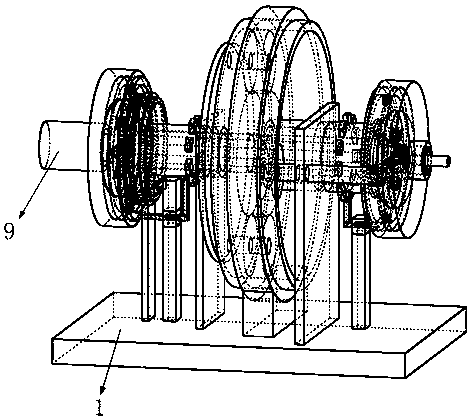

Image

Examples

specific Embodiment approach

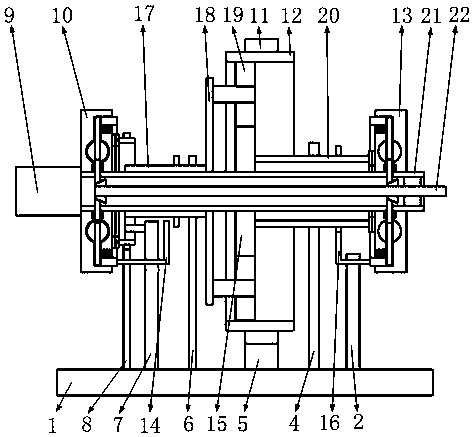

[0061] Specific implementation: when the transmission mechanism is not working, the first L-shaped limiting plate 14 and the first limiting block 24 do not produce a limiting effect; the second L-shaped limiting plate 16 and the second limiting block 33 produce a limiting effect effect.

[0062] When the transmission mechanism is low-speed transmission, the driving gear 23 drives the first ring gear 12 to rotate at a low speed; since the first L-shaped limiting plate 14 and the first limiting block 24 do not produce a limiting effect, the second L-shaped limiting plate 16 and the first limiting block 24 do not produce a limiting effect. The second limiting block 33 produces a limiting effect, then the first planetary gear 19 can rotate freely along the circumferential direction, and the sun gear 15 is stationary; during the low-speed rotation of the first ring gear 12, the first ring gear 12 passes through the second A planetary gear 19, the first disc 18, the first hollow sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com