Automobile illumination lamp

A technology for illuminating lamps and automobiles, which is applied in the direction of motor vehicles, road vehicles, lighting devices, etc. It can solve the problems of occupying space, large environmental pollution, and affecting installation, and achieve the effects of increasing service life, reducing temperature, and strong thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

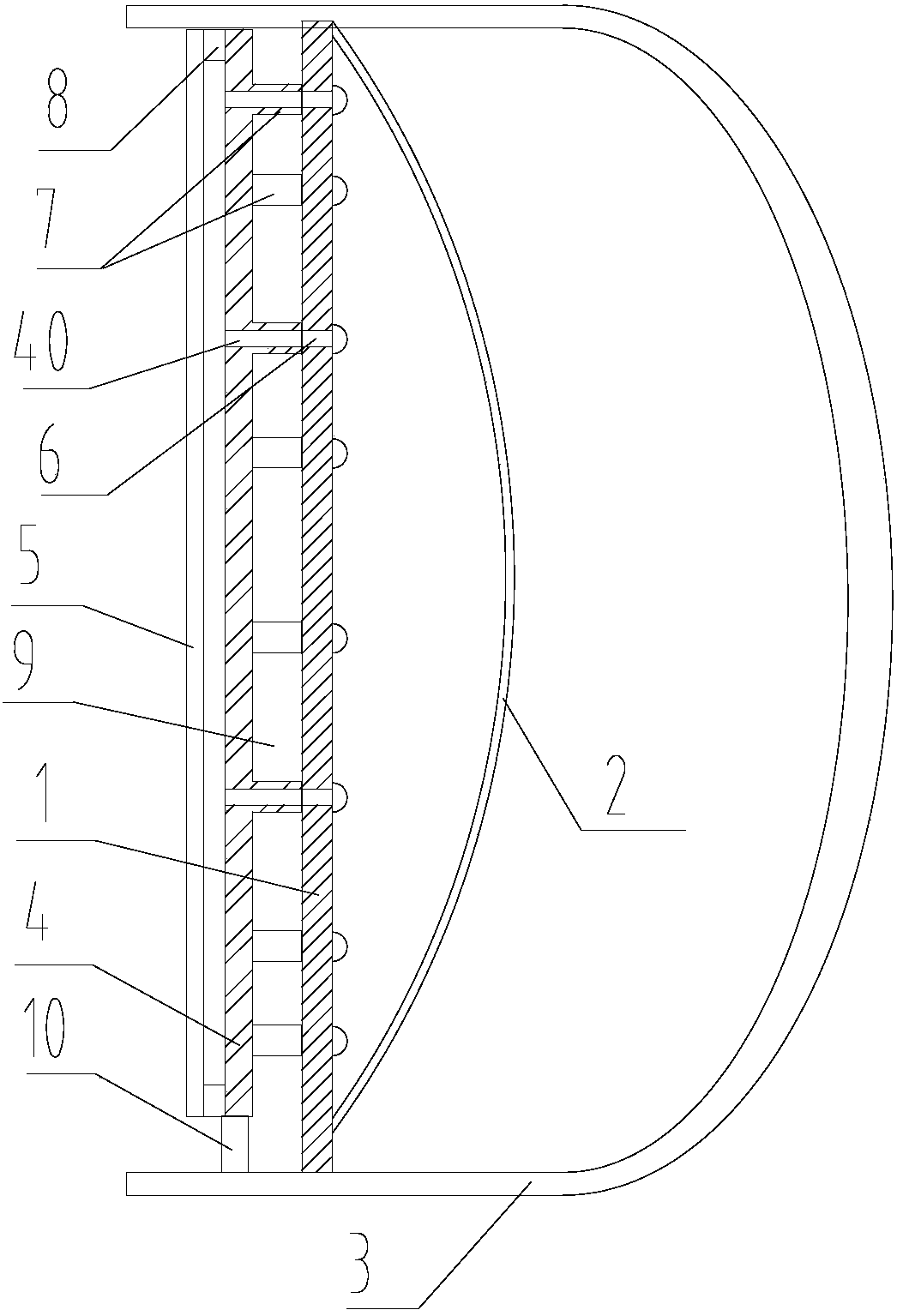

[0016] refer to figure 1 , a kind of automobile illuminating light that the present invention proposes, comprises: base plate 1, diffuser cover 2, lampshade 3, isolation board 4 and PCB board 5.

[0017] The bottom plate 1 is made of a metal plate, and there are a plurality of installation holes corresponding to the LED lights on the bottom plate 1 , and each LED light is installed in the corresponding installation holes 6 through an insulating structure. Specifically, the LED lamp can be installed in the installation hole 6 by dispensing glue. Firstly, the insulating connection between the LED lamp and the metal plate can be realized; secondly, the installation hole 6 can be sealed to ensure the reliable installation of the LED lamp. In this embodiment, an insulating layer is provided in the installation hole 6 to ensure the safety of the LED lamp cable connection.

[0018] The diffuser cover 2 is installed on the base plate 1 and cooperates with the base plate 1 to seal the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com