Phase change support for LED three-dimensional packaging and manufacturing method thereof

A three-dimensional packaging and phase change technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of LED luminous efficiency decline, affecting working life, LED junction temperature rise, etc., to improve light emitting efficiency, improve working life, packaging high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the specific implementation method of the present invention will be further described in detail below with reference to the drawings and examples, but the implementation method of the present invention is not limited thereto.

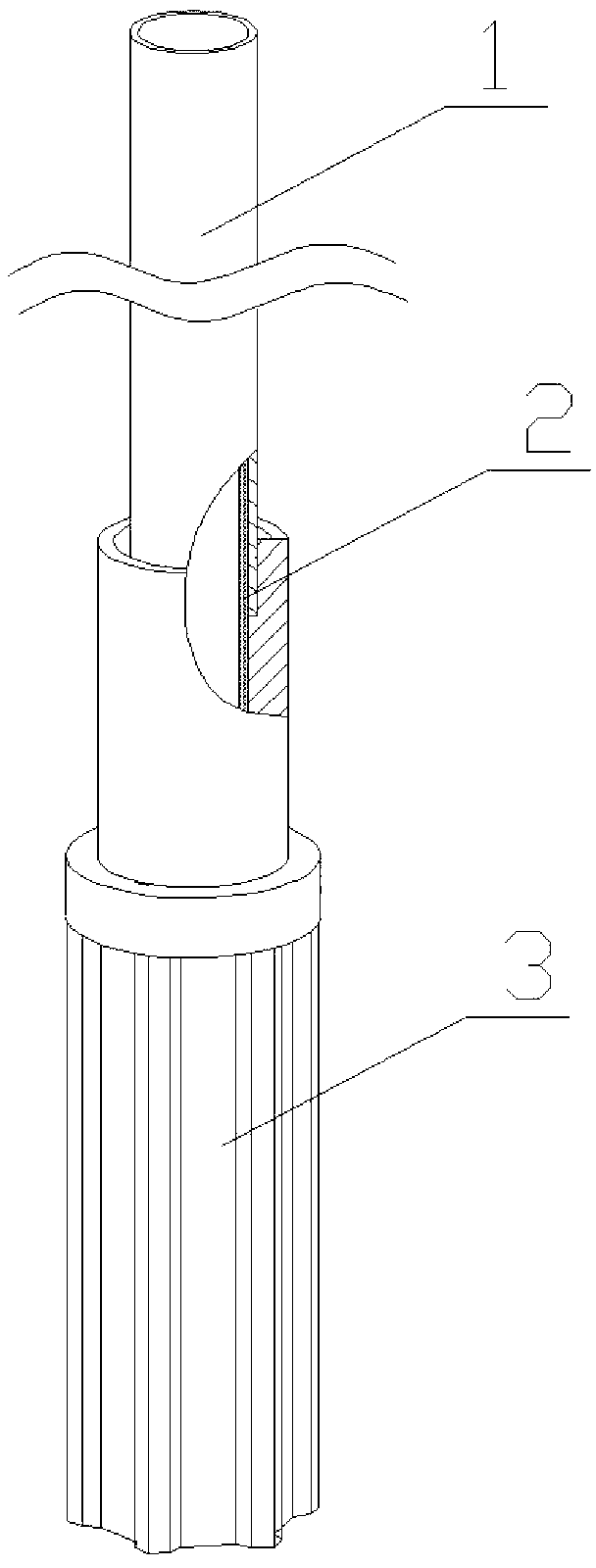

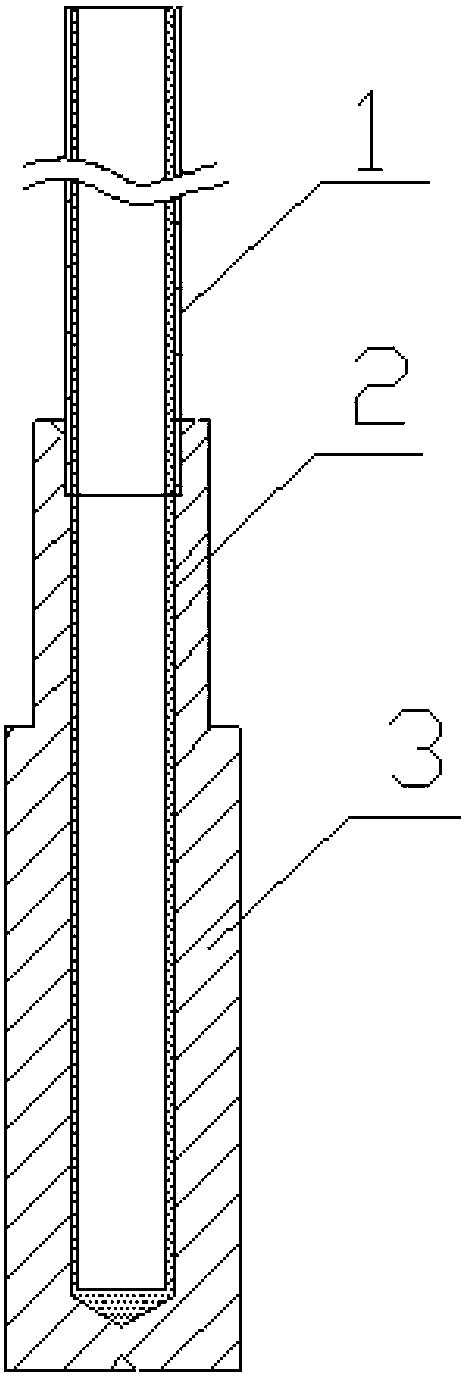

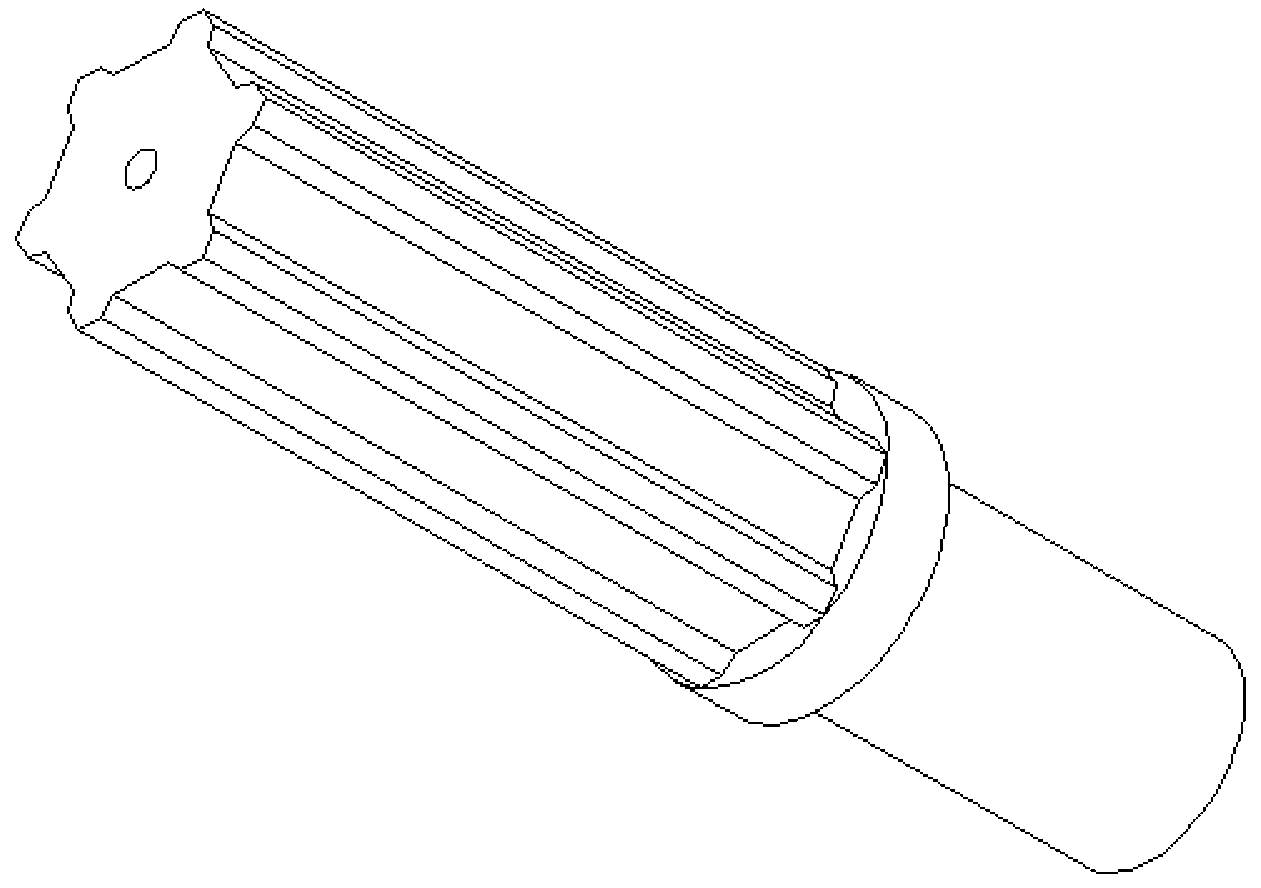

[0031] Such as figure 1 , figure 2 As shown, a phase change bracket for LED three-dimensional packaging includes a bracket base 3 and a copper tube 1; the center of the bracket base 3 is provided with an opening, the front end of the opening runs through the front end of the base, and the front end of the opening is provided with There is a stepped hole, the bottom surface of the hole is 3-8mm away from the bottom surface of the base, the copper tube 1 is inserted into the stepped hole of the hole, and is sealed and matched with the support base by welding; the inner wall of the cavity formed by the support base 3 and the copper tube 1 And the inner wall of the copper pipe 1 is sintered with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com