Rapid air purification and circulation system having waste incineration function

A technology of air purification and garbage incineration, applied in the field of air purification, can solve the problems of single function, slow heating time, large power consumption, etc., and achieve the effect of convenient use and reduction of physical diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

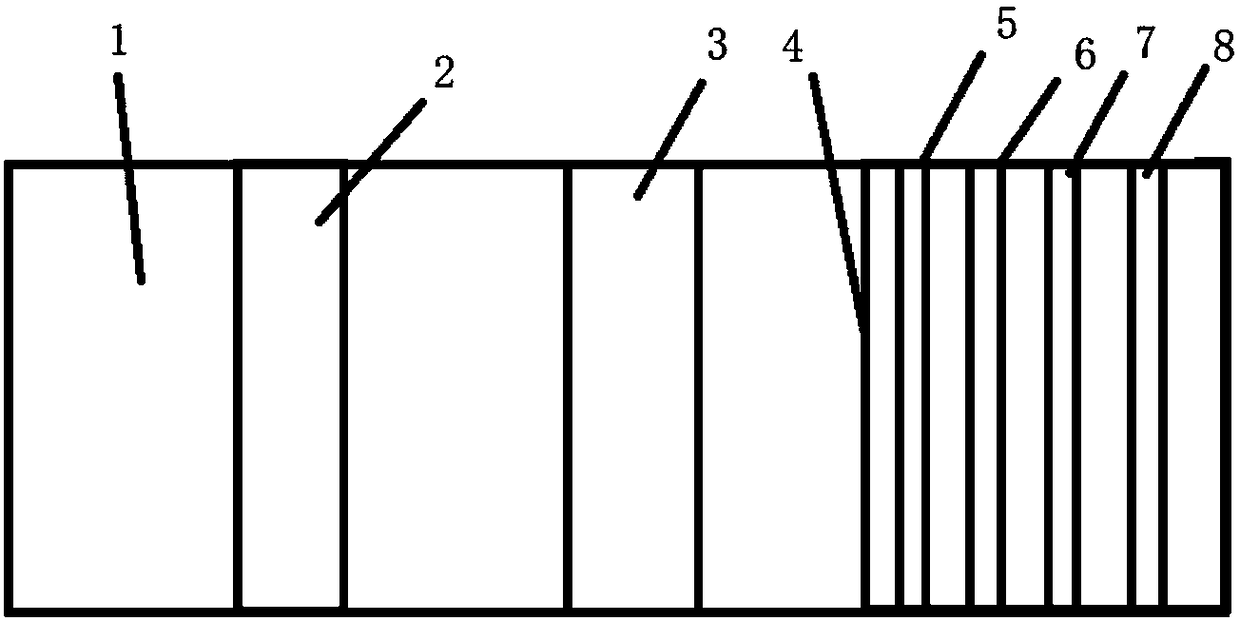

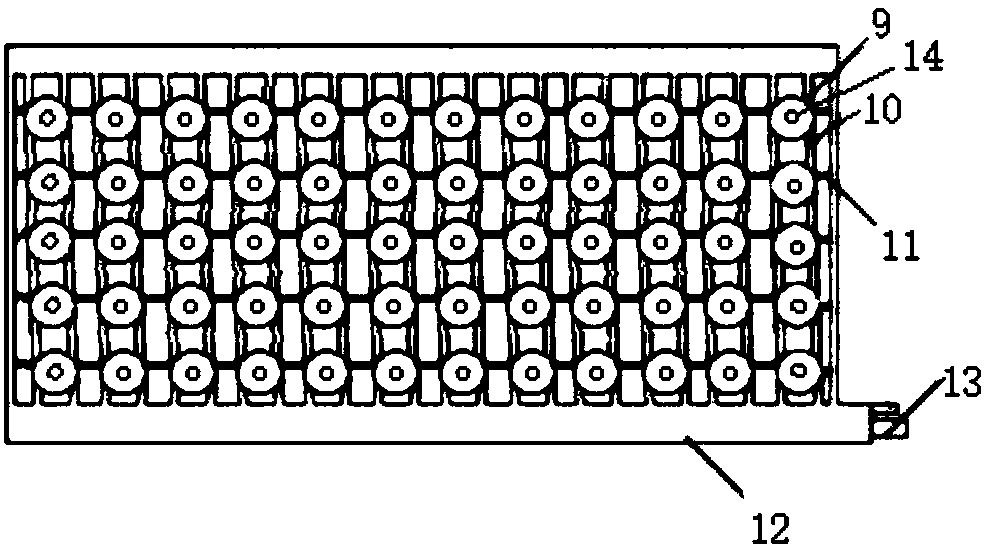

[0025] It is equipped with a waste incineration rapid air purification cycle system, including an air intake bin, a heating device, a photocatalytic device and an air outlet filter device. Connected to the right, the air enters the heating device after passing through the air intake chamber, the heated air enters the photocatalytic device, and the air enters the air outlet filter device after passing through the photocatalytic device Then it is discharged from the air outlet of the air outlet filter device;

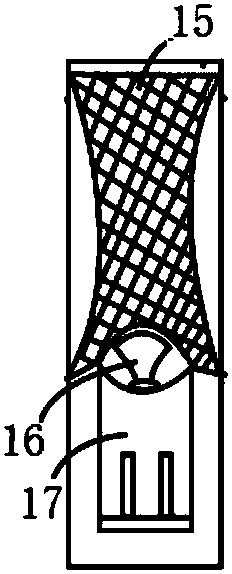

[0026] The photocatalytic device includes a nano photocatalytic net, a plasma generating part and a lamp tube, the lamp tube is arranged above the plasma generating part, the nano photocatalytic net is installed above the lamp tube, and is arranged along the direction of air flow The nano photocatalytic net;

[0027] The air outlet filter device is sequentially provided with a primary filter layer, an activated carbon filter layer, a high-efficiency HEPA ultramicro filte...

Embodiment 2

[0030] It is equipped with a waste incineration rapid air purification cycle system, including an air intake bin, a heating device, a photocatalytic device and an air outlet filter device. Connected to the right, the air enters the heating device after passing through the air intake chamber, the heated air enters the photocatalytic device, and the air enters the air outlet filter device after passing through the photocatalytic device Then it is discharged from the air outlet of the air outlet filter device;

[0031] The photocatalytic device includes a nano photocatalytic net, a plasma generating part and a lamp tube, the lamp tube is arranged above the plasma generating part, the nano photocatalytic net is installed above the lamp tube, and is arranged along the direction of air flow The nano photocatalytic net;

[0032] The air outlet filter device is sequentially provided with a primary filter layer, an activated carbon filter layer, a high-efficiency HEPA ultramicro filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com