Transformer on-load tap changer oil chamber pressure online monitoring system

A technology for switching oil chambers and on-load taps, applied in the field of transformers, can solve problems such as installation angle and height of gas relays, which are difficult to observe gas, and achieve the effects of easy monitoring, convenient operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described in detail through specific examples below.

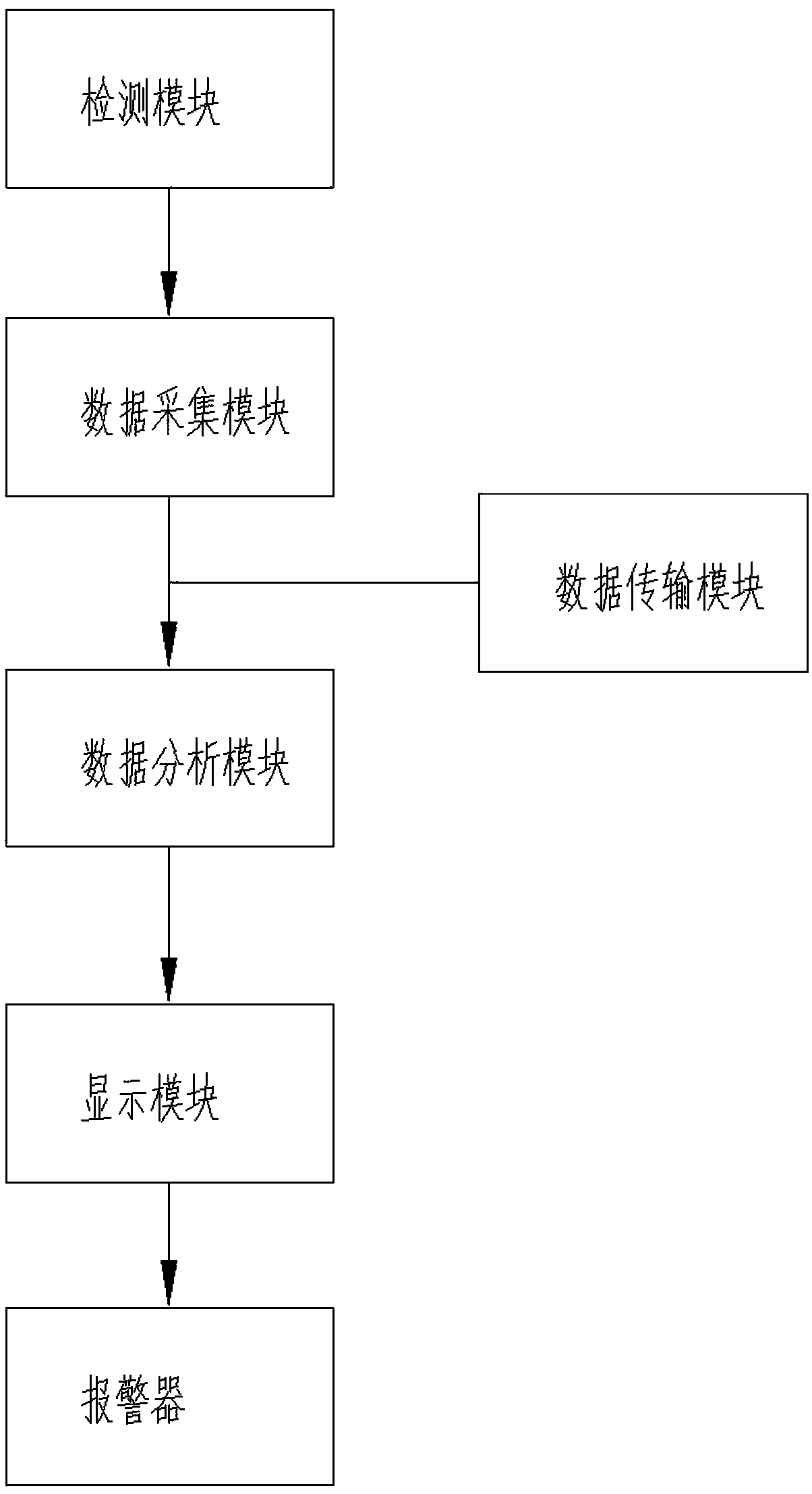

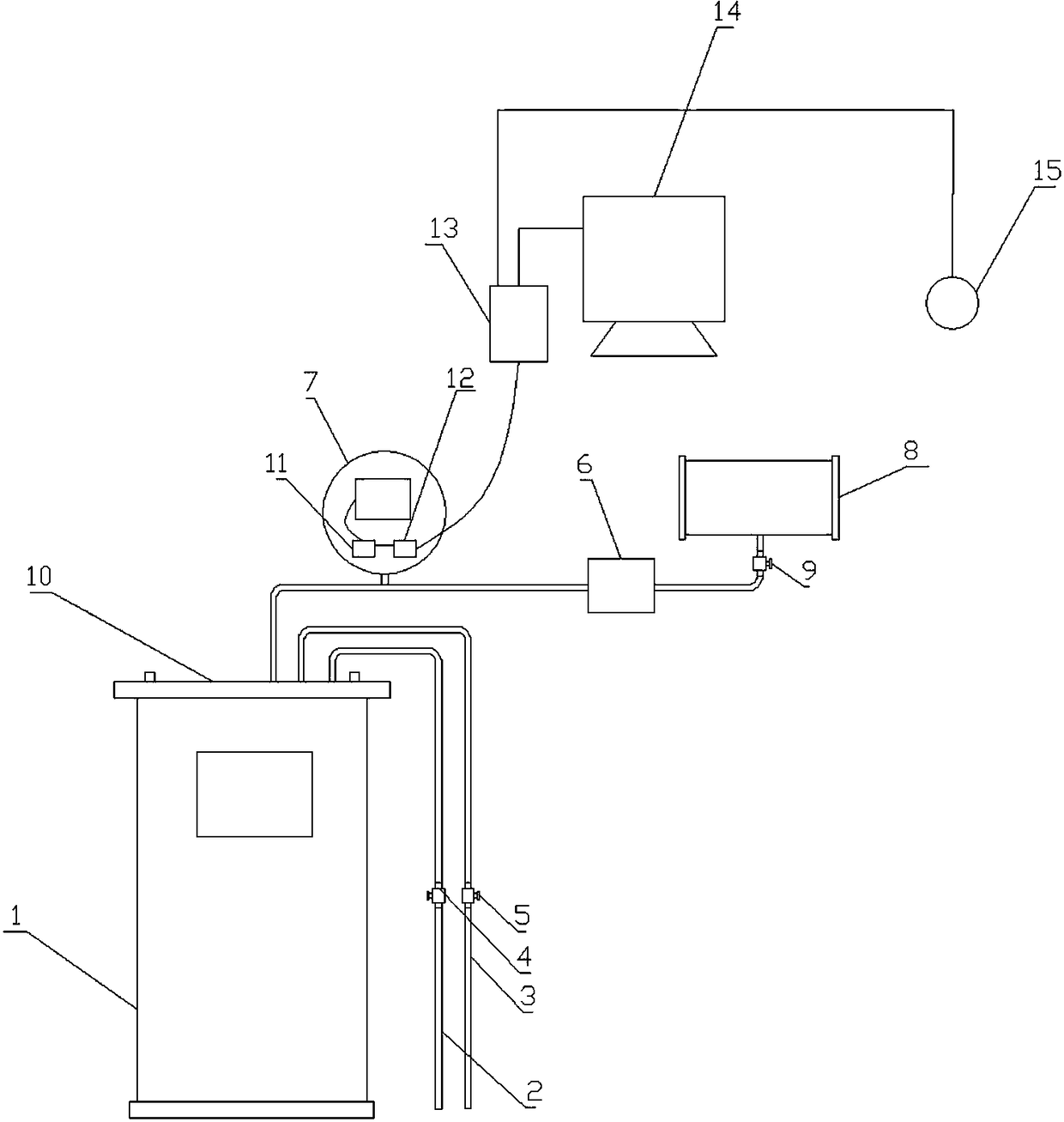

[0017] like figure 1 As shown, the present invention includes a detection module for detecting oil chamber pressure, a data acquisition module for collecting detection data, a data transmission module for transmitting the collected data, and a data analysis module for analyzing the collected data module, a display module for displaying test results, and an alarm 15 for warning of abnormal values.

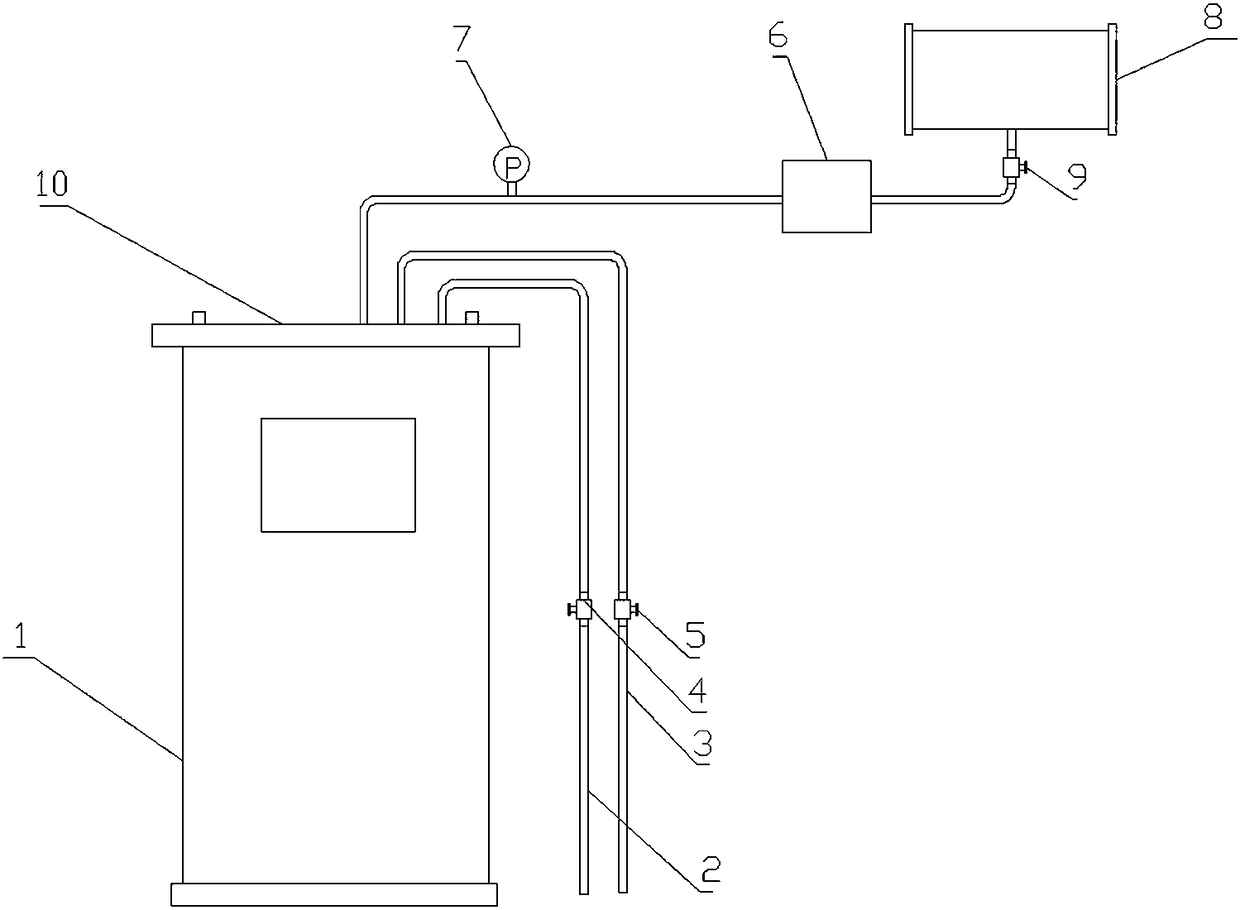

[0018] like image 3 As shown, the detection module includes a switch oil chamber 1, an oil injection pipe 3 for filling oil into the switch oil chamber 1, an oil discharge pipe 2 for discharging oil in the switch oil chamber 1, and a The oil chamber 1 is connected to the oil conservator 8 of the on-load tap changer through the pipeline; the upper end of the switch oil chamber 1 is provided with a large cover 10;

[0019] The oil injection pipe 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com