Testing device applied to jet flow scouring of hard clay

A test device and clay technology, applied in the direction of soil material testing, material inspection products, etc., can solve problems such as jet scour construction difficulties, achieve the effects of shortening the consolidation drainage process, standardizing dredging construction operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

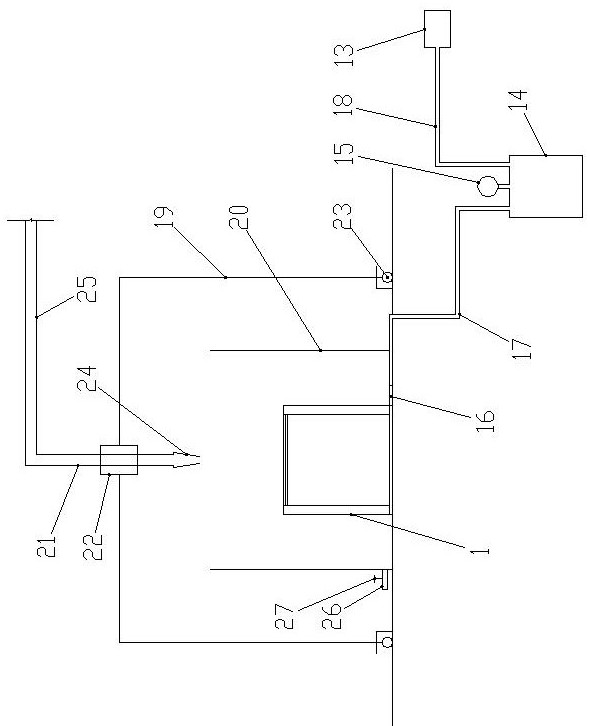

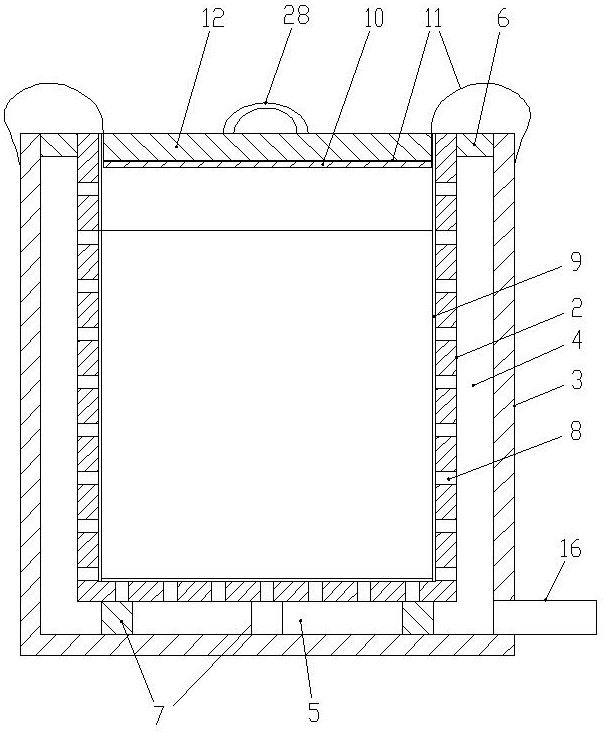

[0025] like figure 1 and figure 2 As shown, a test device for hard clay jet scouring of the present invention includes a clay consolidation assembly, a negative pressure drainage assembly and a jet scouring assembly, and the bottom of the clay consolidation assembly is connected to the inlet of the negative pressure drainage assembly. The jet scouring assembly includes a jet nozzle 24, which is located above the clay consolidation assembly and sprays water toward the clay contained inside the clay consolidation assembly.

[0026] The clay consolidation component includes a double-layer structure of the consolidation barrel 1, the double-layer structure of the consolidation barrel 1 is the inner barrel body 2 and the outer barrel body 3 arranged on the same center line, the outer circle of the inner barrel body 2 and the inner circle of the outer barrel body 3 An annular cavity 4 is formed between them, a flat cavity 5 is formed between the inner barrel body 2 and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com