Rapid dust removal structure for grain purchase and working method of rapid dust removal structure

A grain and fast technology, applied in separation methods, chemical instruments and methods, pollution prevention methods, etc., can solve the problems of polluted environment, increased dust removal burden, unsealed dust removal working environment, etc., to achieve the effect of ensuring a sealed environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

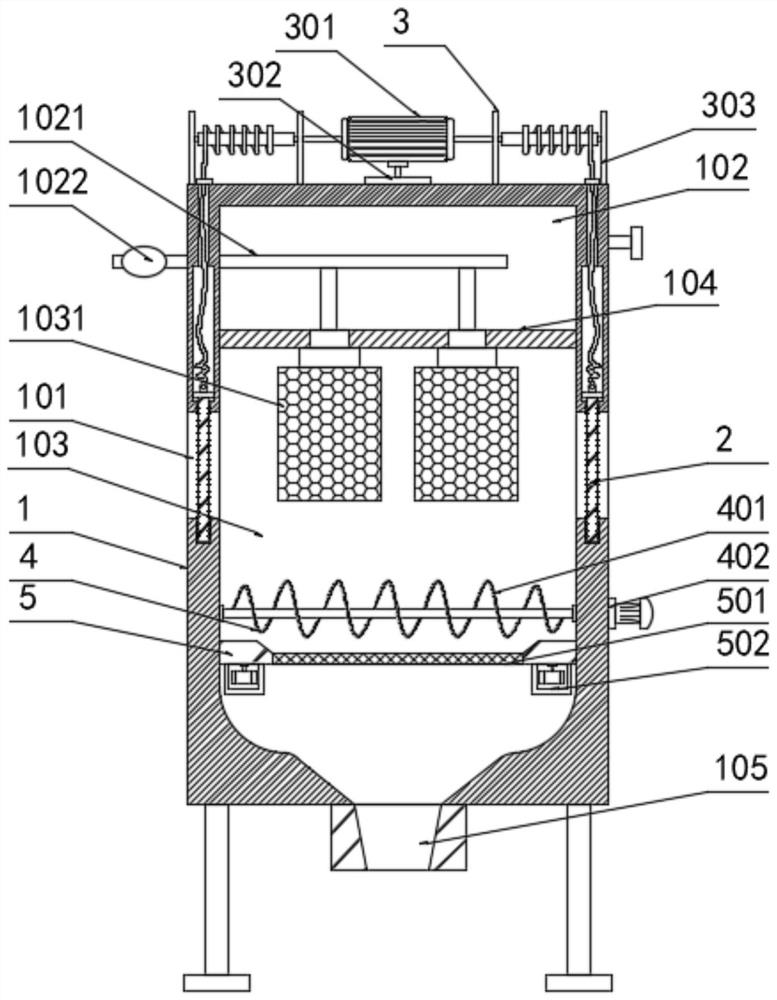

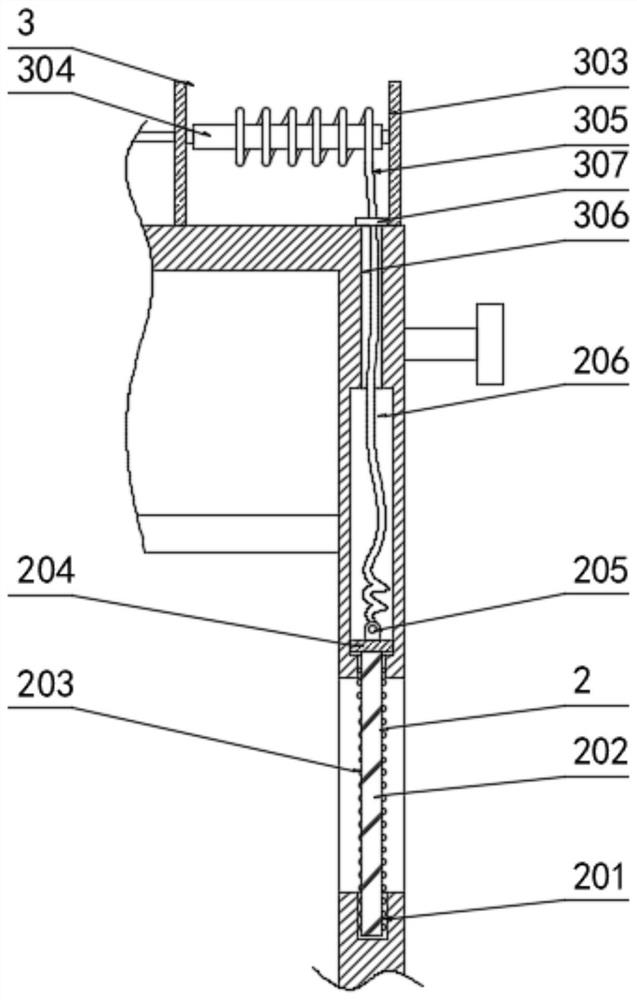

[0031] see figure 1 and figure 2 As shown, the blocking assembly 2 includes a card slot 201 arranged at the bottom of the inner cavity of the feed port 101, the inside of the card slot 201 is matched with a sealing plate 202, and the two sides of the sealing plate 202 are provided with sealing protrusions 203, and A blocking block 204 is fixedly connected to the top of the sealing plate 202, and a connecting seat 205 is installed on the top surface of the blocking block 204, and an accommodating chamber 206 slidingly connected with the blocking block 204 is provided on the top outer wall of the dust removal and screening box 1.

[0032] see figure 1 and figure 2 As shown, the winding drive assembly 3 includes a biaxial motor 301 and a support frame 302 that is arranged at the bottom of the biaxial motor 301 and is fixedly connected to the top of the dust removal and screening box 1. Two vertical plates 303 are arranged on one side of the biaxial motor 301 A winding shaft ...

Embodiment 2

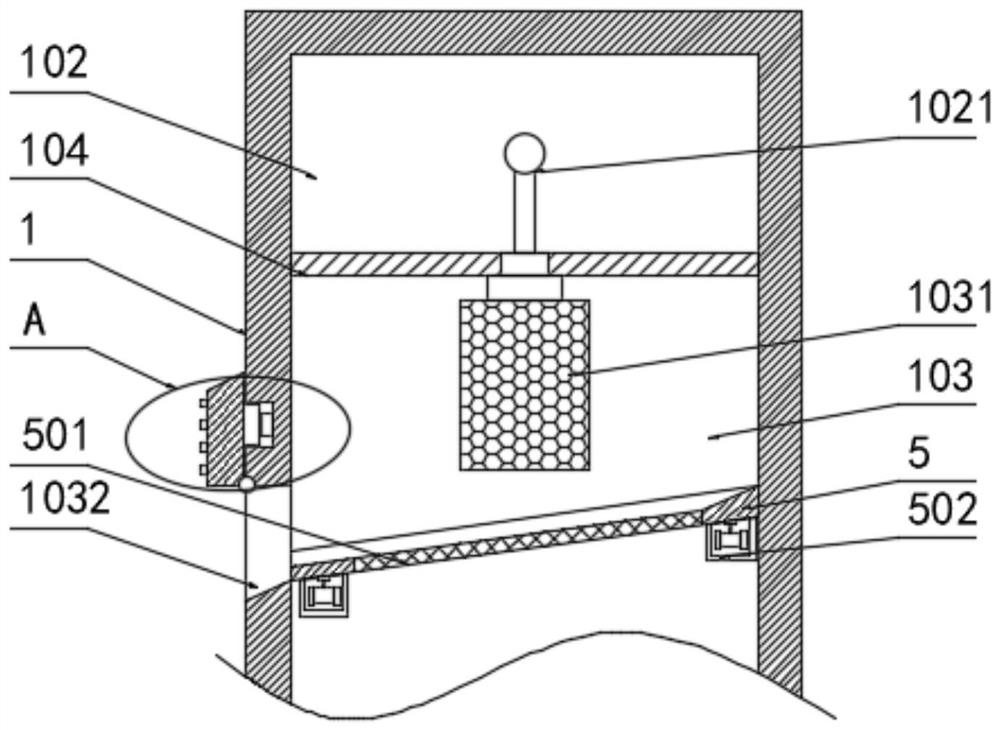

[0036] see figure 1As shown, the interior of the clean air chamber 102 is provided with a blowing pipe 1021 with a horizontal structure, and a pulse valve 1022 is installed at the end of the blowing pipe 1021. A cloth filter bag 1031 connected to the blowing pipe 1021 is installed at the bottom of the inner cavity, and a stirring assembly 4 is arranged under the cloth filter bag 1031, and a screening plate 5 is installed obliquely below the stirring assembly 4. The auger 402 on the outer wall of the screening box 1 and the servo motor 401 installed on the inner wall of the dust blowing chamber 103 and fixedly connected to the end of the output shaft of the auger 402, the servo motor 401 drives the auger 402 to stir the raw materials for grain purchase, and the clean air chamber 102 produces strong wind pressure, and the dust produced in the stirring process can be adsorbed on the outer surface of the cloth filter bag 1031.

[0037] see figure 1 , image 3 and Figure 4 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com