Cement stable sampling device and method

A sampling device and cement stabilization technology, which is applied in the field of cement stabilization sampling devices, can solve problems such as unstable negative pressure of gas, unstable sample material volume, and non-representative cement samples, so as to ensure weight and not cause waste of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

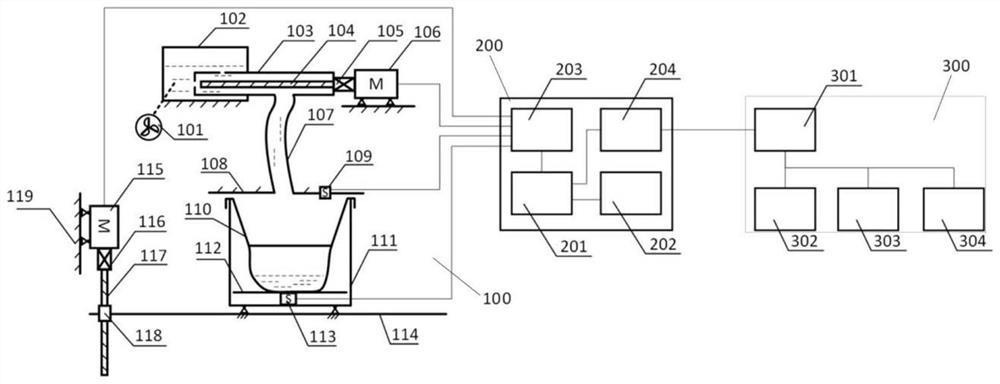

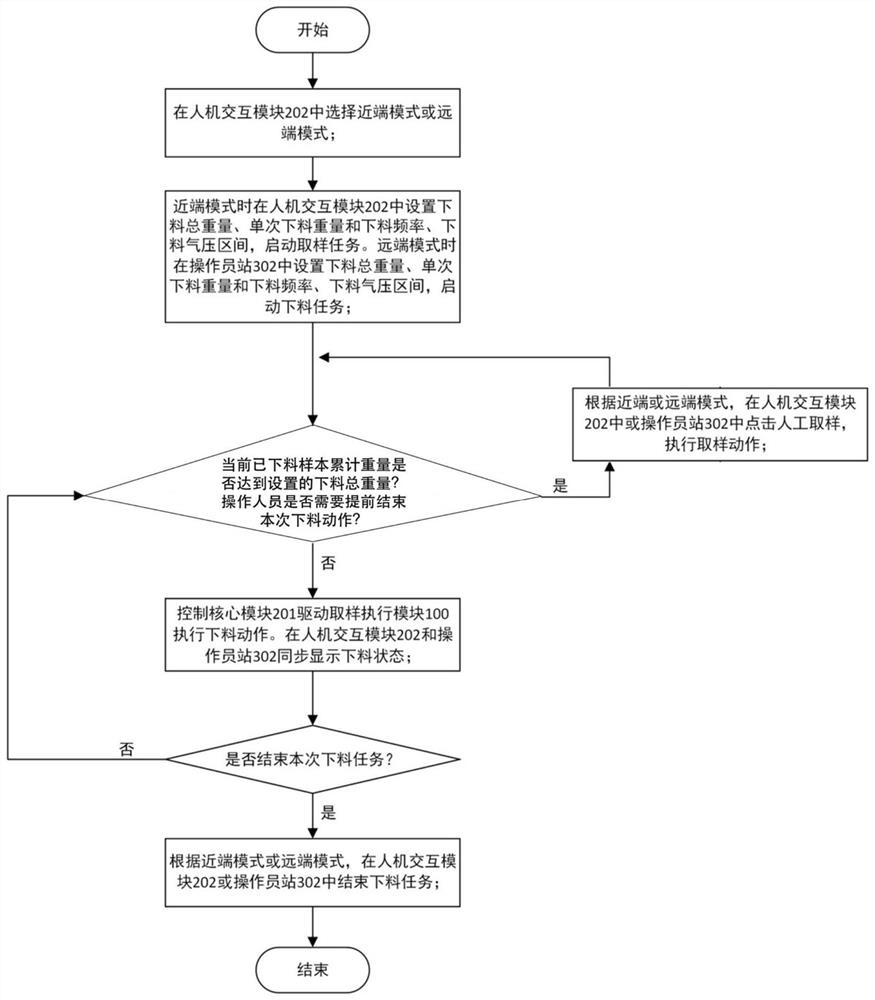

[0045] Such as figure 1 As shown, a cement stabilization sampling device includes a sampling execution system 100, a sampling control system 200, and a distributed control system 300; the sampling execution system 100 is responsible for receiving control instructions from the sampling control system 200, and completes specific cutting and sampling actions. The sampling control system 200 can set the control parameters of the blanking and sampling process, monitor the air pressure in the sampling process and the weight of the cement in the barrel in real time, and send specific control instructions to the sampling execution system 100; the distributed control system 300 supports remote setting. Material and sampling control parameters, real-time monitoring of material cutting and sampling process; sampling control system 200 and sampling execut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com