Device for detecting bottle labeling omission on production line

A detection device and production line technology, which can be applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of missing bottle labels and poor detection results of detection devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

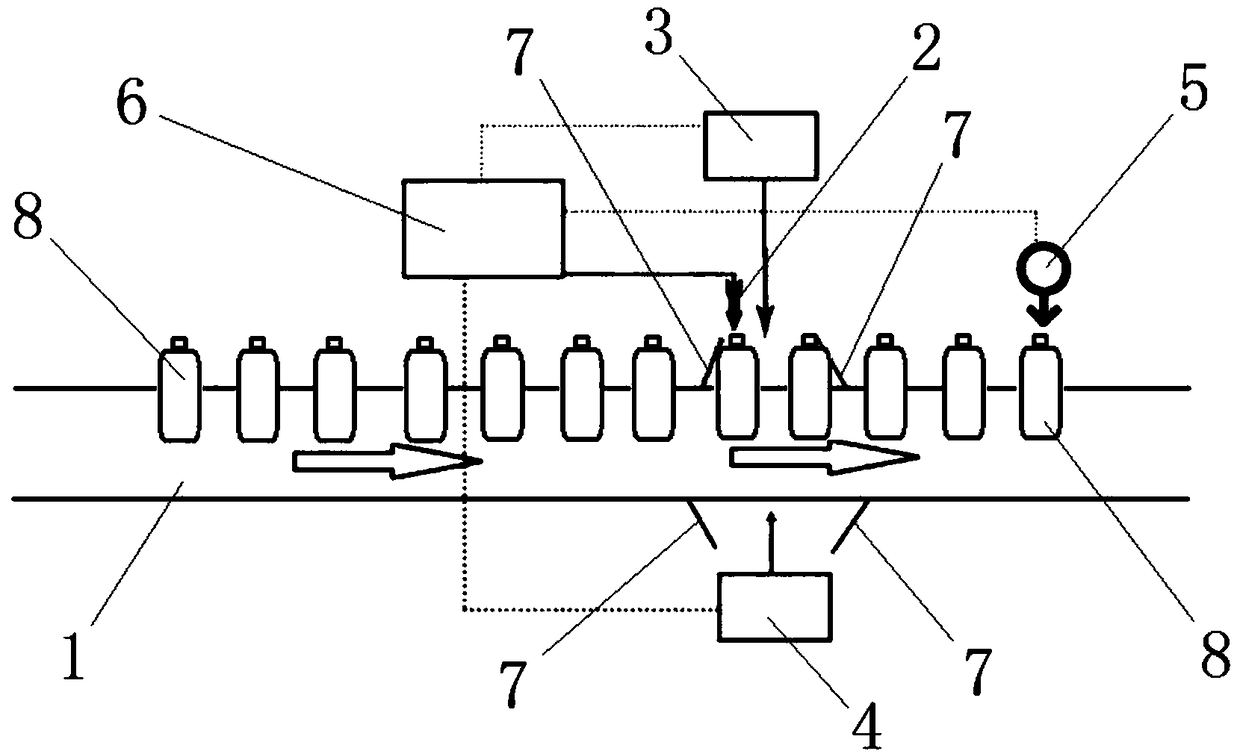

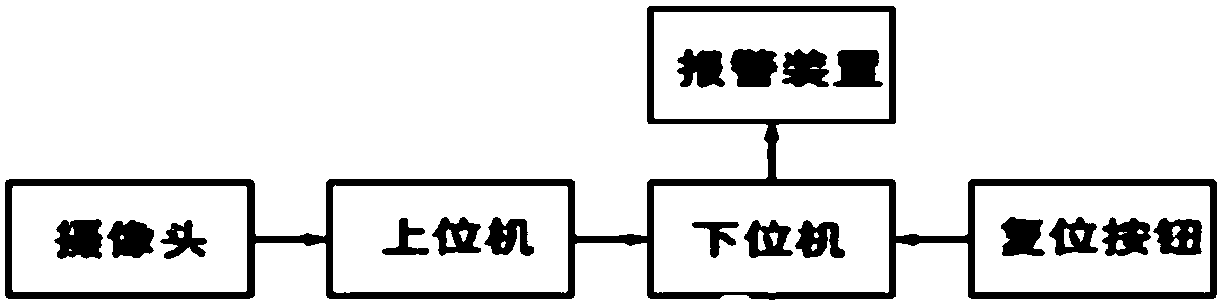

[0024] A detection device for bottle label leakage on the production line, including a conveyor belt 1, a sensor 2, a first industrial camera 3, a second industrial camera 4, a cylinder 5, a computer 6, and a plane mirror 7, wherein the sensor 2 is located above the conveyor belt 1 On one side, the straight line where the detection direction of the sensor 2 is located is perpendicular to the straight line where the conveyor belt 1 is running, and the first industrial camera 3 is located downstream of the sensor 2 with the moving direction of the conveyor belt 1 as a reference. On one side above the conveyor belt 1, the straight line where the shooting direction of the first industrial camera 3 is located is perpendicular to the straight line where the running direction of the conveyor belt 1 is located, and the second industrial camera 4 is located on the other side above the conveyor belt 1, and the second industrial camera 4 The straight line where the shooting direction of t...

Embodiment 2

[0032] A detection device for bottle label leakage on the production line, including a conveyor belt 1, a sensor 2, a first industrial camera 3, a second industrial camera 4, a cylinder 5, a computer 6, and a plane mirror 7, wherein the sensor 2 is located above the conveyor belt 1 On one side, the straight line where the detection direction of the sensor 2 is located is perpendicular to the straight line where the conveyor belt 1 is running, and the first industrial camera 3 is located downstream of the sensor 2 with the moving direction of the conveyor belt 1 as a reference. On one side above the conveyor belt 1, the straight line where the shooting direction of the first industrial camera 3 is located is perpendicular to the straight line where the running direction of the conveyor belt 1 is located, and the second industrial camera 4 is located on the other side above the conveyor belt 1, and the second industrial camera 4 The straight line where the shooting direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com