Hair dryer

A hair dryer and hair dryer technology, applied in clothing, hairdressing equipment, hair drying equipment, etc., can solve the problems of wind potential energy loss, poor thermal efficiency, large impeller design, etc., to reduce potential energy into heat energy and high-frequency vibration, The effect of novelty appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

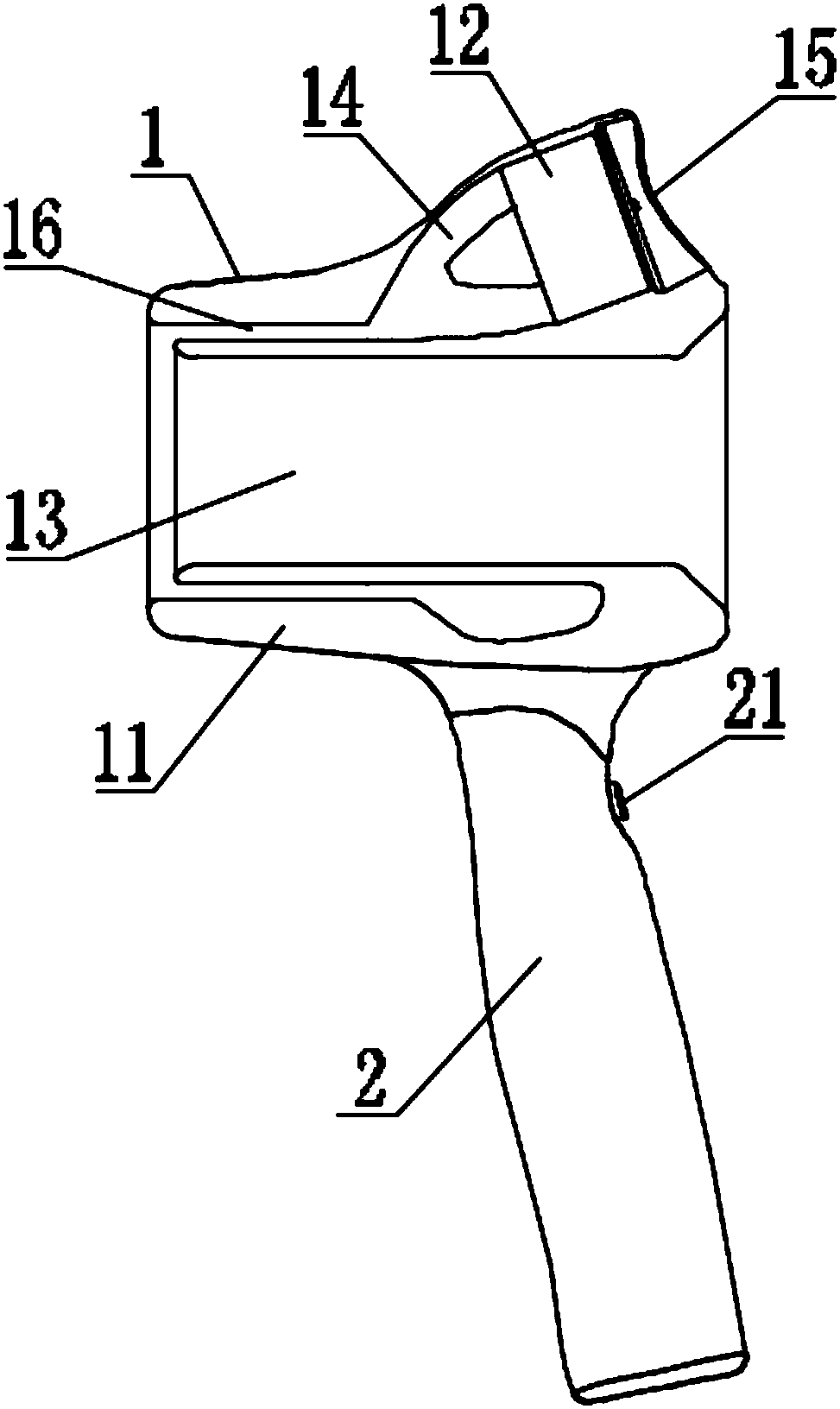

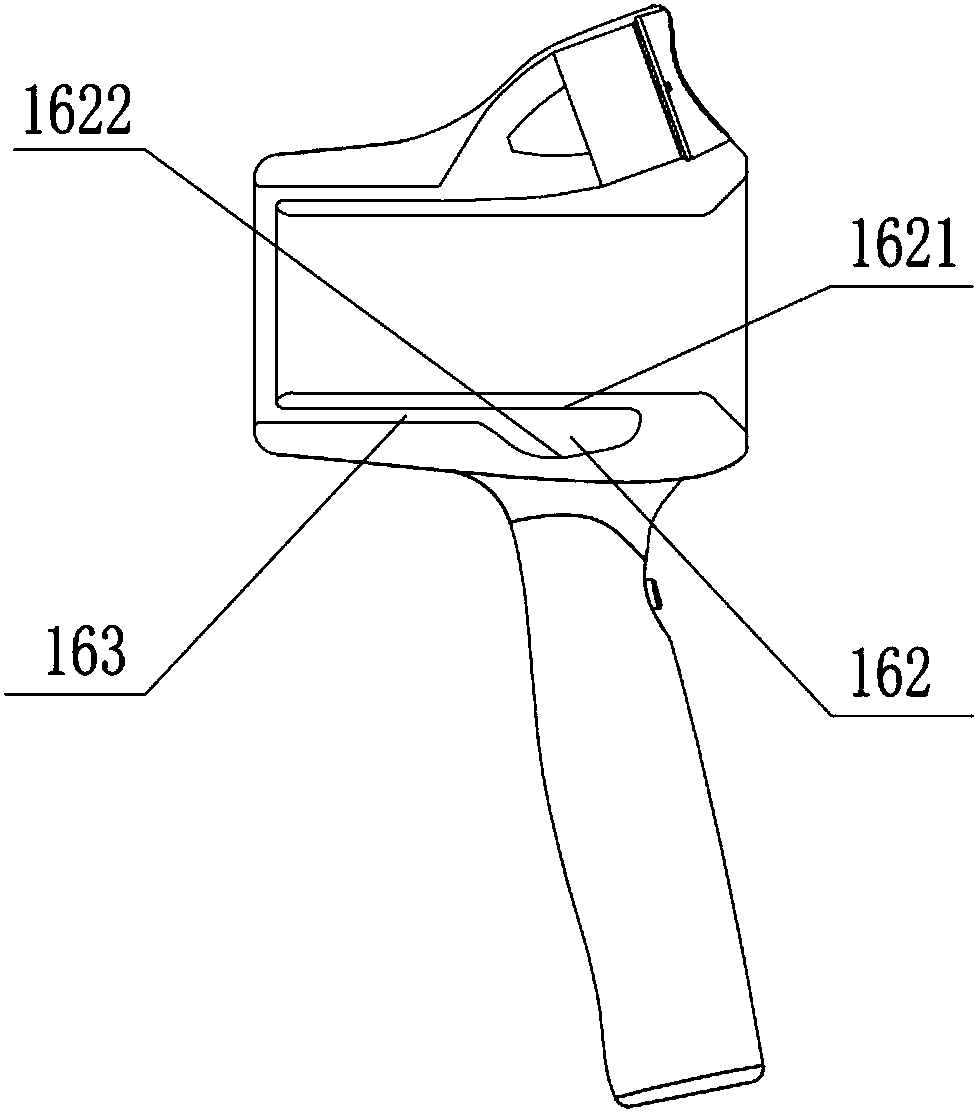

[0023] [Example 1] If figure 1 As shown, it is a structural schematic diagram of the first embodiment of the present invention. This embodiment provides a hair dryer. The hair dryer includes: an air cylinder 1 and a handle 2 connected to the air cylinder 1. The handle 2 is used for use The user holds and supports the blower 1 , the blower 1 is provided with components for generating air flow, and the handle 2 is provided with a circuit control part for controlling the blower 1 and the internal components of the blower 1 .

[0024] The blower 1 includes: a body 11 with a channel for guiding the flow of air and a motor 12 arranged in the body 11 for generating air passing through the channel. The center of the body 11 has a first air outlet channel 13. The first air outlet channel 13 runs through the body 11, forming the body 11 into an approximately hollow cylindrical structure, and the outer ring of the first air outlet channel 13 is provided with a ring that extends to the in...

Embodiment 2

[0028] [Embodiment 2] This embodiment is the second embodiment provided by the present invention. The content of this embodiment is partly the same as that of the above-mentioned embodiment, and will not be repeated here. The only difference is that the first air outlet channel The ratio of the width of 13 to the width of the second air outlet channel 16 is 10:1-2, this setting can effectively use the airflow generated by the second air outlet channel 16 to drive the airflow of the first air outlet channel 13 .

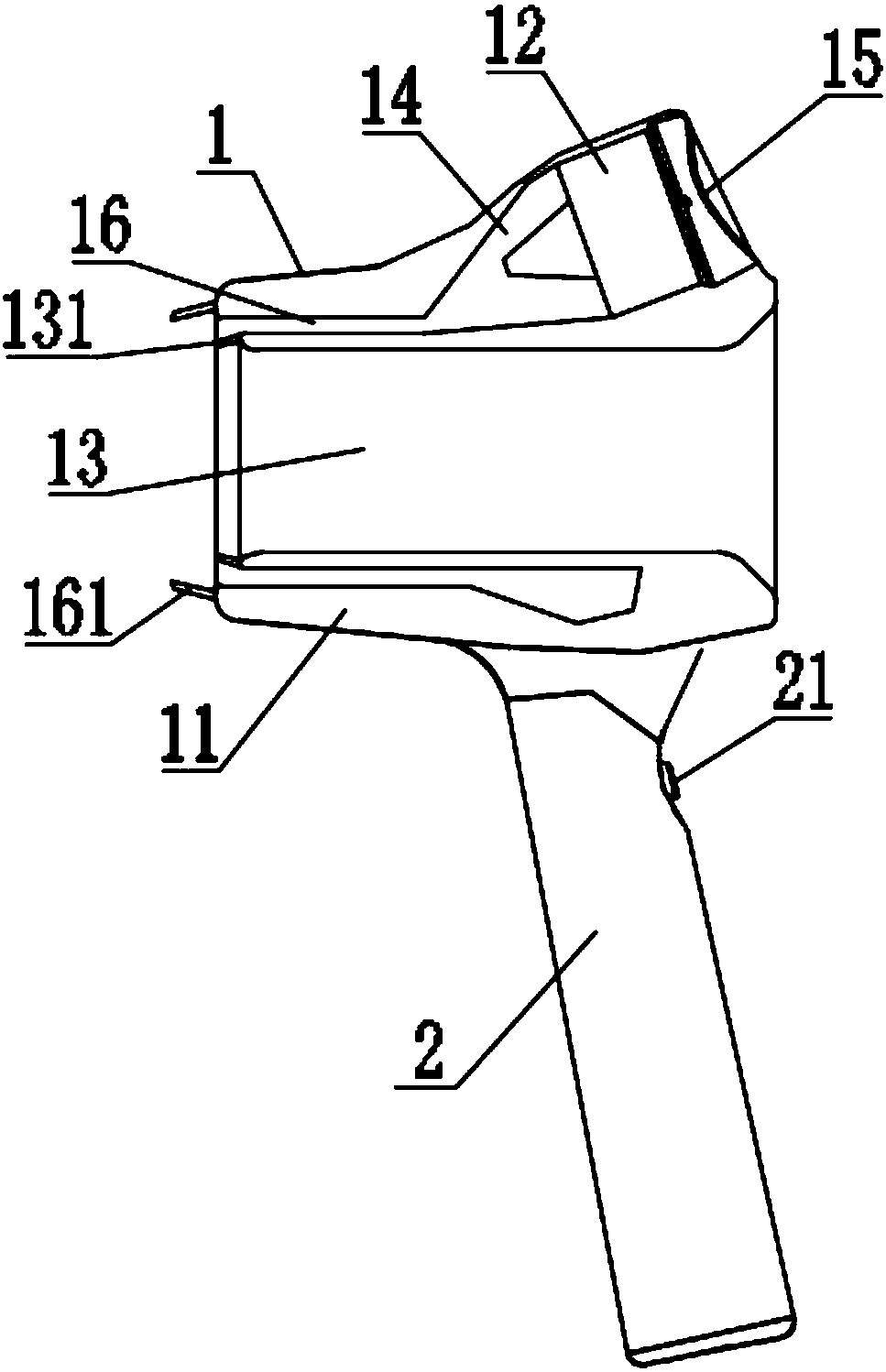

[0029] [Embodiment 3] If figure 2 As shown, it is the third embodiment provided by the present invention. The content of this embodiment is partly the same as that of the above-mentioned embodiment, and will not be repeated here. The only difference is that the air outlet of the first air outlet channel 13 is set There is an annular first guide structure 131, the angle between the first guide structure 131 and the axis of the first air outlet channel 13 is 5-15°, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com