A single-row double-spray cleaning device for high-temperature resistant filter bags

A cleaning device and high-temperature-resistant technology, which is applied in the fields of high-temperature-resistant filter bag cleaning, high-temperature-resistant filter bag cleaning device, and single-row double-spray cleaning device. Fit, small strength and other issues, to achieve the effect of improving the quality of cleaning, good cleaning quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

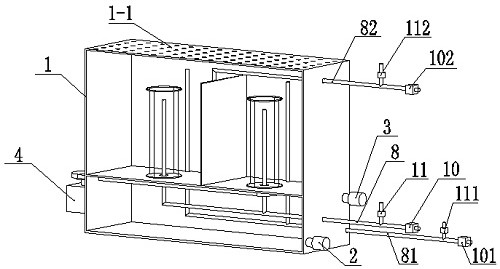

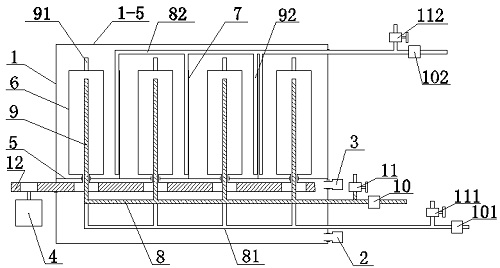

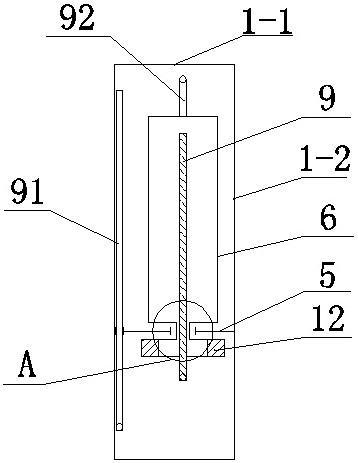

[0039] see Figure 1~Figure 7 , a single-row double-spray cleaning device for high-temperature-resistant filter bags, including a sealed box body 1, a power system, an inner bag cleaning subsystem, an upright outer bag cleaning subsystem, a side outer bag cleaning subsystem, and a sewage pump 2. Vacuum pump 3, the inside of the box 1 is horizontally provided with a leaking plate 5, the leaking plate 5 is located at the bottom of the box 1, and the leaking plate 5 is provided with a number of filter bag holders 6 and cleaning partitions 7, cleaning the partitions 7 Arranged between adjacent filter bag holders 6, the plane where the cleaning partition 7 is located is perpendicular to the plane where the front of the box body 1 is located, and a sewage pump 2 and a vacuum pump 3 are arranged on the side of the box body 1, and the sewage pump 2 and the vacuum pump 3 Arranged at a position below the horizontal plane where the leaking plate 5 is located; the power system includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com