Equipment for recycling molding sand and clearing inside and outside of centrifugal cast mold tube of turbine

A technology of centrifugal casting and recycling equipment, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of high labor intensity and low cleaning efficiency, and achieve improved resource utilization and small overall equipment , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail and completely below in conjunction with the embodiments and the accompanying drawings.

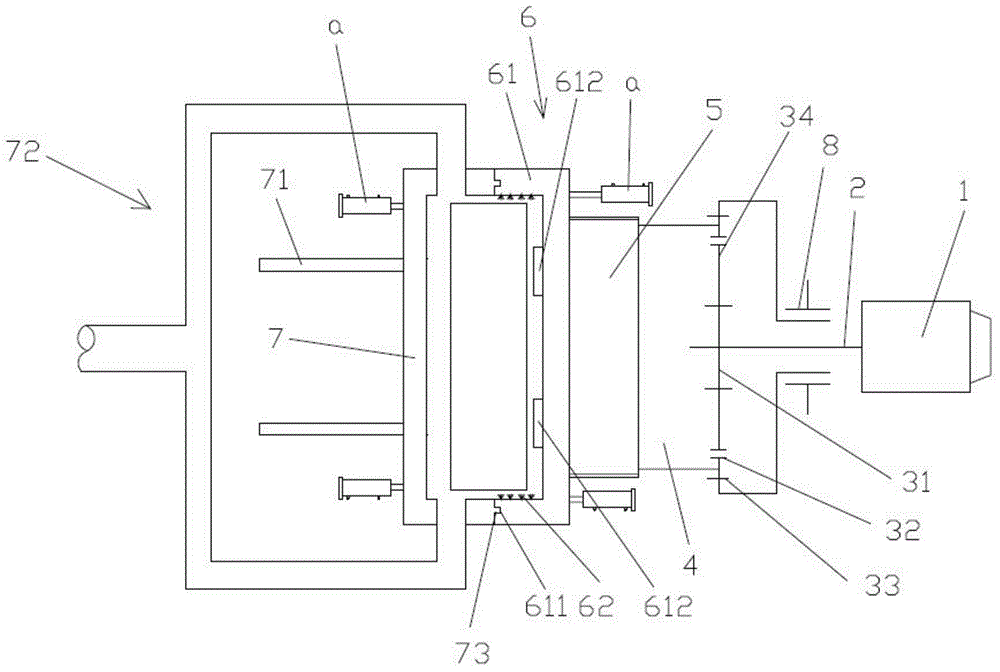

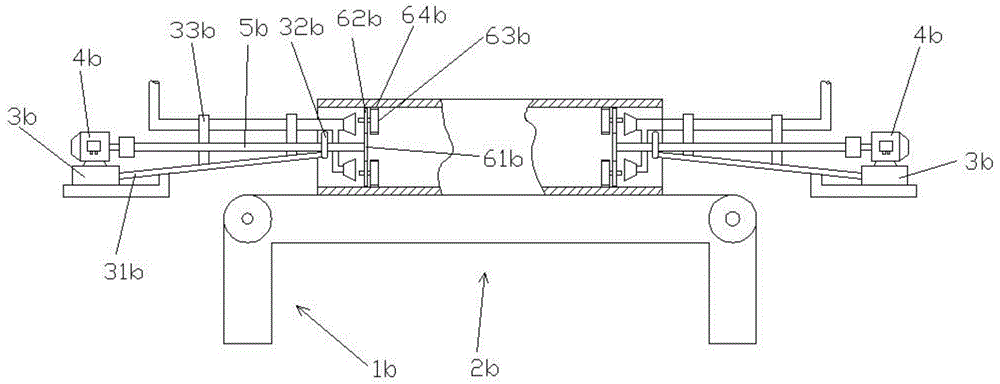

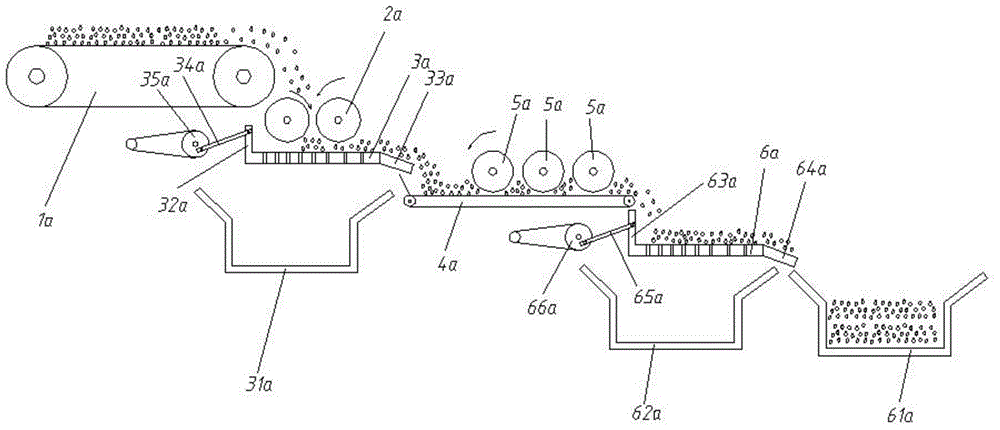

[0026] like Figure 1-3 As shown, a turbine centrifugal casting mold cylinder internal and external cleaning and molding sand recovery equipment, including external dust removal device, inner wall cleaning device and molding sand recovery device, the inner wall cleaning device includes a moving assembly for moving the casting mold cylinder and for cleaning The grinding assembly of the casting cylinder, the moving assembly includes a bracket 1b and a conveyor belt 2b arranged on the bracket 1b for carrying the casting cylinder, and the conveyor belt 2b is driven by a motor to move in both directions;

[0027] The grinding assembly includes two bases 3b, and the two bases 3b are respectively arranged on both sides of the support 1b, each of the bases 3b is equipped with a main power motor 4b, and each of the bases 3b The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com