A single-head saw for processing aluminum profiles

A technology for aluminum profile processing and processing discs, which is applied in metal processing equipment, manufacturing tools, sawing machine devices, etc., can solve problems such as inconvenient operation, affecting processing accuracy, and unsightly appearance, and achieves easy maintenance and replacement, improved processing efficiency, and increased The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

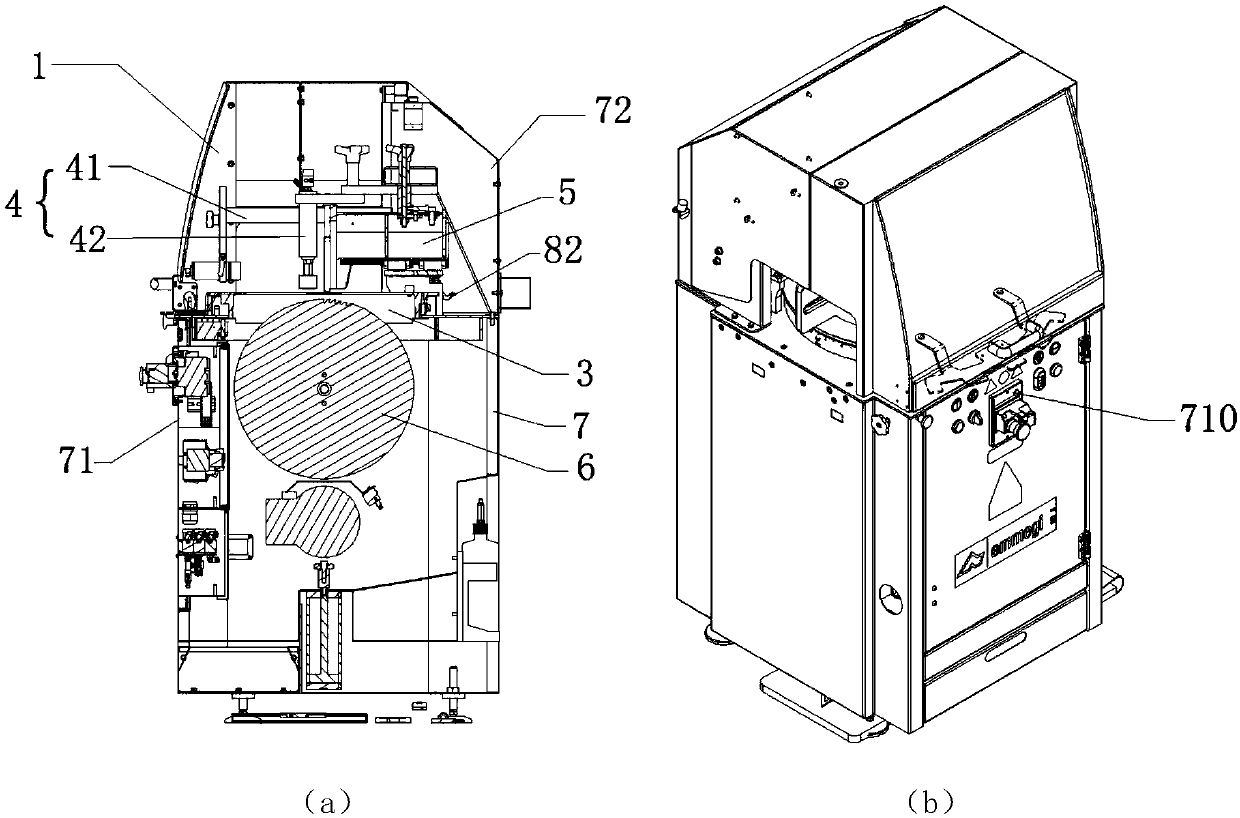

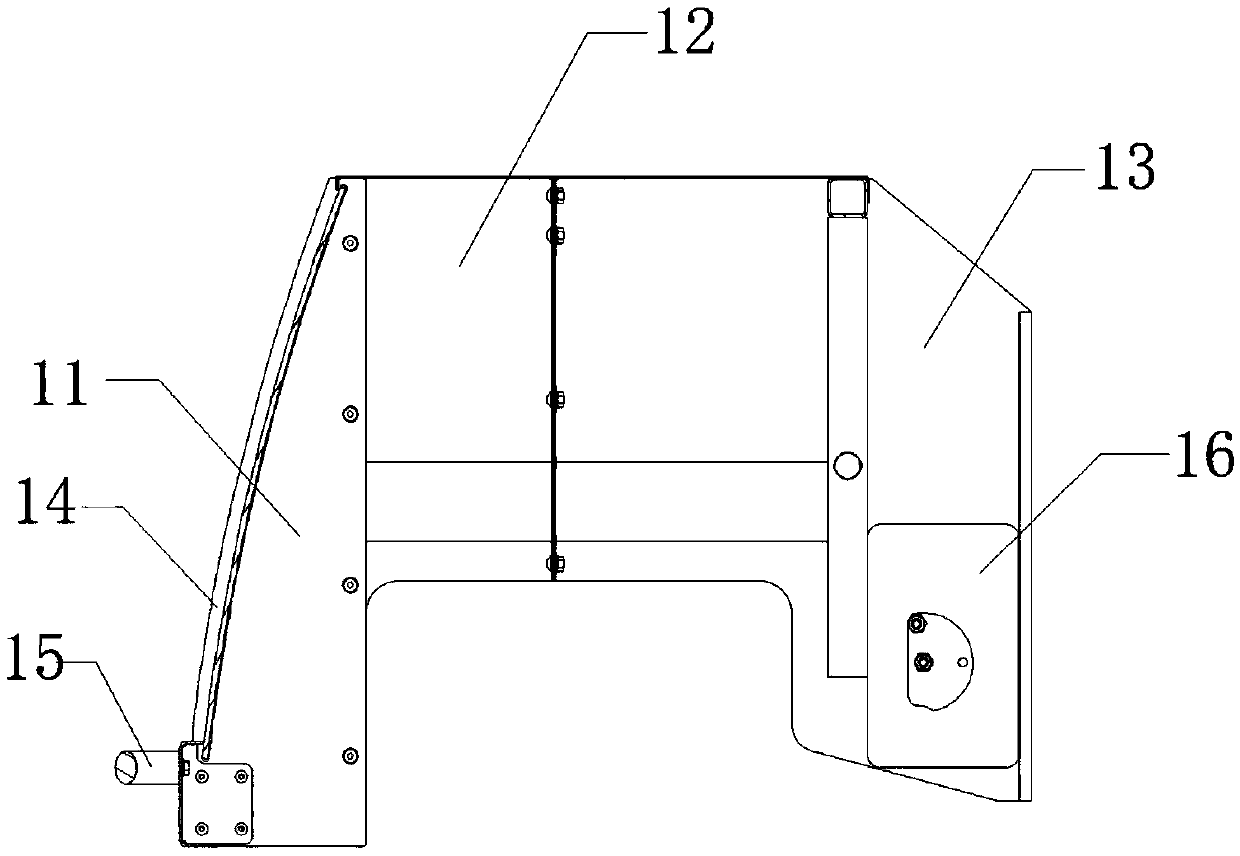

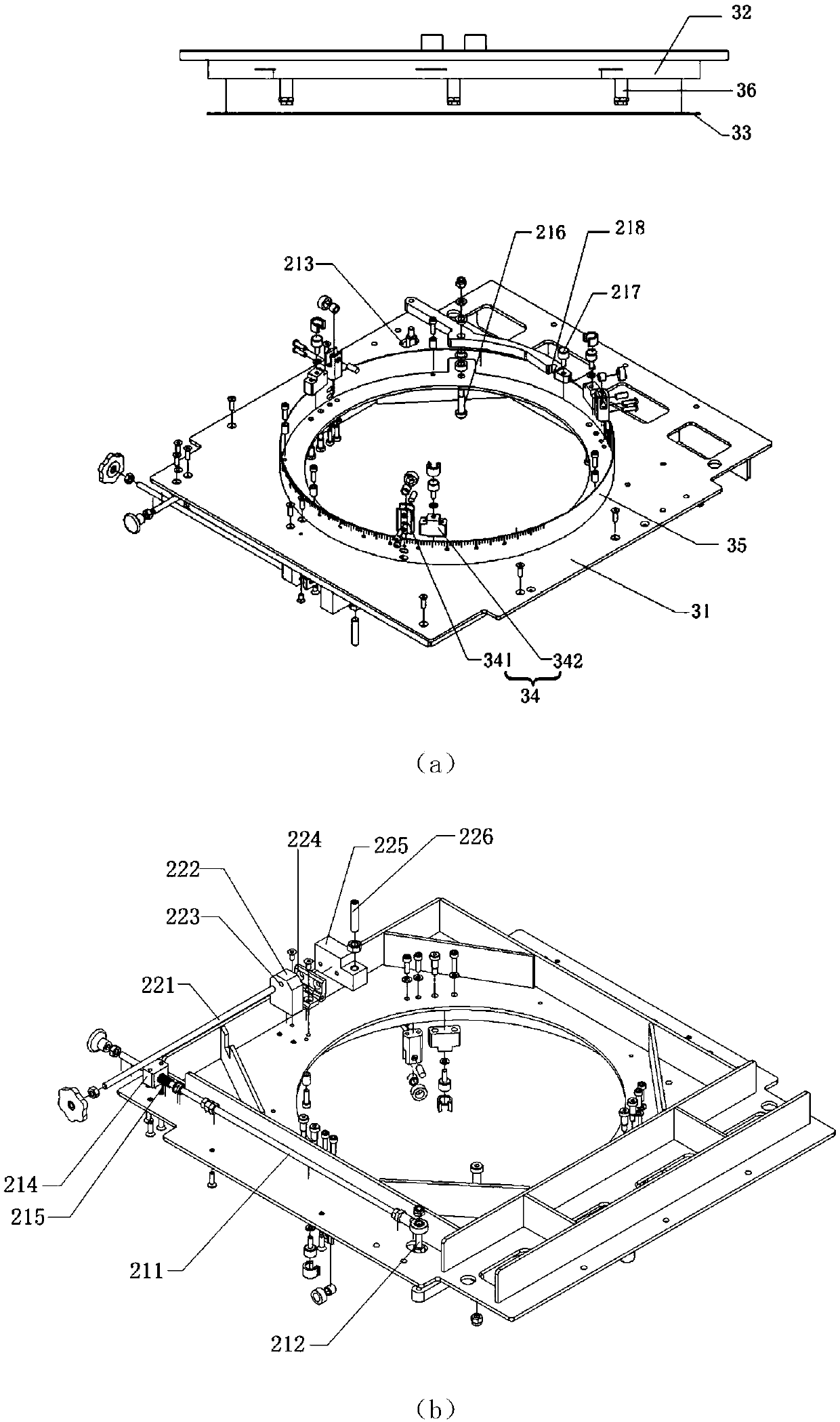

[0029] Please refer to Figure 1 to Figure 6 . A single-head saw for processing aluminum profiles proposed by the present invention includes a cabinet body 7, a workbench 3, a positioning and clamping device, a saw blade feeding device 6 and a safety cover 1, and the safety cover 1 is arranged in a hinged manner On the chassis body 7, the chassis body 7 includes a front box door 71 and a rear box panel 72, wherein a circuit system is arranged inside the front box door 71 for controlling the operation of the single-head saw, and the A control panel 710 is arranged on the front box door 71, and the control panel 710 is connected with the circuit system for the operator to operate the single-head saw; On the top of the chassis body 7; in this embodiment, a small window is provided on the rear box plate 72, and the small window c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com